Segmented spiral condensing heat exchanger

A condensing heat exchanger, condensing heat exchange technology, applied to indirect heat exchangers, heat exchanger types, heat exchanger shells, etc. The heat exchange capacity of the heat exchanger is different, and the effect of increasing the service life, improving the heat exchange capacity and extending the length

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

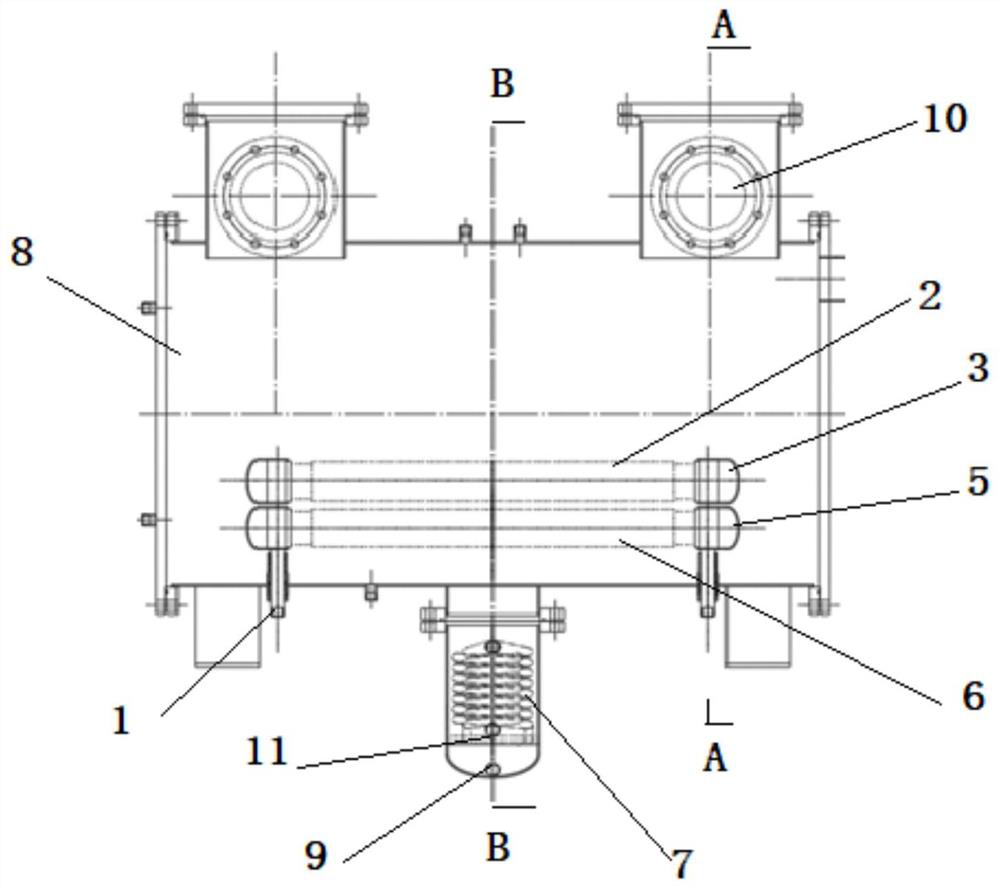

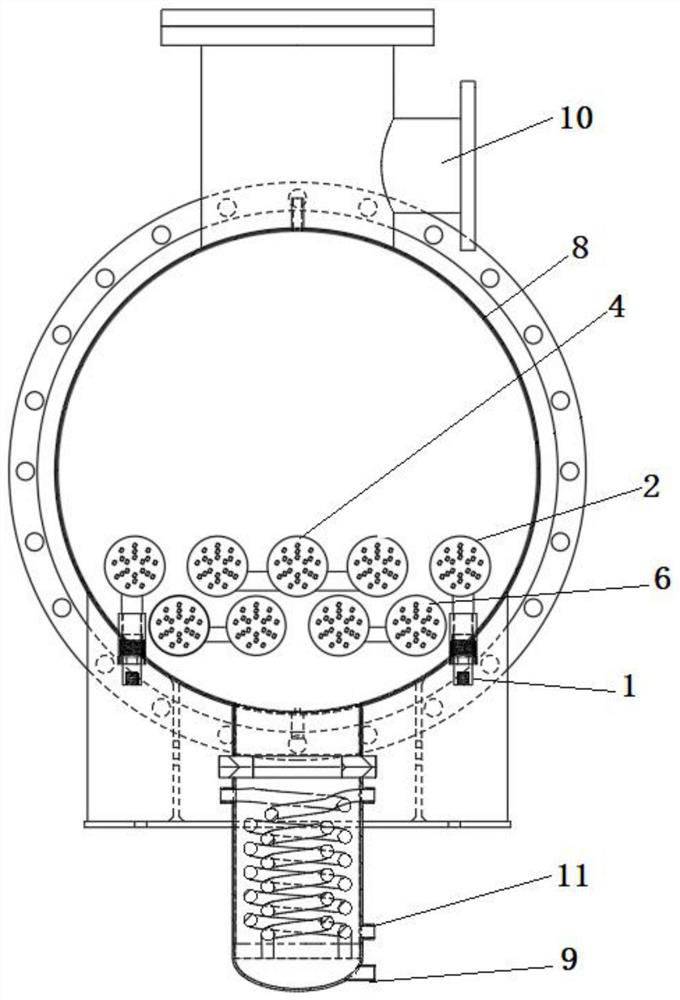

[0028] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

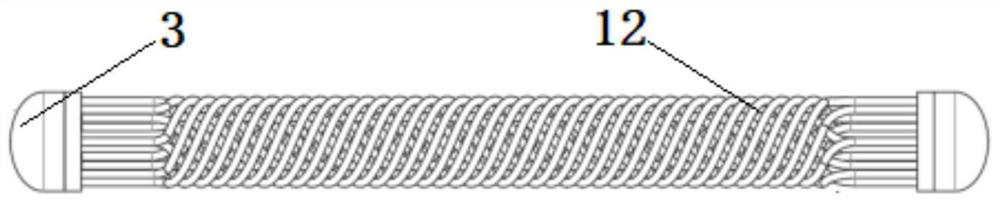

[0029] Such as Figure 1-4 As shown, a segmented spiral condensation heat exchange device includes a heat exchanger shell 8 and a heat exchange assembly installed inside the heat exchanger shell 8. The top of the heat exchanger shell 8 has a heated process The mass outlet 10 has a supporting structure at the bottom; the heat exchange components are connected in series and parallel, and are divided into top and bottom; the top is provided with a parallel spiral heat exchanger 2 and a spiral condensation heat exchanger 4 ; The bottom is provided with a parallel secondary spiral condensing heat exchanger 6, and the spiral superheat heat exchanger 2 and the primary spiral condensing heat exchanger 4 are connected through a primary tangential swirl uniform distribution chamber 3, and the secondary spiral Type condensing heat exchangers 6 are comm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com