Data collection device for switch cabinet sensor

A technology of data collection and switchgear, which is applied in the direction of measuring devices, instruments, measuring electricity, etc., can solve the problems of general detection accuracy, inability to obtain accurate data, and inability to know the data value of power distribution cabinets, etc., to achieve the goal of improving accuracy Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

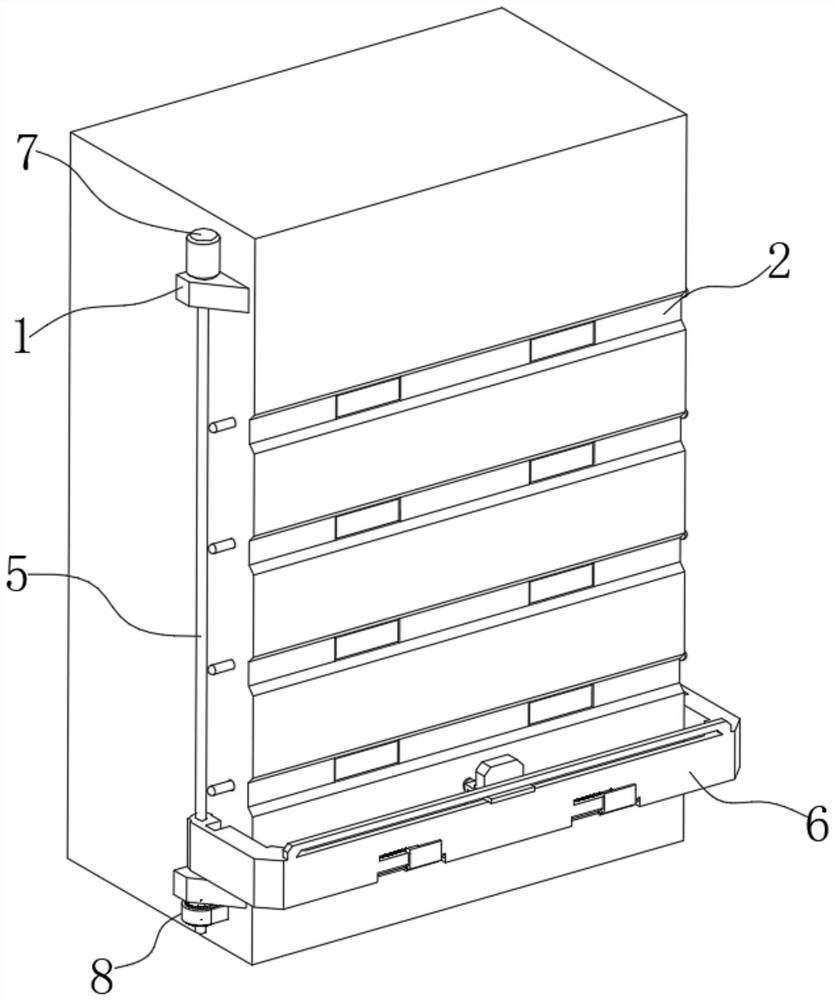

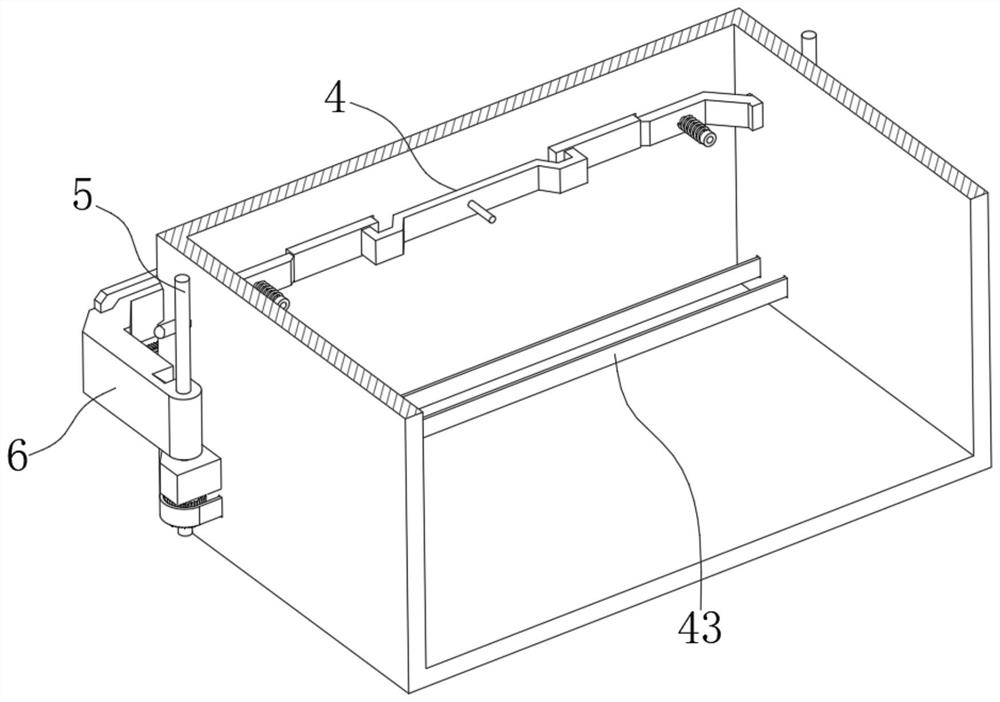

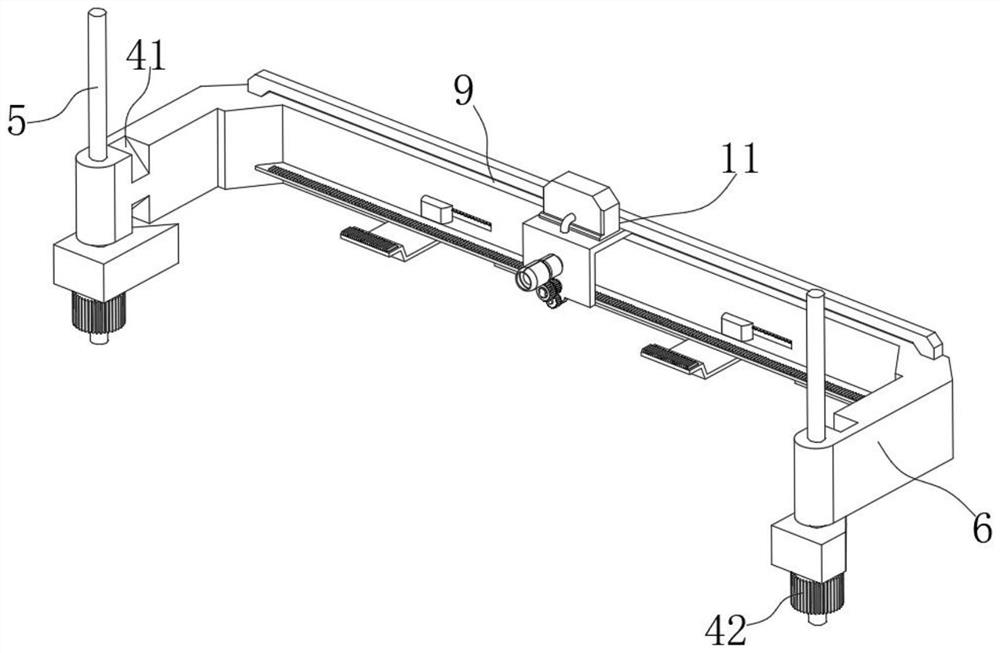

[0027] see figure 1 , figure 2 with Figure 9 , a data collection device for switchgear sensors in the figure, including fixed blocks 1 fixed on the top and bottom of both sides of the switchgear, and a plurality of grooves 2 are opened on the back side of the switchgear. There are two detection ports 3, and a closure 4 is installed at the position corresponding to the detection port 3 inside the switch cabinet, and an adjustment screw 5 is inserted between the two fixed blocks 1 on the same side, and the two adjustment screw rods 5 The outer thread is sleeved with a U-shaped plate 6, the drive motor 7 is fixed on the outside of the switch cabinet, and the output end of the drive motor 7 is fixed to the outer end of one of the adjusting screw rods 5, and the bottom of the two adjusting screw rods 5 is fixed with a linkage 8, The U-shaped plate 6 is provided with a moving port 9, and an L-shaped mobile station 10 is slidably inserted into the mobile port 9, and a data collec...

Embodiment 2

[0041] see Figure 4 with Figure 8 , this embodiment is further described for Example 1. The U-shaped plate 6 in the illustration is provided with an adjustment port 28 at the position corresponding to the detection port 3. A slide bar 29 is fixed inside the adjustment port 28, and the outside of the slide bar 29 is slidingly sleeved with Adjusting platform 30, the outer side of slide bar 29 is covered with extrusion spring 44 to push adjusting platform 30, and the outer end of adjusting platform 30 is fixed with L-shaped support platform 31, and the outer end of L-shaped support platform 31 is fixed with second tooth plate 32. One end of the rod 19 is fixed with a half gear 33 meshing with the second gear plate 32 , and the other end is fixed with a contact ball 34 that matches the adjustment platform 30 , and the outside of the transmission rod 19 is covered with a return spring for pushing the transmission gear 21 45.

[0042] It is worth noting that: in order to improve...

Embodiment 3

[0045] see image 3 with Figure 9 , this embodiment is further described for other embodiments. The closure member 4 in the illustration includes a sealing plate 36 inserted in the two detection ports 3, a connecting plate is fixed between the two sealing plates 36, and the two sealing plates 36 The outer sides are fixed with adjustable slant plates 37, and both the adjustable slant plates 37 and the connecting plates are slidingly inserted with limit pins 38 fixed to the inner wall of the switch cabinet, and the outer sides of the limit pins 38 at both ends are covered with return springs 39. Both ends are plugged with adjusting rods 40 that are in contact with the slope of the adjusting slant plate 37 , and there are adjusting grooves 41 at the positions corresponding to the adjusting rods 40 on both sides of the U-shaped plate 6 .

[0046] It should be noted that: every time the U-shaped plate 6 moves at the position corresponding to the groove 2, the adjustment rod 40 wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com