Self-propelled drag suction type dredger drag head with automatic adjusting function

A trailing suction dredger, automatic adjustment technology, applied to mechanically driven excavators/dredgers, earth movers/shovels, construction, etc., to achieve anti-sedimentation, ensure durability, and improve efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

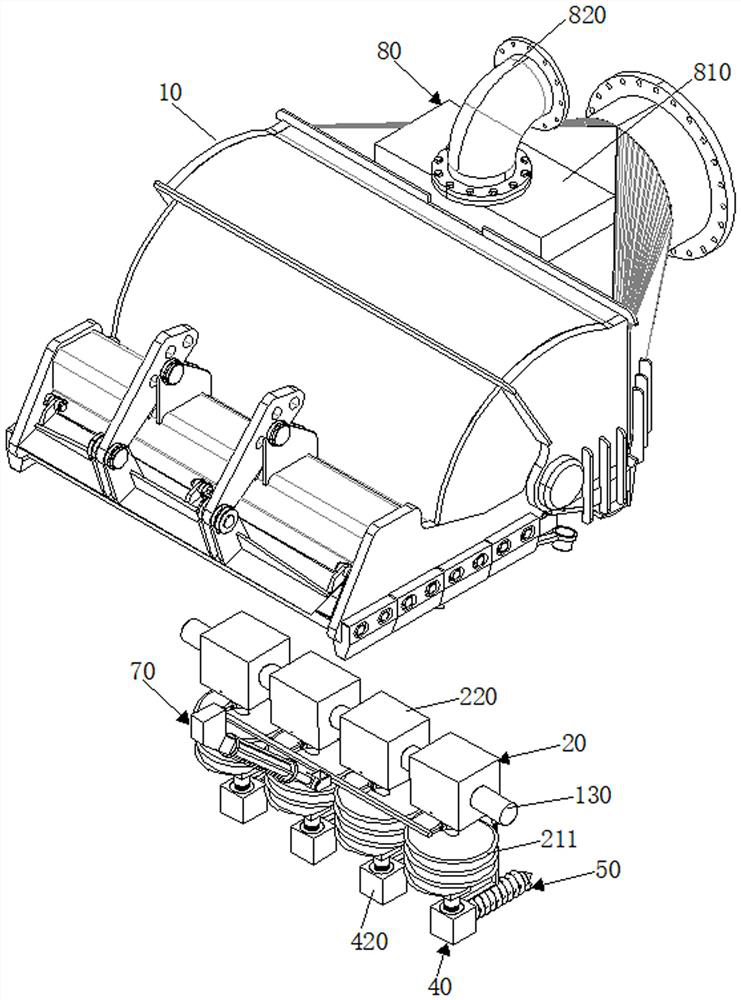

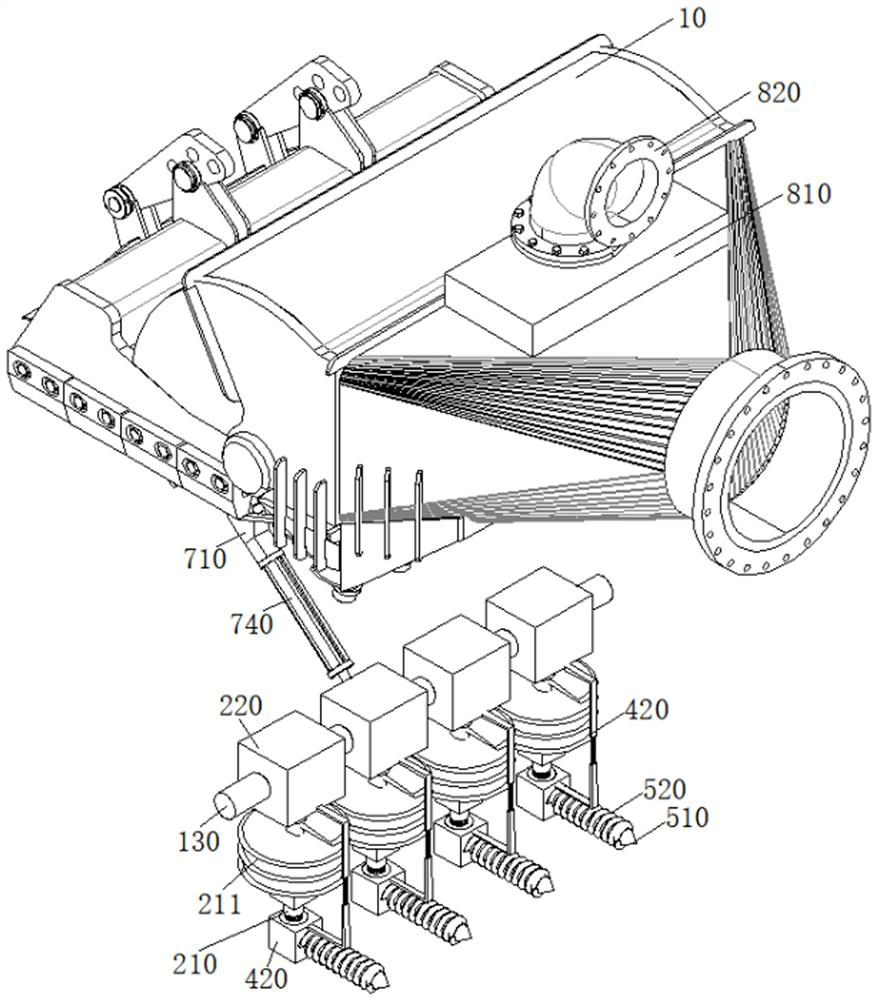

[0050] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 , Figure 7 and Figure 8 As shown, this embodiment proposes a self-propelled drag suction dredger drag head with an automatic adjustment function, including a drag head cover 10, a mounting column 110 installed at the front end of the drag head cover 10, and a detachable mounting column 110. The rake teeth 120 at the front end and the drive shaft 130 driven by the geared motor installed in the inner cavity of the rake head cover 10 also include:

[0051] The first transmission box 20 is equidistantly distributed on the outer wall of the drive shaft 130, and the transmission end of the first transmission box 20 is connected with a transmission rod 210;

[0052] The first buffer part 30 is arranged in the middle section of the transmission rod 210. In this embodiment, the first buffer part 30 divides the transmission rod 210 into two sections, specifically a telescopic rod and a sleeve con...

Embodiment 2

[0068] The scheme in embodiment 1 is further introduced below in combination with specific working methods, see the following description for details:

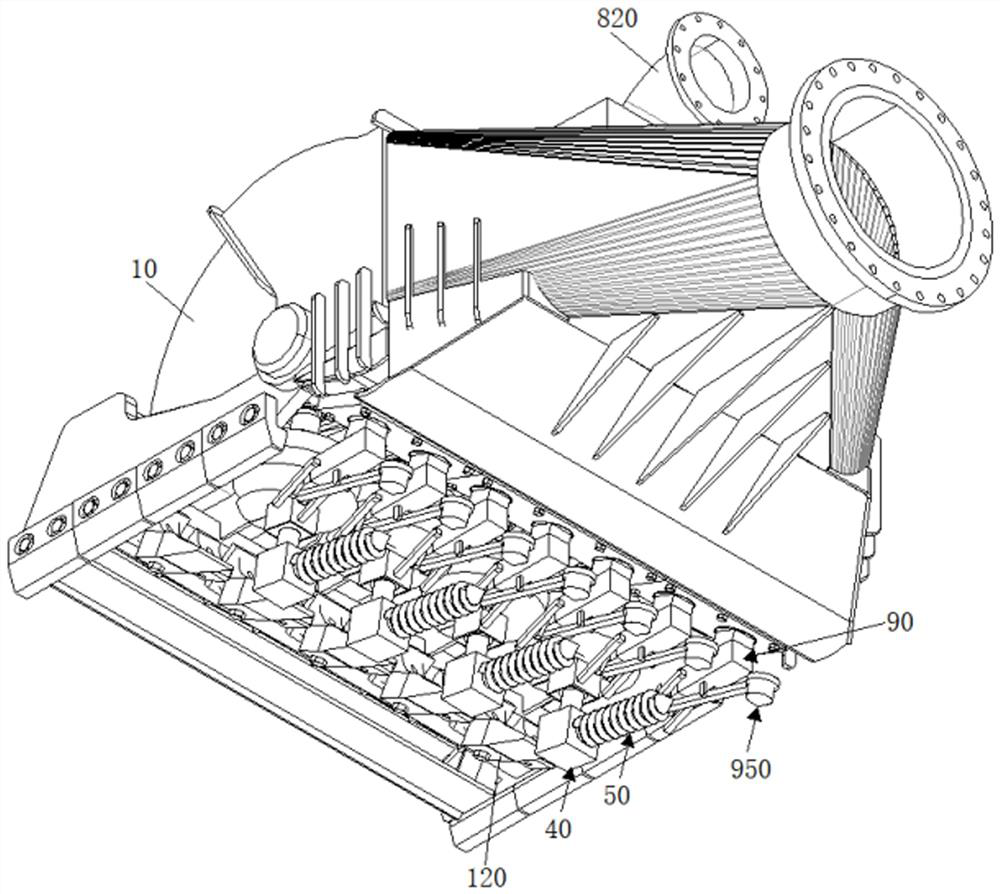

[0069] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 9 and Figure 10 As shown, as a preferred embodiment, on the basis of the above method, further, the high-pressure water supply assembly 80 includes a water tank 810 installed in the rake head cover 10 and a water tank 810 installed on the top of the rake head cover 10 and communicated with the water inlet of the water tank 810 The high pressure flushing water pipeline 820.

[0070] The intermittent spray assembly 90 includes a sleeve 910 connected to the water outlet of the water tank 810, a sleeve rod 920 slidingly connected with the sleeve 910, a compression spring 930 sleeved on the sleeve rod 920 and placed in the rod section of the inner chamber of the sleeve 910, and set in the sleeve The pressure relief port on the outer wall of 910, the spray p...

Embodiment 3

[0073] The scheme in embodiment 2 is further introduced below in conjunction with specific working methods, see the following description for details:

[0074] Such as Figure 9 , Figure 10 As shown, as a preferred embodiment, on the basis of the above method, further, the intermittent hammer assembly 950 includes a connecting rod 951 fixedly connected to the outer wall of the sleeve 910, and a hammer connected to the end of the sleeve rod 920 away from the sleeve 910 in rotation. The hammer shaft 952 and the hammer head 953 installed on the end of the hammer shaft 952 away from the sleeve rod 920, the end of the connecting rod 951 away from the sleeve 910 is movably connected with the middle section of the hammer shaft 952;

[0075] When in use: through intermittent reciprocating expansion and contraction of the sleeve rod 920 on the intermittent injection assembly 90, the reciprocating swing of the hammer shaft 952 is realized, and then the intermittent hammering of the ha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com