Packaged adhesive unit

A technology of adhesives, bituminous binders, applied in the field of manufacturing bituminous compositions, capable of solving problems such as drops, changes in adhesive properties, costly safety procedures, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example

[0097] The present invention will now be described by reference to examples, which are not intended to limit the invention.

example 1

[0099] Load tests were carried out on adhesive units of packages containing 95 to 105 g of adhesive comprising a double layer of sealable laminating adhesive according to the present invention in order to compare their properties with those comprising Adhesive units of other packages of casings not made of the material according to the invention were compared.

[0100] Other shells made of materials not according to the invention are LDPE only, LDPE / HDPE laminates, LLDPE / HDPE laminates, BOPP only and CPP only.

[0101] Adhesive units of packages comprising BOPP only, CPP only, BOPP / CPP and BOPET / LDPE were subjected to a 7 day load test at 60°C under a load of 2T. However, for adhesive units of packages containing LDPE only, LDPE / HDPE laminates and LLDPE / HDPE laminates, shorter cycles were applied at lower temperatures and less loads, as shown in Table 1, to determine their integrity limitations as these materials are not as strong as BOPP / CPP and BOPET / LDPE.

[0102] The res...

example 2

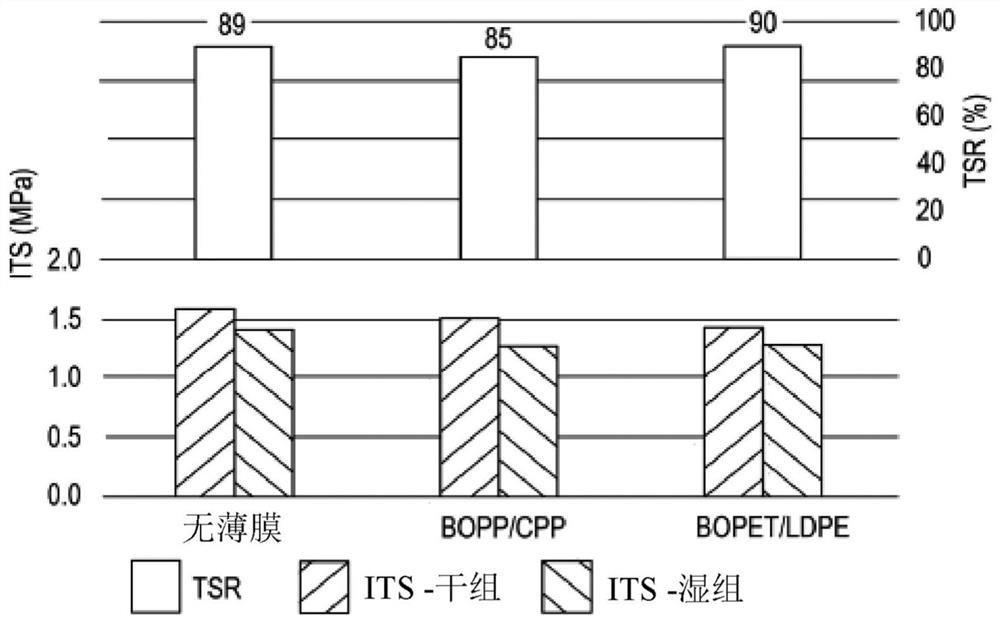

[0107] Bituminous compositions were evaluated for resistance to water damage according to standard test AASHTO T283 to determine how the presence of a sealable laminated double layer in the bituminous composition affects the performance of the bituminous composition.

[0108] image 3 The results presented in show that the stiffness of bituminous mixtures and the effect of moisture on stiffness are similar for adhesives with and without sealable lamination bilayers (BOPP-CPP and BOPET-LDPE).

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com