Method for improving yield of alpha-olefin in ethylene oligomerization reaction

An olefin yield, ethylene oligomerization technology, applied in chemical instruments and methods, hydrocarbons, hydrocarbons, etc., can solve the problems of increasing separation costs, affecting product quality, etc., achieving good economic benefits, improving reactivity, Easy to achieve effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

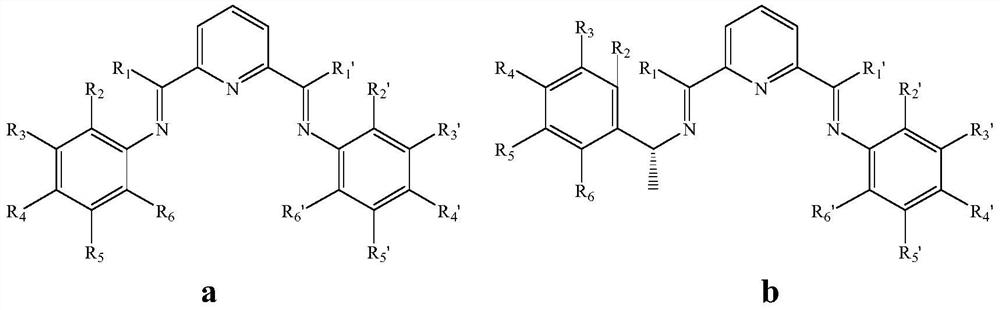

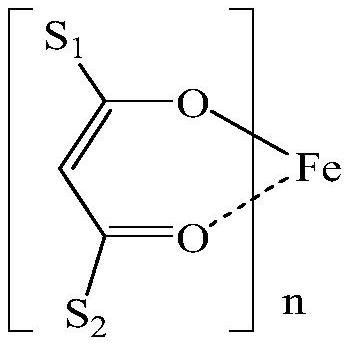

[0047] Under nitrogen protection, the bis-imine pyridine ligand L{2,6-bis-[(2-methylanilinoethyl)pyridine]} shown in formula a is molar ratio 1 with ferrous chloride: After compounding of 1, a catalyst represented by formula a' is obtained. dubbed 4×10 -6 mol / mL of the main catalyst toluene suspension. The cocatalyst methylaluminoxane (MAO) is a 10 wt% toluene solution, and the concentration of the substance is about 1.5 mol / L.

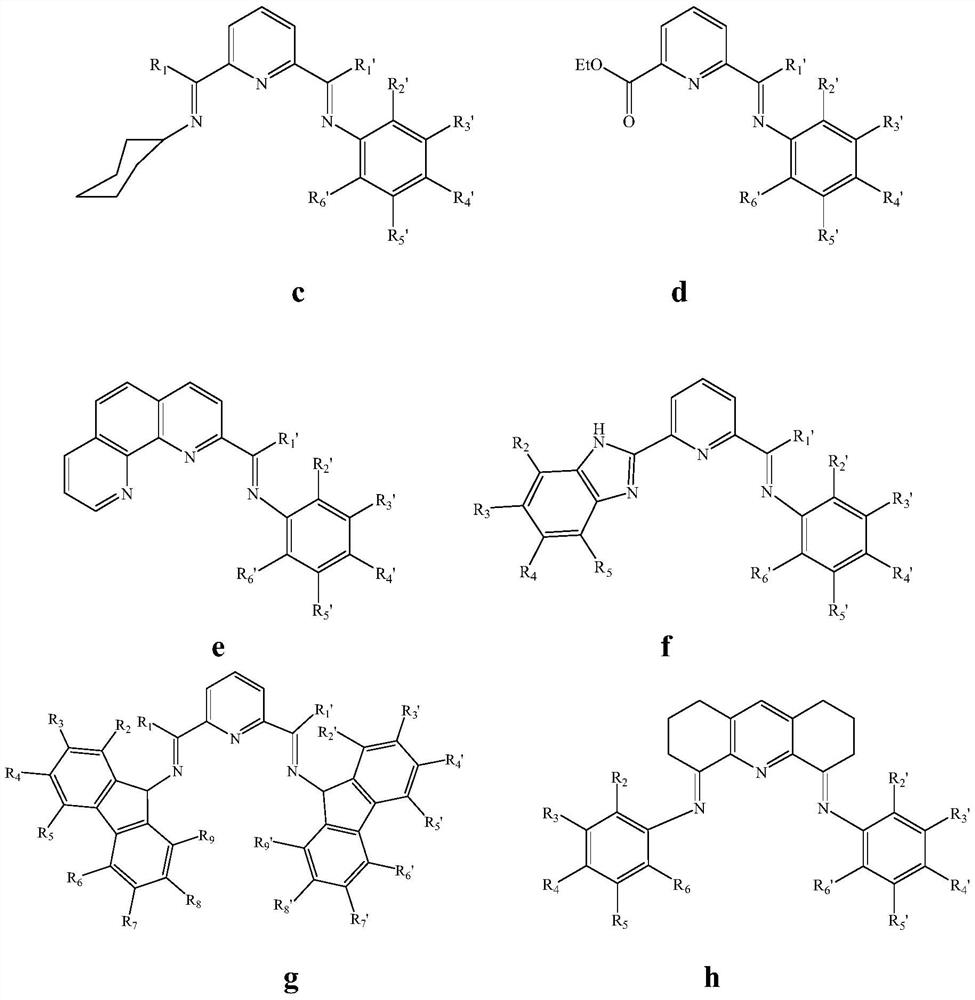

[0048] Catalyst LFeCl 2 The structural formula:

[0049]

[0050] Heat the 250ml oligomerization reactor to above 90°C, vacuum bake for 2 hours, and replace it with high-purity nitrogen several times during this period. Subsequently, the temperature of the reactor was adjusted to a reaction temperature of 50° C. by circulating jacketed cooling water, and 50 mL of toluene was added as a reaction medium. Add cocatalyst MAO (denoted as Al MAO ) and activity modulator AlCl 3 , and stirred for 30 minutes. Subsequently, open the ethylene pressure...

Embodiment 2

[0053] Activity modulator is AlCl 3 , [AlCl 3 ]:[Al MAO ]=0.04, other operations are the same as embodiment 1. The reaction product was separated to obtain linear α-olefin, which was analyzed by gas chromatography to obtain 2.43g; K=0.73; the activity was 2430kg·(mol-Fe·h) -1 .

Embodiment 3

[0055] Activity modulator is AlCl 3 , [AlCl 3 ]:[Al MAO ]=0.08, other operations are the same as embodiment 1. The reaction product was separated to obtain linear α-olefin, which was analyzed by gas chromatography to obtain 3.57g; K=0.70; the activity was 3570kg·(mol-Fe·h) -1 .

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap