Polyester fiber stirring device

A stirring device and polyester fiber technology, applied in the direction of transportation and packaging, mixers, dissolution, etc., can solve the problems of turbulent flow, can not better improve the mixing effect of raw materials and additives, and achieve the effect of improving the dispersion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

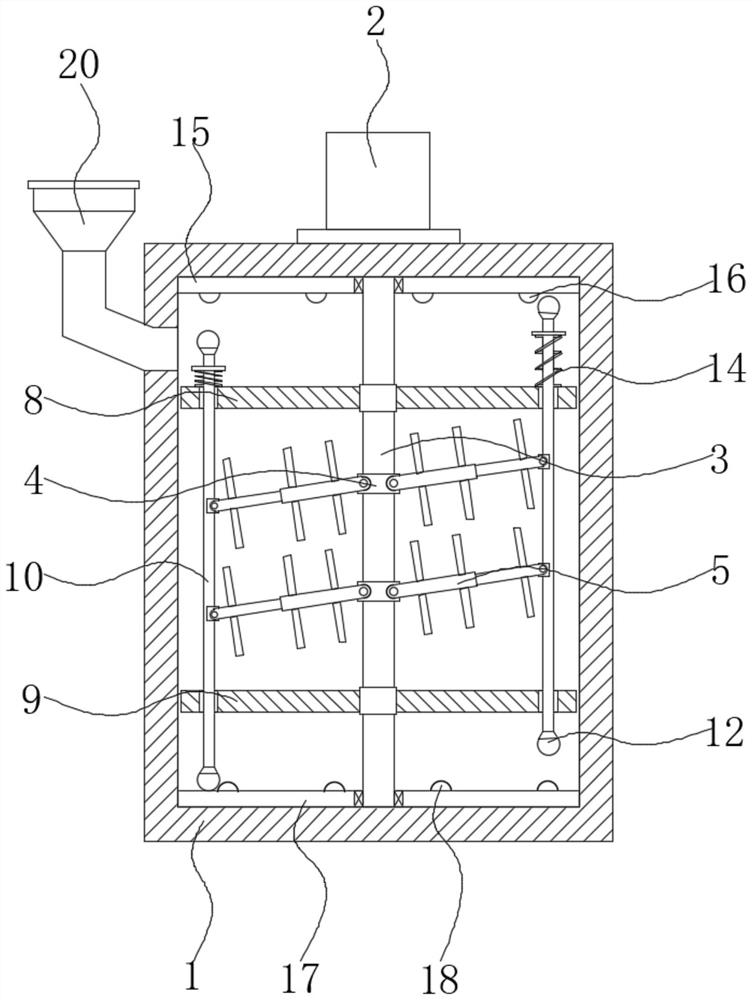

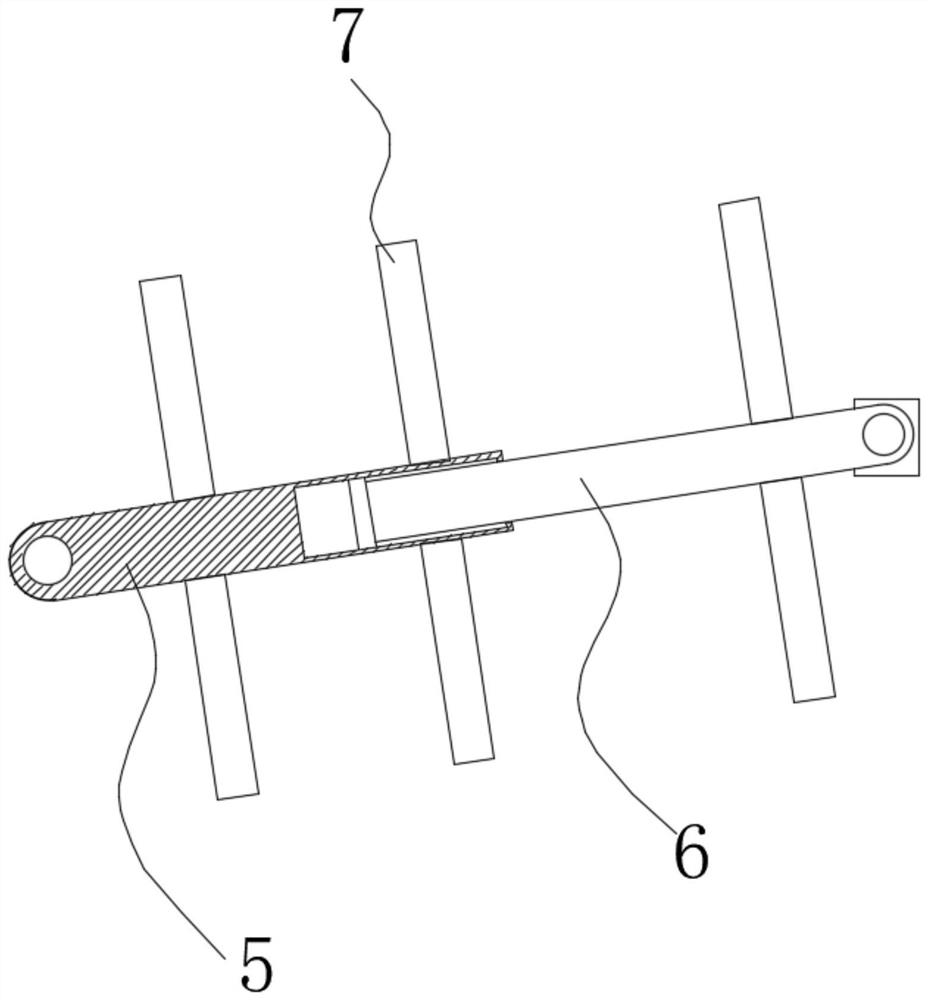

[0022] Example: see Figure 1-5 , used for polyester fiber stirring device, including a fermenter 1, the top of the fermenter 1 is provided with a stirring motor 2, the driving end of the stirring motor 2 is provided with a stirring shaft 3, the outside of the stirring shaft 3 is provided with a mounting shell 4, and the mounting shell 4. Both ends of the exterior are hinged with a first stirring rod 5, and the inner side of the first stirring rod 5 away from the installation shell 4 is slidingly sleeved with a second stirring rod 6, and the outside of the top of the stirring shaft 3 is provided with a first cross bar 8, The outside of the bottom end of the stirring shaft 3 is provided with a second cross bar 9, and both ends of the first cross bar 8 are provided with a push rod 10, the top of the push rod 10 is provided with a first magnetic block 11, and the bottom of the push rod 10 is provided with a The second magnetic block 12, the outside of the push rod 10 top is provi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com