Building hoisting equipment one-machine one-gear management platform, construction method and use method

A technology of lifting equipment and management platform, which is applied in file system management, file management system, neural learning method, etc. It can solve the problems of data omission and lack, company manpower, material resources, financial resources loss, long time and other problems, so as to achieve convenient search and arrangement , Easy to manage equipment data, send and collect simple effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

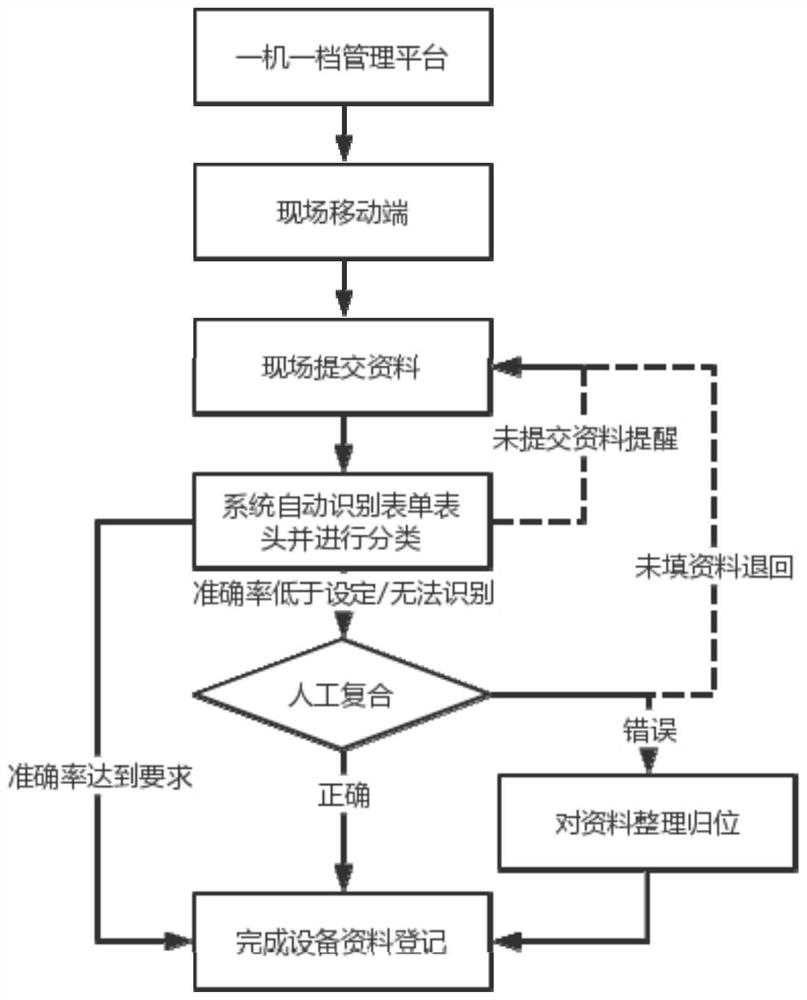

[0041] Example 1: Please refer to Figure 4 , when registering equipment installation data during actual use, the following steps are included:

[0042] In the first step, the on-site management personnel upload the equipment installation information to the management terminal through the mobile terminal, including the installation notification form, the basic acceptance form, the entry inspection form, the pre-installation checklist, the safety technology disclosure document, the installation monitoring technical form, and the installation plan And the emergency plan, the management terminal judges the uploaded equipment installation information, and judges whether the information is complete. If it is complete, it will proceed to the next step. Let the on-site management staff re-submit;

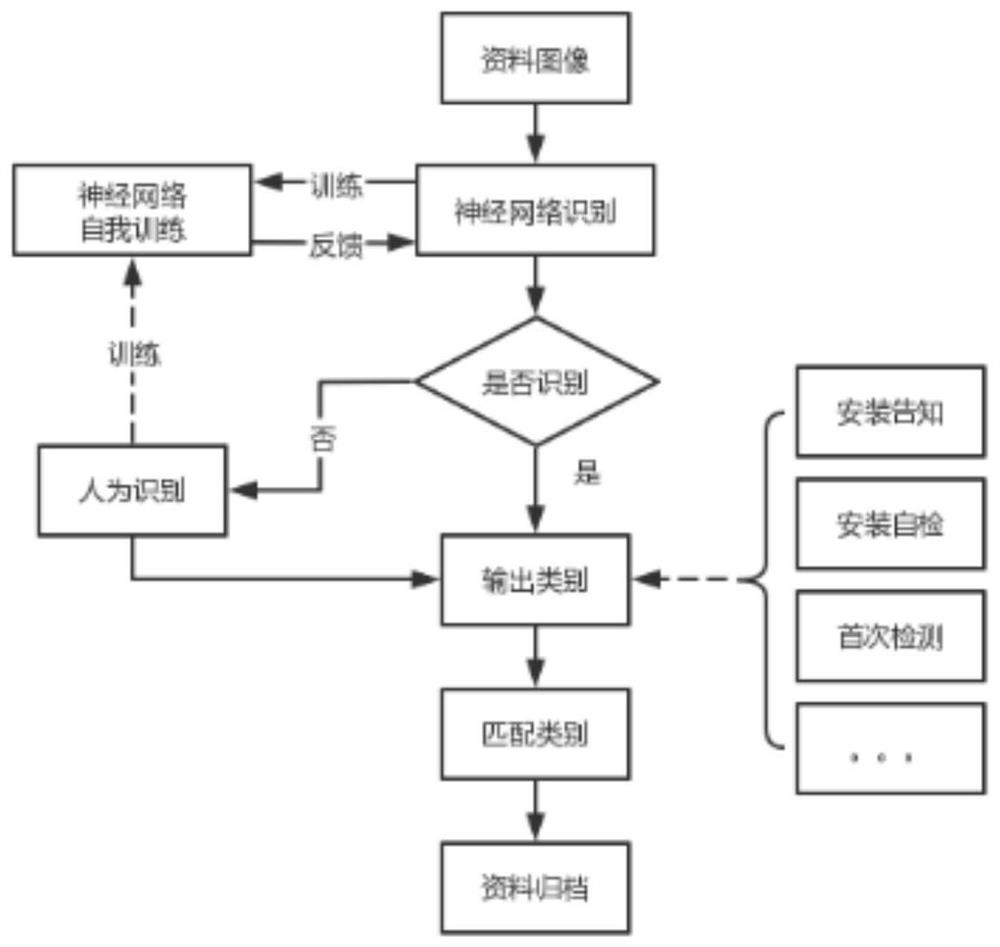

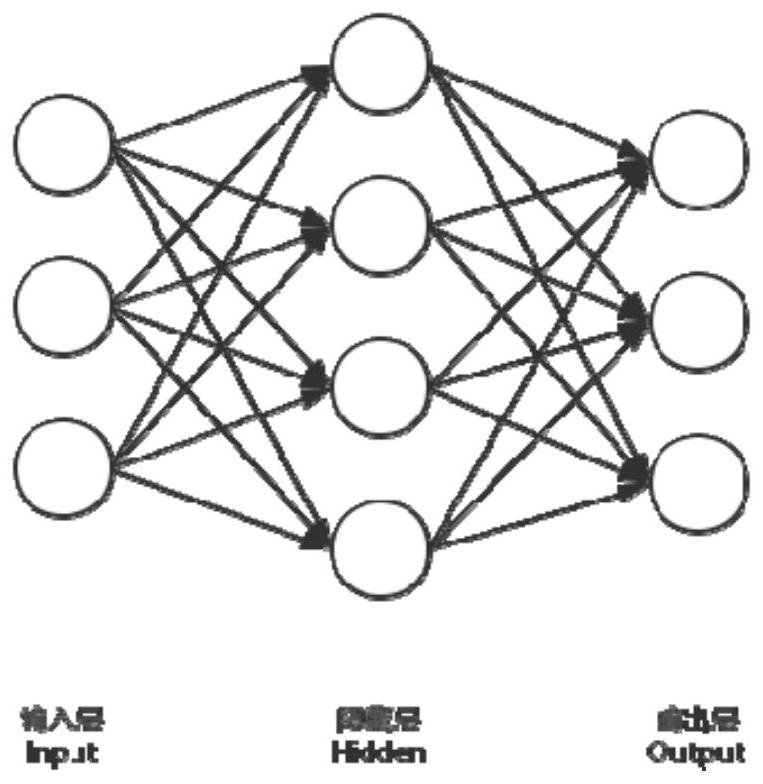

[0043] In the second step, the management terminal performs image recognition on the uploaded equipment installation data information, and judges the type of equipment data information by...

Embodiment 2

[0045] Example 2: Please refer to Figure 5 , when registering equipment self-inspection data during actual use, the following steps are included:

[0046] In the first step, the on-site management personnel upload the equipment self-inspection data information to the management terminal through the mobile terminal, including the installation self-inspection form, and the management terminal judges the uploaded equipment self-inspection data information to determine whether the information is complete. , proceed to the next step, if it is incomplete, the management terminal will send a reminder of the unsubmitted materials to the mobile terminal, so that the on-site management personnel can re-submit;

[0047] In the second step, the management terminal performs image recognition on the uploaded device self-inspection data information, and judges the type of device data information by identifying the header, and evaluates it according to the accuracy rate after recognition. If...

Embodiment 3

[0049] Example 3: Please refer to Image 6 , when the device registers the (first) test data of the device during actual use, the following steps are included:

[0050] In the first step, the on-site management personnel upload the equipment (first) inspection data information to the management terminal through the mobile terminal, including the first installation inspection report / regular inspection report, and the management terminal judges the uploaded equipment (first) inspection data information and judges the data Whether the information is complete, if complete, proceed to the next step, if not complete, the management terminal will send a reminder of the unsubmitted materials to the mobile terminal, so that the on-site management personnel can re-submit;

[0051] In the second step, the management terminal performs image recognition on the uploaded device (first) detection data information, and judges the type of device data information by identifying the header, and e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com