Three-gear hub driving device and using method thereof

A technology of driving device and blocking wheel, applied in power device, control device, motion deposition and other directions, can solve the problems of small torque variation range, slow wheel dynamic response speed, poor economy, etc., to achieve fast response, improve dynamic balance, compact effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

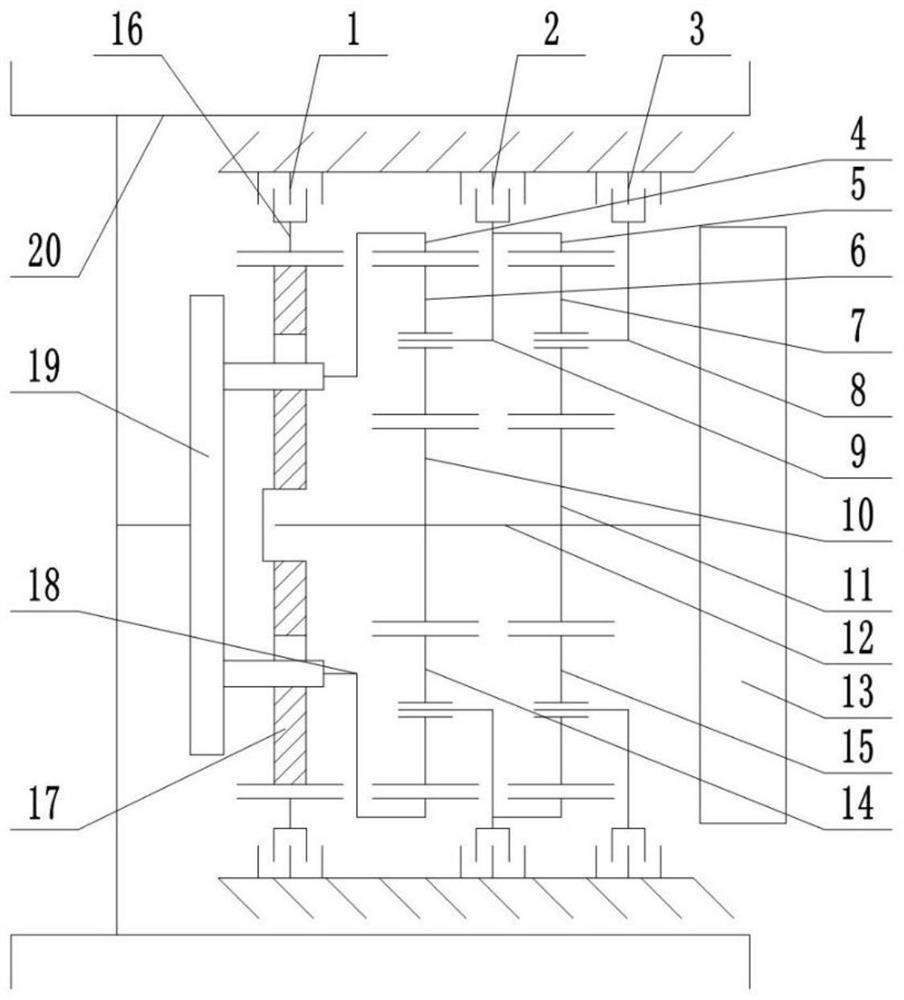

[0061] Such as Figure 1-4 As shown, the first transmission part includes the first sun gear 11, the first planet carrier 8, the first planetary gear 7, the fourth planetary gear 15 and the first ring gear 5, and the first ring gear 5 is provided with a chuck 25 The matching first notch; the first sun gear 11 is connected with the transmission shaft 12, the fourth planetary gear 15 is connected with the first sun gear 11, the first planetary gear 7 is connected with the first ring gear 5, and the first planetary gear 7 and the fourth planetary gear 15 are connected with the first brake 3 through the first planet carrier 8, and the second brake 2 is connected with the first ring gear 5;

[0062] The second transmission assembly includes the second sun gear 10, the second planet carrier 9, the second planetary gear 6, the third planetary gear 14 and the second ring gear 4, and the second ring gear 4 is provided with a The second notch; the second sun gear 10 is connected with t...

specific Embodiment approach

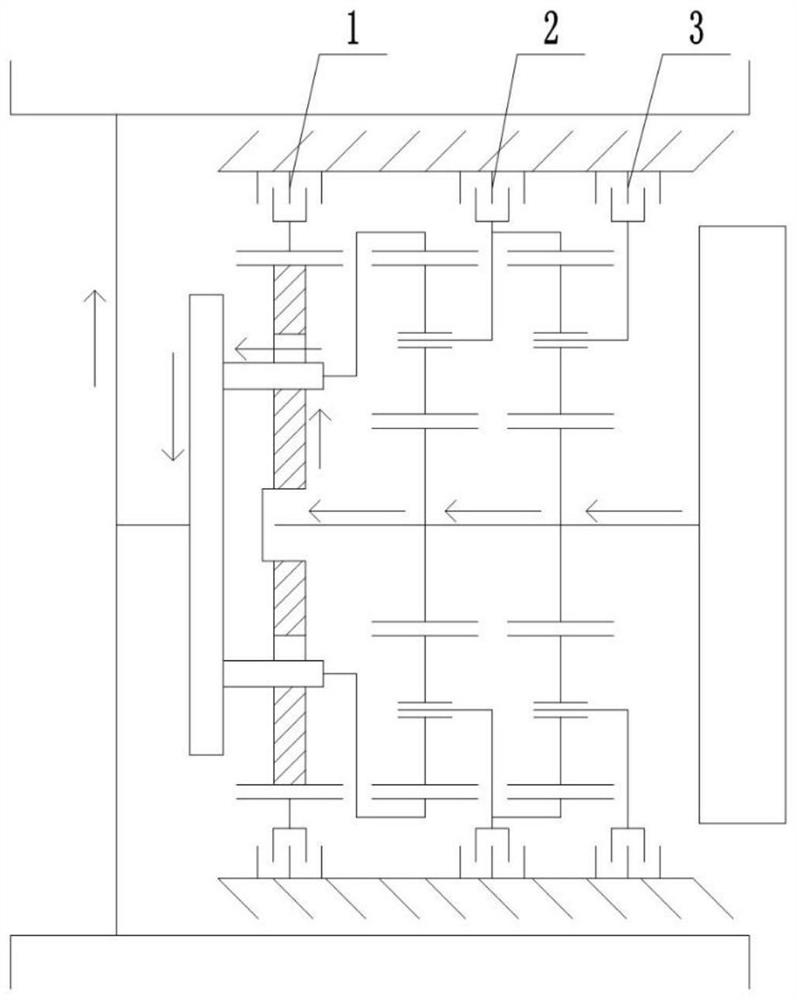

[0064] When the vehicle is in the braking state, the shift motor 21 works, and the chuck 25 close to the shift motor 21 is driven to match the third notch on the third ring gear 16. Reverse self-locking function, and the third brake 1 works, the third ring gear 16 stops rotating, and the vehicle shifts into the first gear; the power is transmitted to the transmission shaft 12 through the motor 13, and the transmission shaft 12 electric eccentric planetary gear 17 works, and the eccentric planetary gear 17 drives the gear sleeve 19 to work, and the gear sleeve 19 drives the wheel hub 20 to output power;

[0065] When the vehicle is in the braking state, the shift motor 21 works for the second time, driving the chuck 25 in the middle to match the second notch on the second ring gear 4, and when the wheel rotates, the worm gear 22 and the worm screw 23 are used to drive the reverse Self-locking function, and the second brake 2 works, the second ring gear 4 stops rotating, and the...

Embodiment 2

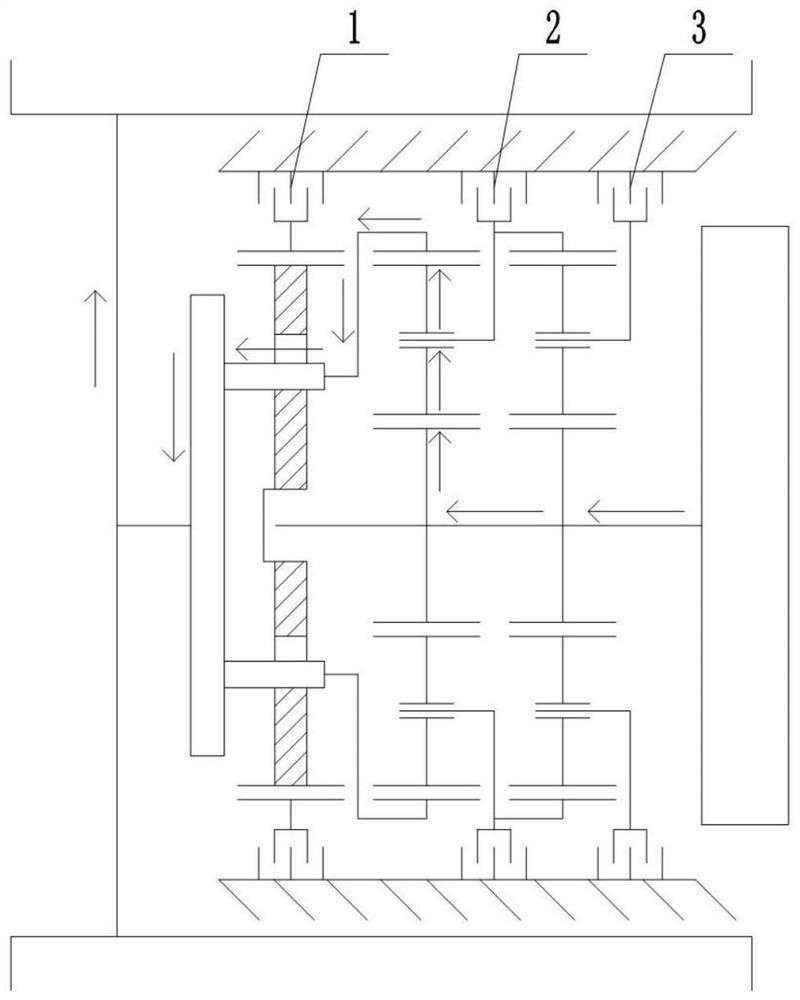

[0071] Such as Figure 5-8 As shown, the difference between the second embodiment and the first embodiment is that the first transmission assembly includes the first sun gear 11, the first planet carrier 8, the first planetary gear 7, the fourth planetary gear 15 and the first ring gear 5, and the first A ring gear 5 is provided with a first notch compatible with the chuck 25; the first sun gear 11 is connected with the transmission shaft 12, the fourth planetary gear 15 is connected with the first sun gear 11, and the first planetary gear 7 is connected with the first sun gear 11. The first ring gear 5 is connected, the fourth planetary gear 15 and the first planetary gear 7 are connected with the second brake 2 through the first planet carrier 8, and the first ring gear 5 is connected with the first brake 3;

[0072] The second transmission assembly includes the second sun gear 10, the second planet carrier 9, the second planetary gear 6, the third planetary gear 14 and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com