Novel high-molecular polymer cable

A high molecular polymer, cable technology, applied in the direction of insulated cables, power cables with shielding/conductive layers, cables, etc., can solve the problems of limited mechanical and anti-vibration performance of cables, achieve good mechanical strength and avoid slippage Wear and longevity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In order to explain in detail the technical content, structural features, achieved goals and effects of the technical solution, the following will be described in detail in conjunction with specific embodiments and accompanying drawings.

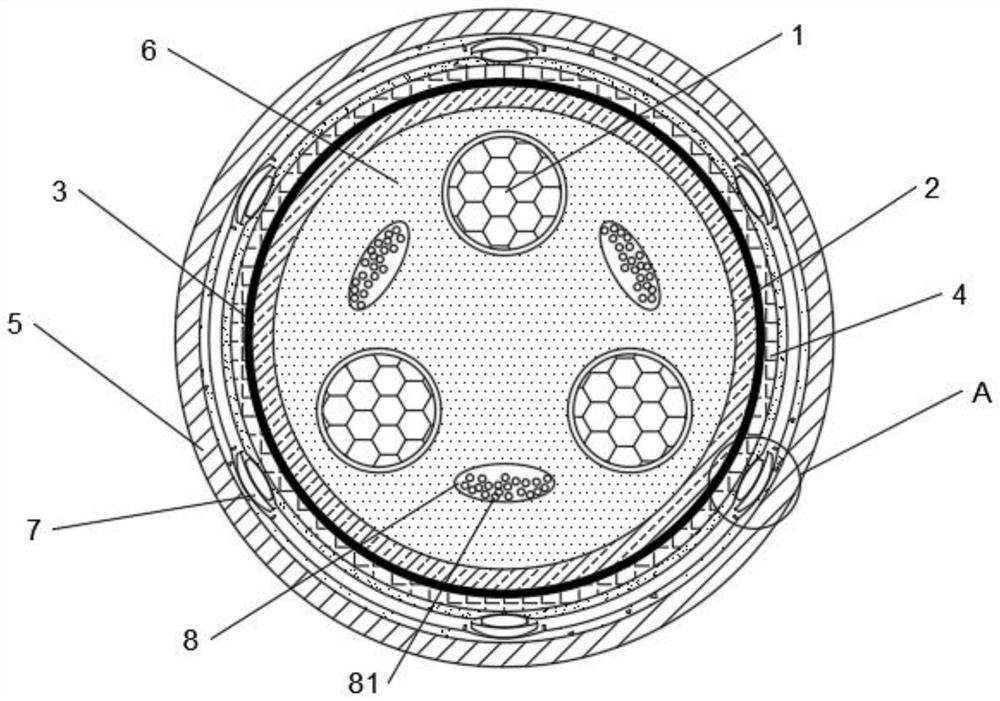

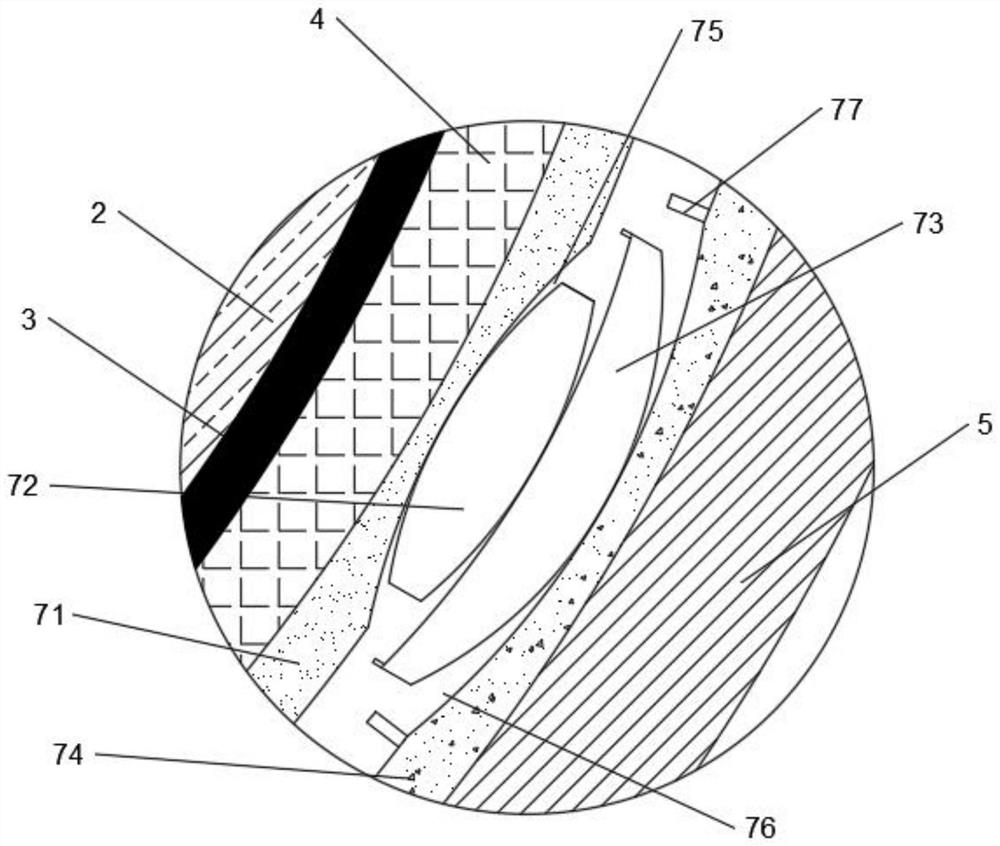

[0025] see Figure 1-2 , this embodiment provides a new polymer cable, including three cable cores 1, inner sheath 2, metal shielding layer 3, flame retardant layer 4 and outer sheath 5, cable core 1 and outer sheath There are six friction damping devices 7 in the circumferential direction between the 5, an inorganic mineral layer 6 is distributed between the cable core 1 and the inner sheath 2, and the materials of the inner sheath 2 and the outer sheath 5 are nano-doped modified polypropylene material.

[0026] In this embodiment, the nano-doped modified polypropylene material is subjected to the following tests according to the difference of each raw material component:

[0027] Trial 1: 80 parts polypropylene, 30 parts SEBS elas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com