Unmanned aerial vehicle delivery intelligent oil injection robot and method

A technology of robots and unmanned aerial vehicles, which is applied in the direction of aircraft parts, mechanical equipment, engine components, etc., can solve the problems of harsh environment, high production cost and improper use of the sky wheel device, so as to achieve safe production and The effect of reducing personnel and increasing efficiency, improving efficiency and operating safety, and avoiding safety accidents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

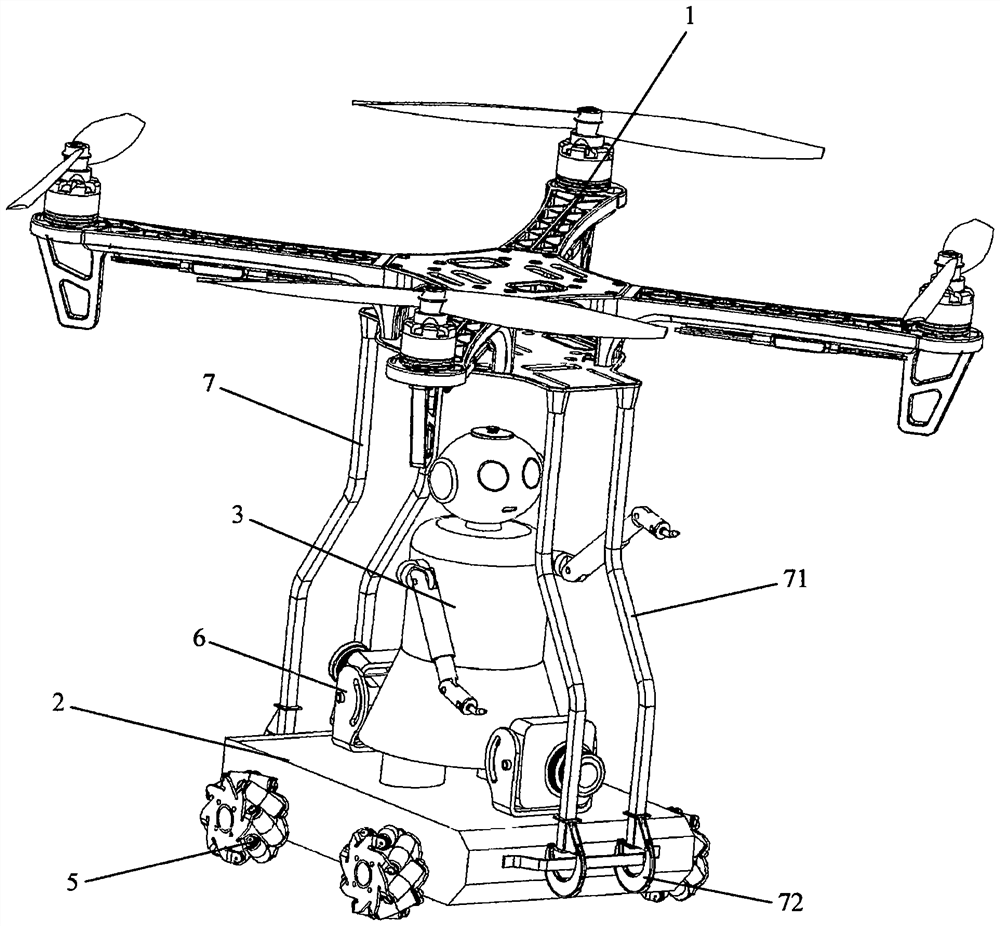

[0071] See attached Figure 2 The traveling trolley 2 is connected with the rotorcraft 1 through the hanging pieces 7, and is located below the rotorcraft 1. The number of the hanging pieces 7 is four, and all of them include a bent rod 71 and an electric hook 72. The top end of that bent rod 71 is fix with the bottom surface of the rotorcraft 1; The electric hook 72 is fixed at the bottom end of the bent rod 71 and hooked with the edge of the walking trolley 2. The front and rear outer walls of the traveling trolley 2 are fixed with handles 21, and the electric hooks 72 are hooked on the handles 21.

Embodiment 2

[0073] See attached Figure 8 And further comprises a box body 8; The box body 8 has a rectangular box structure, the outer top wall of the box body 8 is connected with the bottom surface of the rotorcraft 1 through an electric hook 9, one side wall of the box body 8 is a hinged door 81, and the traveling trolley 2 is placed inside the box body 8 on the inner bottom surface of the box body 8.

[0074] The bottom edge of the hinged door 81 is hinged with the bottom wall edge of the box body 8, and the top edge of the hinged door 81 is buckled with the top wall of the box body 8 through an electric switch. A hydraulic cylinder for controlling the opening and closing of the hinged door 81 is installed inside the box body 8.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com