Biological alcohol oil production equipment and method thereof

A production equipment, bio-alcohol oil technology, applied in chemical instruments and methods, chemical/physical processes, mixers, etc., can solve the problems of mixed liquid stratification, poor overall hygiene, and many impurities in bio-alcohol oil, to ensure stability The effect of stability, convenience and cleaning, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

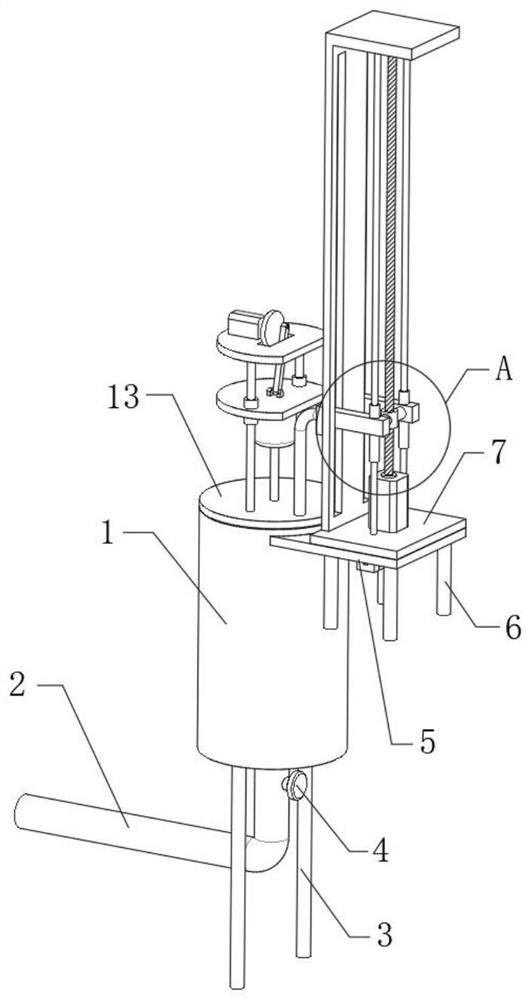

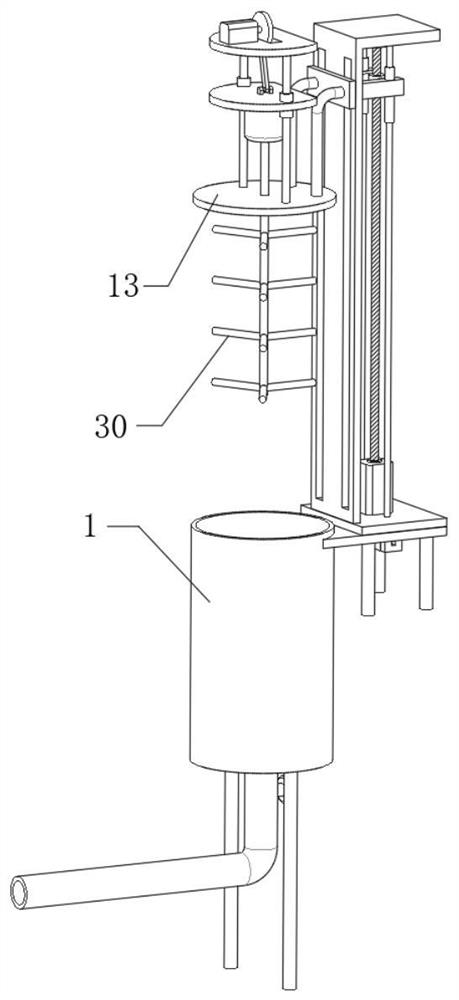

[0036] The embodiment of the present invention discloses a kind of bioalcohol oil production equipment, such as Figure 1-6 shown, including:

[0037] Production equipment mixing cylinder 1, the bottom of production equipment mixing cylinder 1 is fixedly connected with feeding pipe 2, and the side wall of production equipment mixing cylinder 1 is fixedly connected with side loading platform 5;

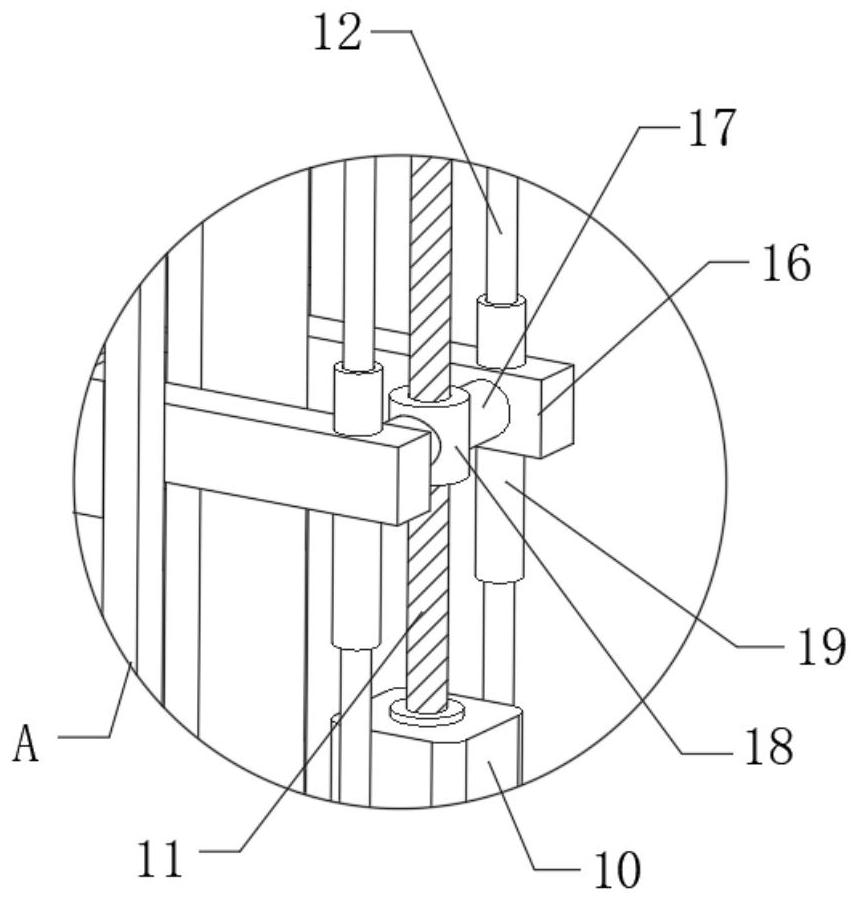

[0038] Install the docking base 7, the installation docking base 7 is fixedly connected on the side loading platform 5, and the top of the installation docking base 7 is provided with a lifting mechanism;

[0039] The lifting control platform 13, the lifting control platform 13 is fixedly installed on the lifting mechanism, the top of the lifting control platform 13 is provided with a reciprocating mechanism, the bottom of the reciprocating mechanism is provided with a third motor 28, and the output end of the third motor 28 is fixedly connected with The rotating shaft 29, the bottom ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com