Polarizing film tearing mechanism

A polarizing film and film machine technology, applied in lamination, chemical instruments and methods, lamination auxiliary operations, etc., can solve the problems of low efficiency of manual film tearing, film residue on the polarizer, and uneven force of manual manual film tearing, etc. , to achieve the effect of improving efficiency and uniform force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

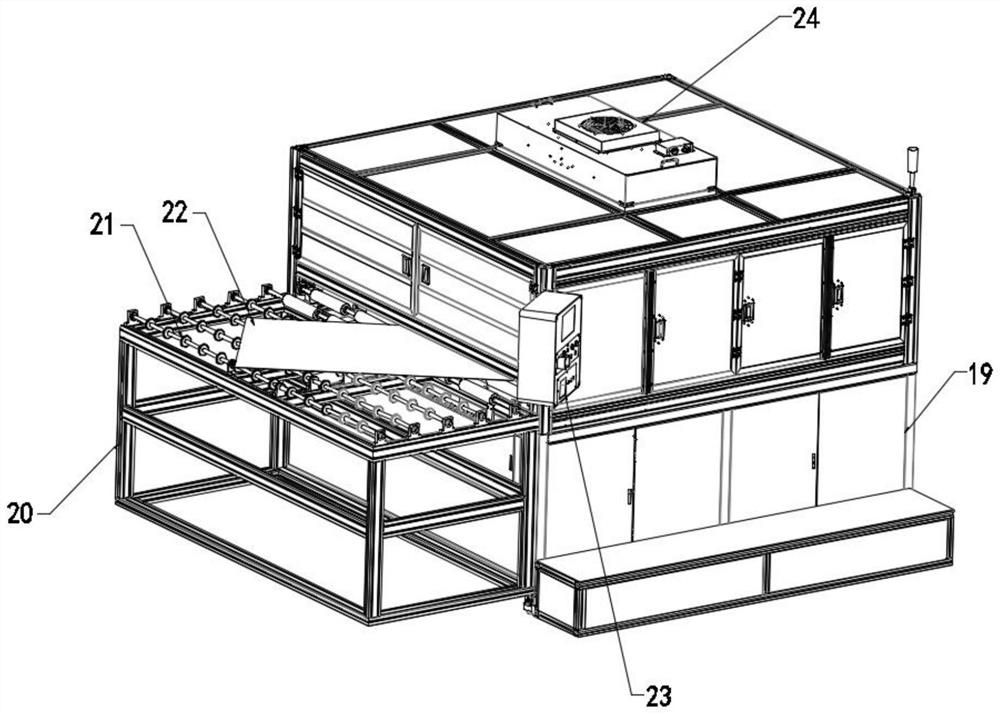

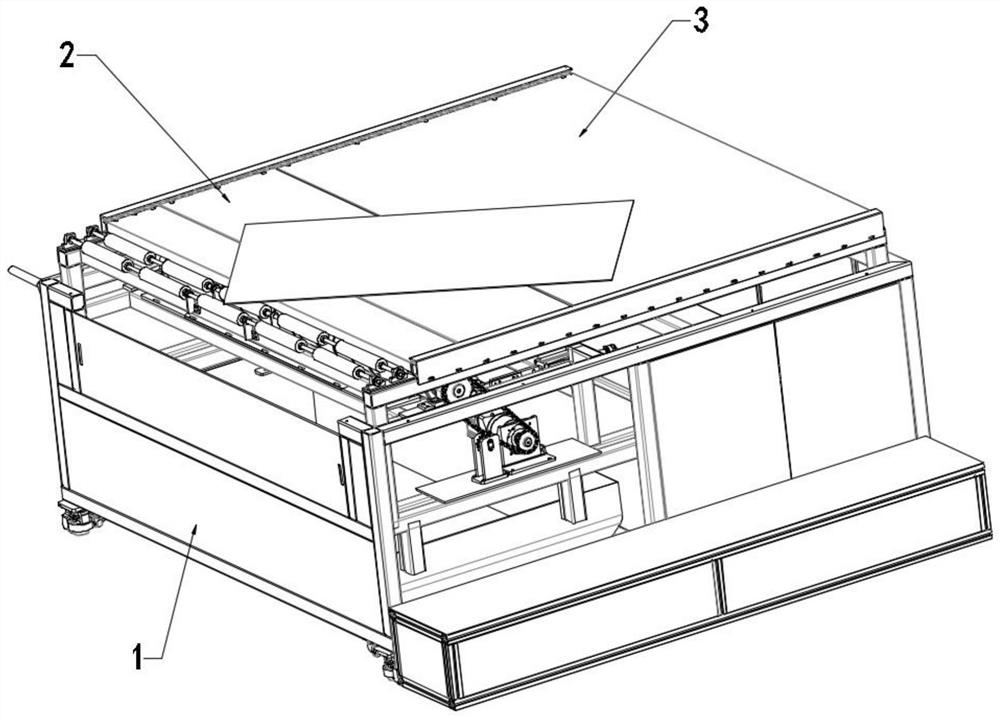

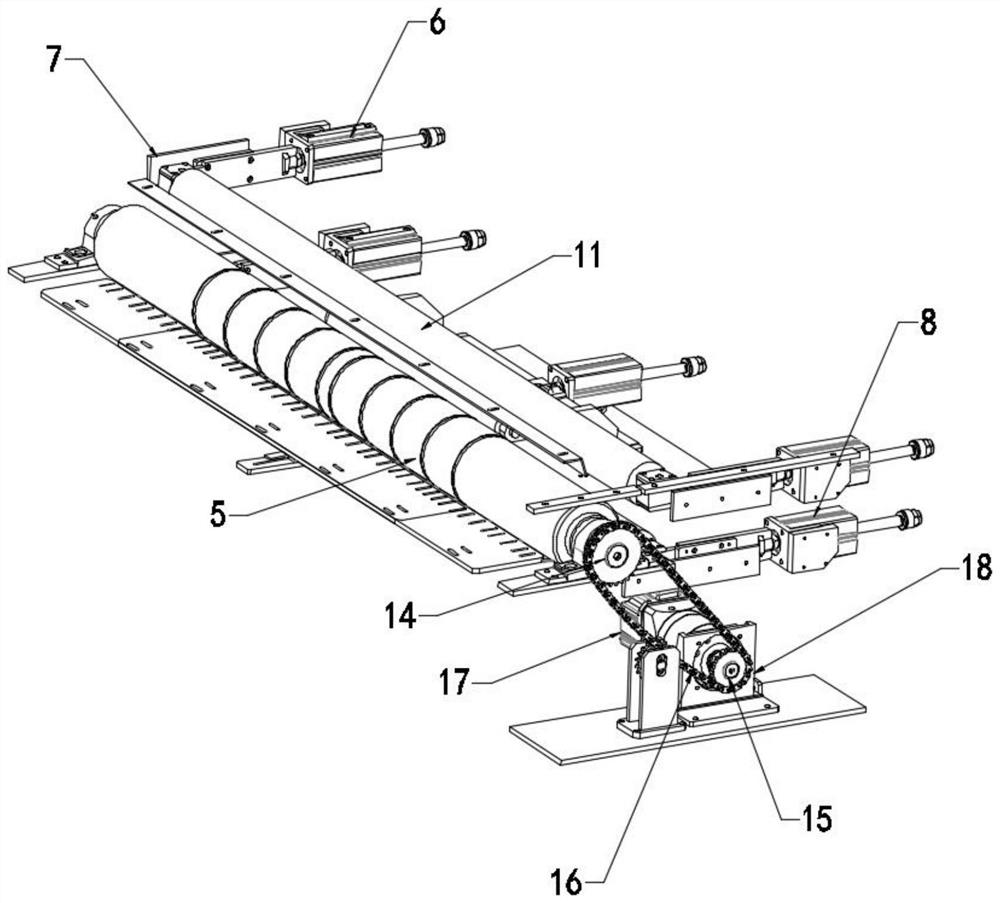

[0034] see Figure 1-6 , the present invention provides a technical solution: a polarizing film tearing mechanism, including a tearing film frame 1, a first fixing plate 2 and a second fixing plate 3 are fixedly installed on the tearing film frame 1, the first fixing plate 2 There is a gap between the second fixed plate 3, the bottom of the first fixed plate 2 is fixedly equipped with a baffle plate 4, the film tearing frame 1 is rotated and installed with a rubberized roller 5, and the tearing film frame 1 is fixedly installed with a first Cylinder 6, the first moving frame 7 is fixedly installed on the piston rod of the first cylinder 6, the first roller shaft 11 is installed on the first moving frame 7, and the film tearing frame 1 is provided with a drive to rotate the rubber drum 5. Drive mechanism.

[0035] The drive mechanism includes a drive motor 17, a mounting base 18 is fixedly installed on the film tearing frame 1, a driving motor 17 is fixedly installed on the mo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com