Polishing abrasive and production and preparation process thereof

A technology of polishing grinding and formaldehyde resin, which is applied in the direction of polishing compositions containing abrasives, other chemical processes, chemical instruments and methods, etc., can solve problems such as inconvenient production and preparation, high use limitations, and inconvenient adjustments, and achieve The surface is delicate, improving the effect of polishing and avoiding the treatment process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

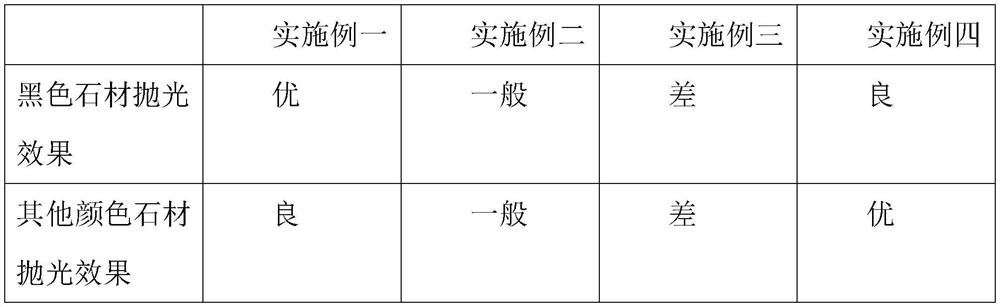

Examples

Embodiment 1

[0033] A kind of polishing abrasive, is made up of following percentage by weight:

[0034] p-tert-butylphenol formaldehyde resin: 3-5%;

[0035] Polyvinyl butyral: 2-4%;

[0036] Urea-formaldehyde modified melamine varnish powder: 25-30%;

[0037] Polysulfone resin: 5-10%;

[0038] Polyoxymethylene: 10-15%;

[0039] Graphite powder: 1-2%;

[0040] Diamond powder: 1-3%;

[0041] Polyurethane fluff powder: 1-3%;

[0042] Creamer: Make up to 100%.

[0043] The p-tert-butylphenol formaldehyde resin has good heat resistance, aging resistance and flexibility, and the mesh number of the p-tert-butylphenol formaldehyde resin is not less than 100 mesh.

[0044] Graphite powder has the effect of assisting lubrication and increasing heat-resistant glazing, and the mesh number of the graphite powder is not less than 300 mesh.

[0045] The particle size of the diamond micropowder is 0.5-1mm.

[0046] Polyurethane fluff powder is used instead of wool, so that the polished surface ...

Embodiment 2

[0059] A polishing abrasive, consisting of the following parts by weight:

[0060] p-tert-butylbenzene formaldehyde resin: 3-5%;

[0061] Polyvinyl butyral: 2-4%;

[0062] Urea-formaldehyde modified melamine varnish powder: 25-30%;

[0063] Polysulfone resin: 5-10%;

[0064] Polyoxymethylene: 10-15%;

[0065] Graphite powder: 1-2%;

[0066] Diamond powder: 1-3%;

[0067] Wool powder: 1-3%;

[0068] Creamer: Make up to 100%.

[0069] The p-tert-butylphenol formaldehyde resin has good heat resistance, aging resistance and flexibility, and the mesh number of the p-tert-butylphenol formaldehyde resin is not less than 100 mesh.

[0070] Graphite powder has the effect of assisting lubrication and increasing heat-resistant glazing, and the mesh number of the graphite powder is not less than 300 mesh.

[0071] The particle size of the diamond micropowder is 0.5-1 mm.

[0072] Urea-formaldehyde modified melamine varnish resin has high consolidation strength, good self-lubricat...

Embodiment 3

[0084] A kind of polishing abrasive, is made up of following percentage by weight:

[0085] p-tert-butylphenol formaldehyde resin: 3-5%;

[0086] Polyvinyl butyral: 2-4%;

[0087] Polysulfone resin: 5-10%;

[0088] Polyoxymethylene: 10-15%;

[0089] Graphite powder: 1-2%;

[0090] Diamond powder: 1-3%;

[0091] Polyurethane fluff powder: 1-3%;

[0092] Urea-formaldehyde modified melamine varnish powder: make up to 100%.

[0093] The p-tert-butylphenol formaldehyde resin has good heat resistance, aging resistance and flexibility, and the mesh number of the p-tert-butylphenol formaldehyde resin is not less than 100 mesh.

[0094] Graphite powder has the effect of assisting lubrication and increasing heat-resistant glazing, and the mesh number of the graphite powder is not less than 300 mesh.

[0095] The particle size of the diamond micropowder is 0.5-1mm.

[0096] Polyurethane fluff powder is used instead of wool, so that the polished surface is finer and more uniform i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com