Intelligent crimping device for strain clamp

A technology of crimping device and tension clamp, which is applied in the direction of connection, line/collector parts, electrical components, etc., can solve the problem of poor bending degree of crimping of strain-resistant wires, long crimping guide rail length, and restrictions on aerial work platforms And crimping machine weight and other issues, to improve the quality of crimping, improve the effect of straightness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] In order to better understand the present invention, the content of the present invention will be further described below in conjunction with the accompanying drawings and examples.

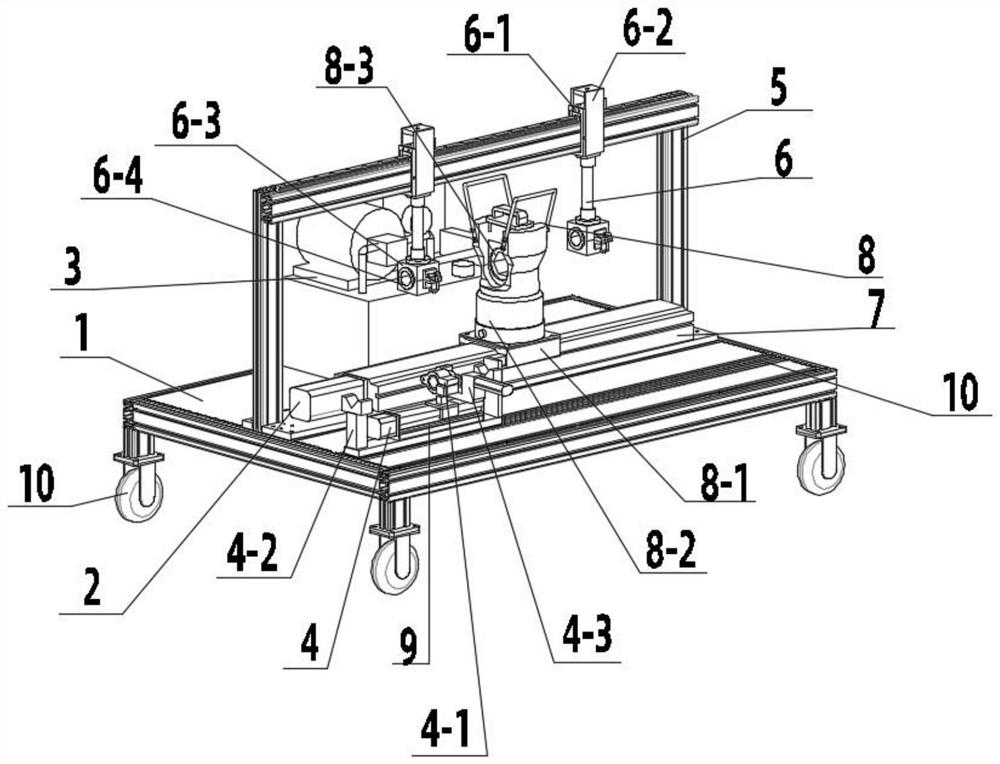

[0027] As shown in the figure, the present invention provides an intelligent crimping device for strain clamps, including a working platform 1, a crimping device 2 arranged in the middle of the working platform 1, and two crimping devices respectively arranged on the crimping device 2. side hydraulic pump 3 and cutting device 4;

[0028] The crimping device 2 includes a gantry bracket 5, two suspension clamping devices 6 that are slidably arranged on the top of the gantry bracket 5, a rolling screw slide rail device I7 that is arranged directly below the gantry bracket 5, and is arranged on the rolling screw The crimping pliers 8 on the slide rail device I7, the suspension clamping device 6 includes a sliding sleeve 6-1 sleeved on the gantry bracket 5, an adjustable connecting plate 6-2 ar...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap