Filter for transfer printing ink

A filter and ink technology, applied in the field of filters, can solve the problems of easy liquid splashing to the surrounding, difficult separation, inconvenient cleaning, etc., and achieve the effects of simple disassembly and installation steps, reduced liquid area, and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

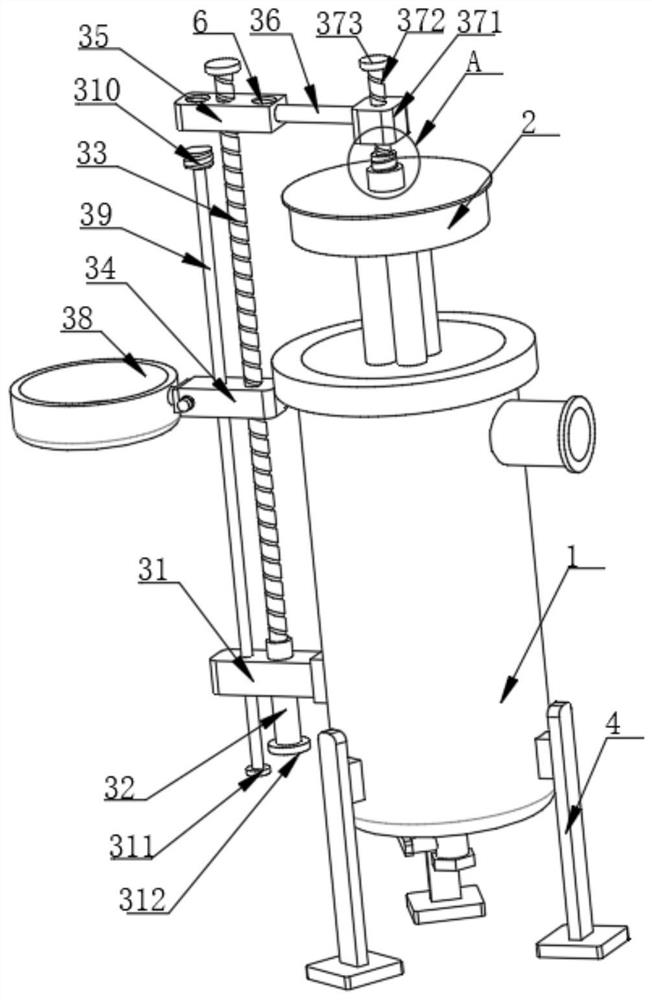

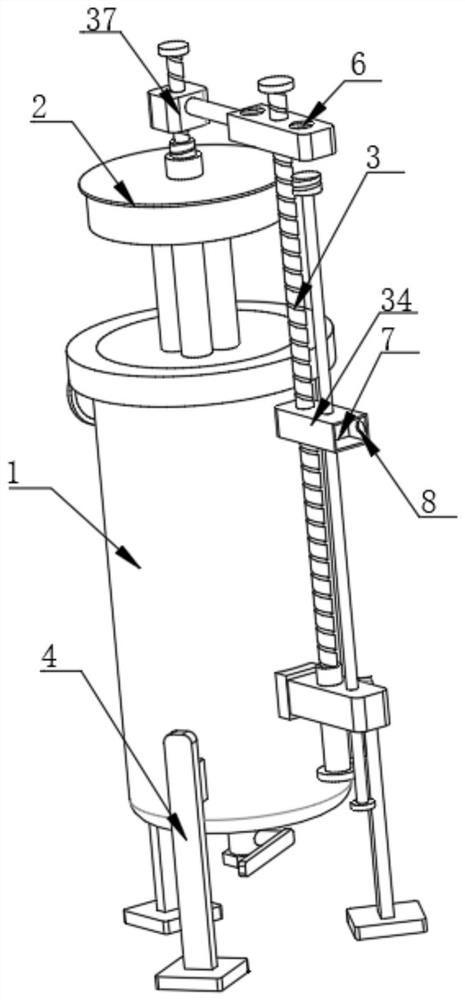

[0039] In one embodiment, see Figure 1-5, the present invention provides a technical solution: a filter for transfer ink, comprising a body 1 and a cover body 2, one side of the body 1 is provided with a cover leak-proof device 3, by setting the cover leak-proof device 3, so that the cover body 2 can be supported and removed under the drive of the first thread rod 33, and can prevent the cover body 2 from dripping liquid during the removal process to the ground, the bottom of the body 1 is fixed connected with three support rods 4, the top of the cover body 2 is fixed connected to the threaded cylinder 5, by setting the threaded barrel 5, Such that the cover body 2 may be fixed with the fixed structure 37 fixed.

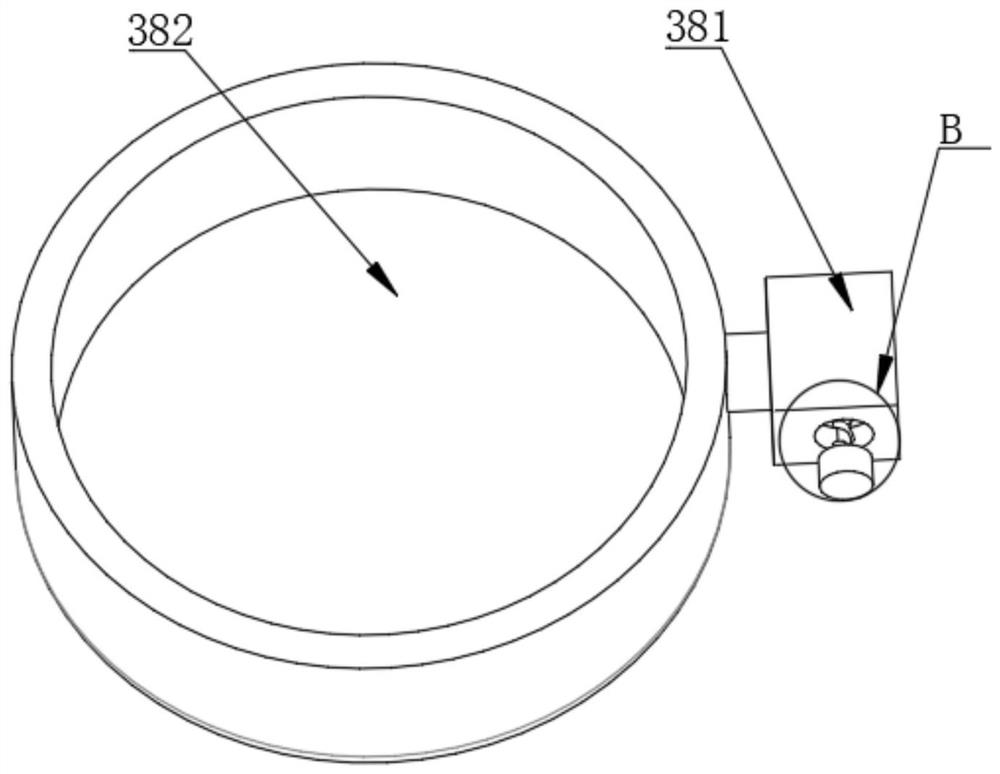

[0040] Cover leak-proof device 3 includes a mounting block 31, the mounting block 31 is fixedly connected to the outer surface side of the fuselage 1, the inner wall of the mounting block 31 is connected to the rotating rod 32 by bearing rotation, the top of the rotati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com