Printing ink and ink-jet printing method

A printing ink and inkjet printing technology, which is applied in the direction of ink, electric solid devices, semiconductor devices, etc., can solve the problem of uneven film surface, achieve the effects of ensuring fluidity, improving film surface uniformity, and improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

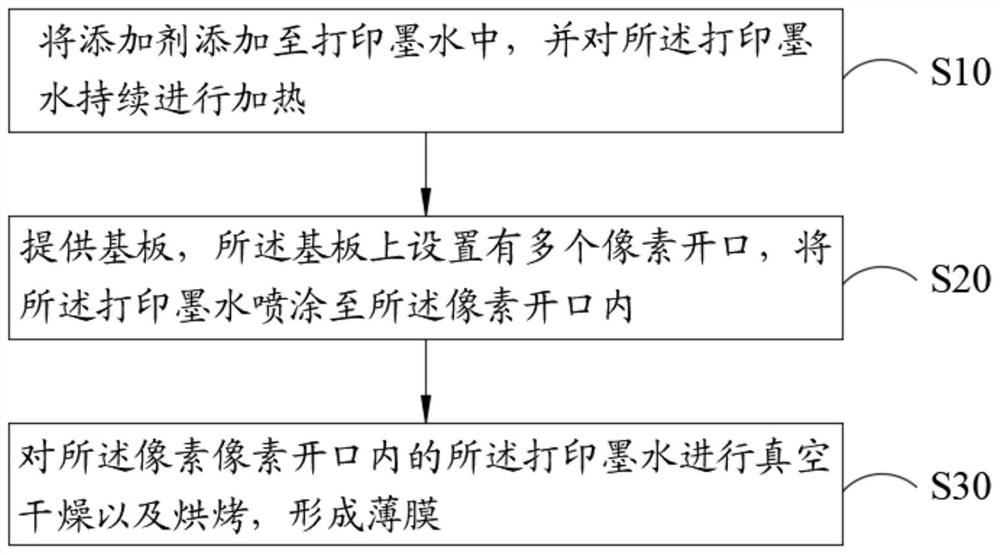

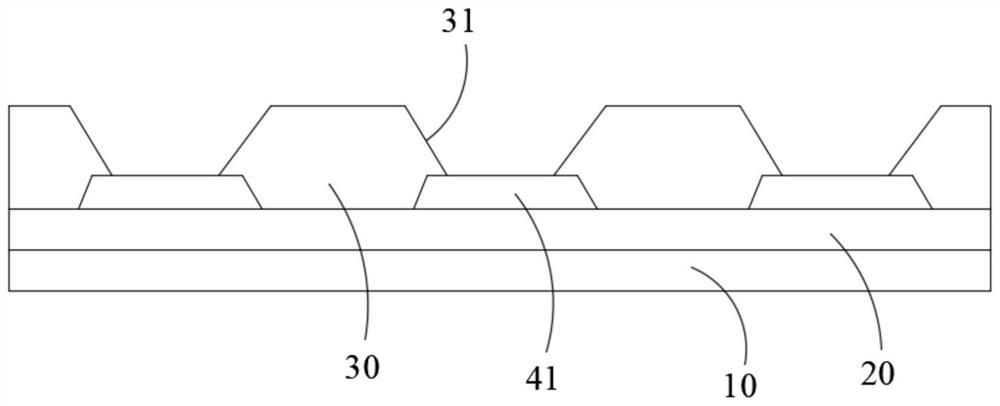

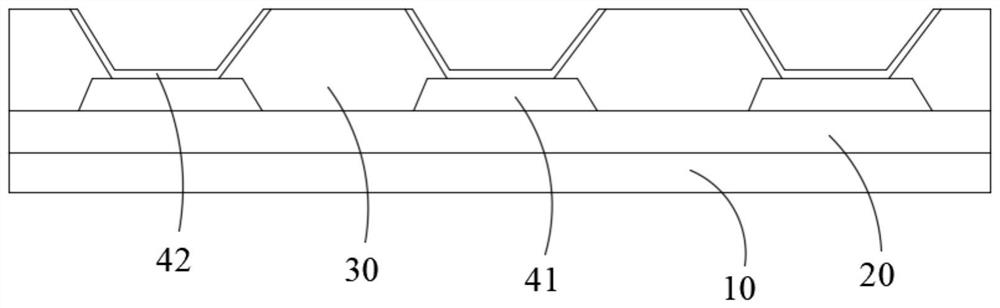

[0030] The following descriptions of the various embodiments refer to the accompanying drawings to illustrate specific embodiments that the present application can be used to implement. The directional terms mentioned in this application, such as [top], [bottom], [front], [back], [left], [right], [inside], [outside], [side], etc., are for reference only The orientation of the attached schema. Therefore, the directional terms used are used to illustrate and understand the application, but not to limit the application. In the figures, structurally similar elements are denoted by the same reference numerals.

[0031] The present application will be further described below in conjunction with the accompanying drawings and specific embodiments.

[0032] At present, in the process of vacuum drying, since the viscosity and fluidity of the printing ink cannot be effectively controlled, the solute particles in the printing ink move to the periphery of the ink drop and produce a coffe...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap