Wet electrophotographic printer

A photography, wet electrography technology, applied in the direction of electrography, electric recording process applying charge pattern, equipment of electric recording process applying charge pattern, etc. Absorption etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

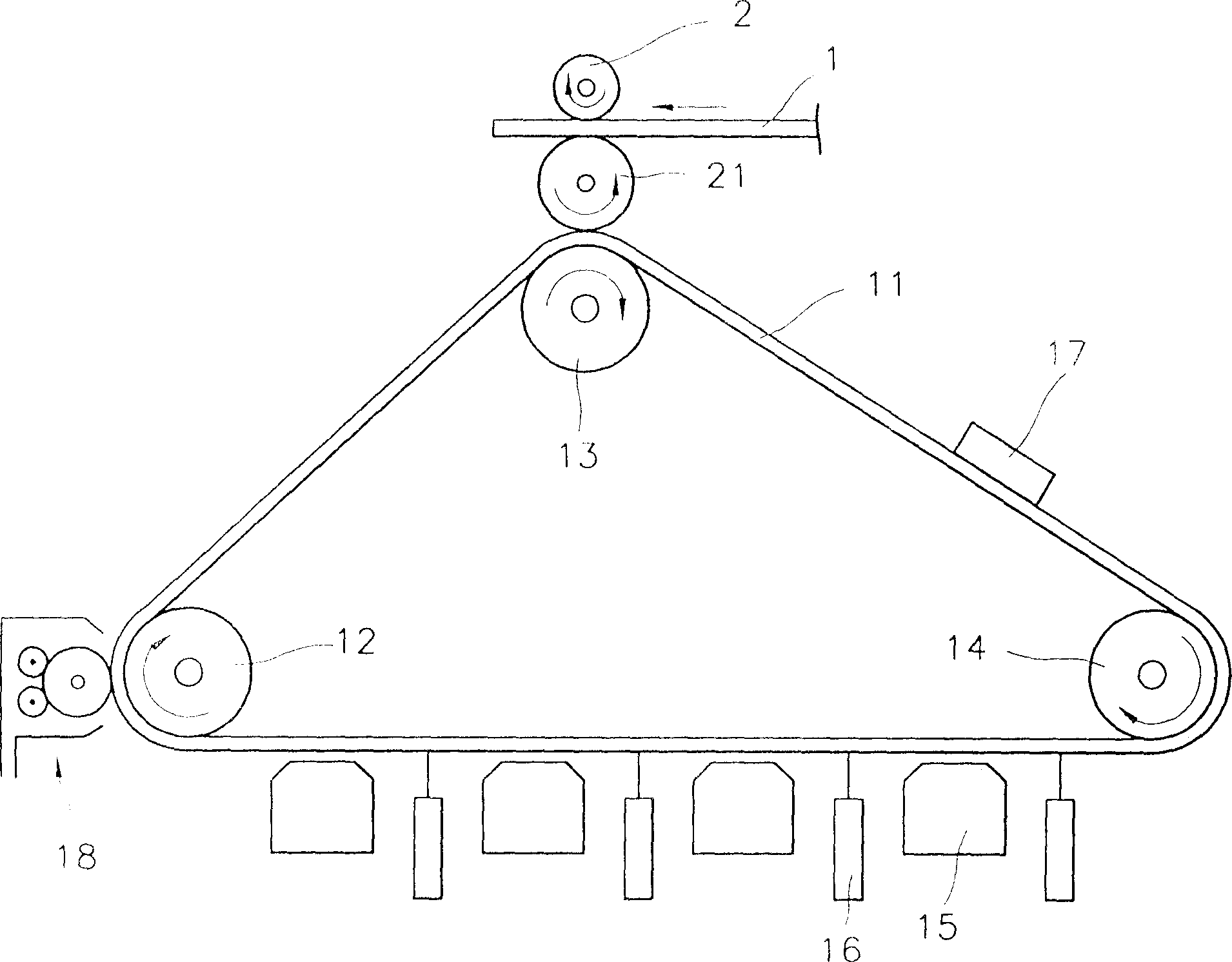

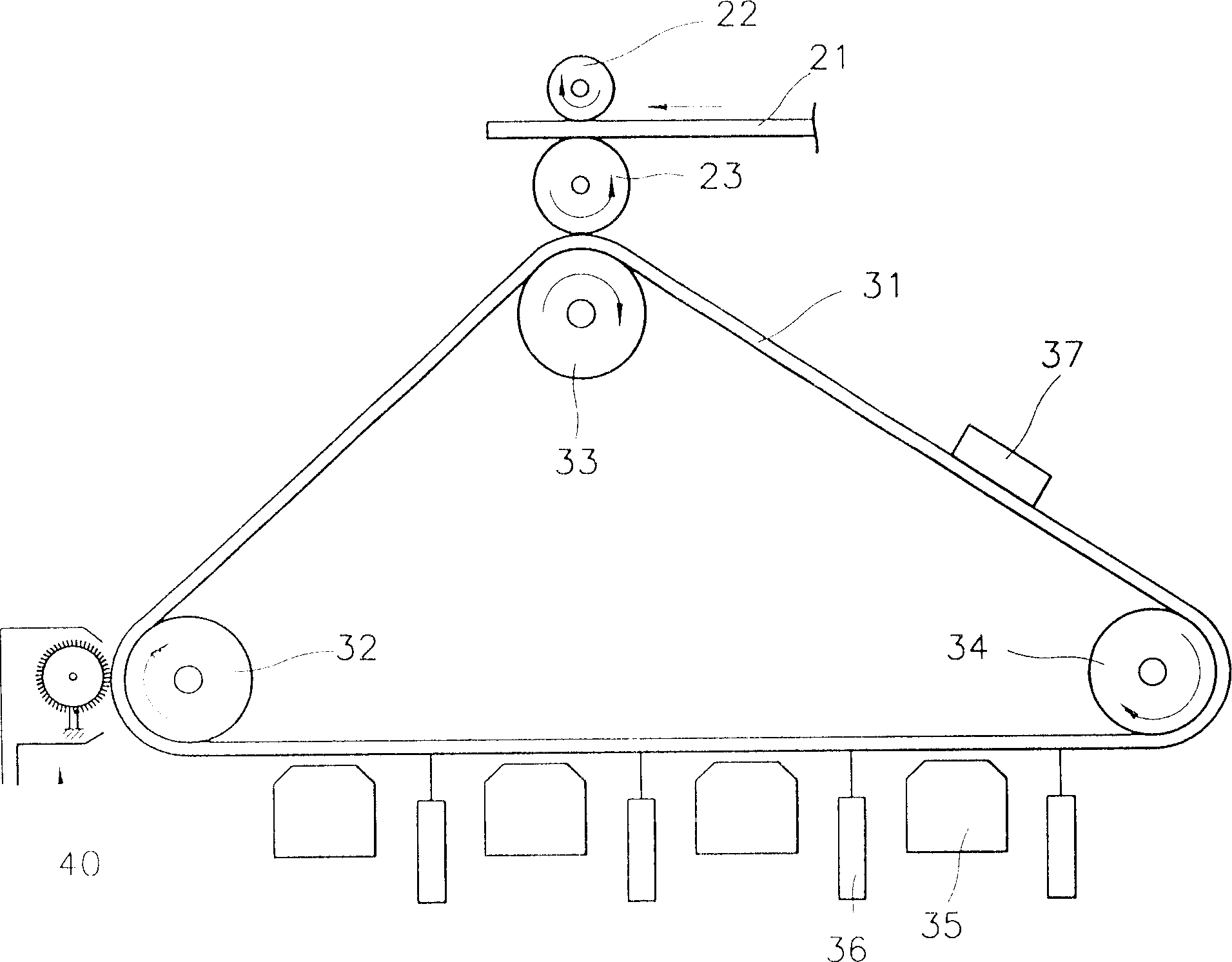

[0016] Such as image 3 As shown, the photosensitive belt 31 is rotatably mounted by a drive roller 32, a backup roller 33 and a control roller 34, and along the rotation path of the photosensitive belt 31, a plurality of electrostatic latent image forming devices 36, a plurality of developing devices 35, a Dryer 40 and a transfer mechanism.

[0017] A plurality of latent electrostatic image forming mechanisms 36, each having a laser scanner, scan the laser on the photosensitive belt 31 and generate a potential difference within the photosensitive belt 31, and form an electrostatic latent image based on the potential difference.

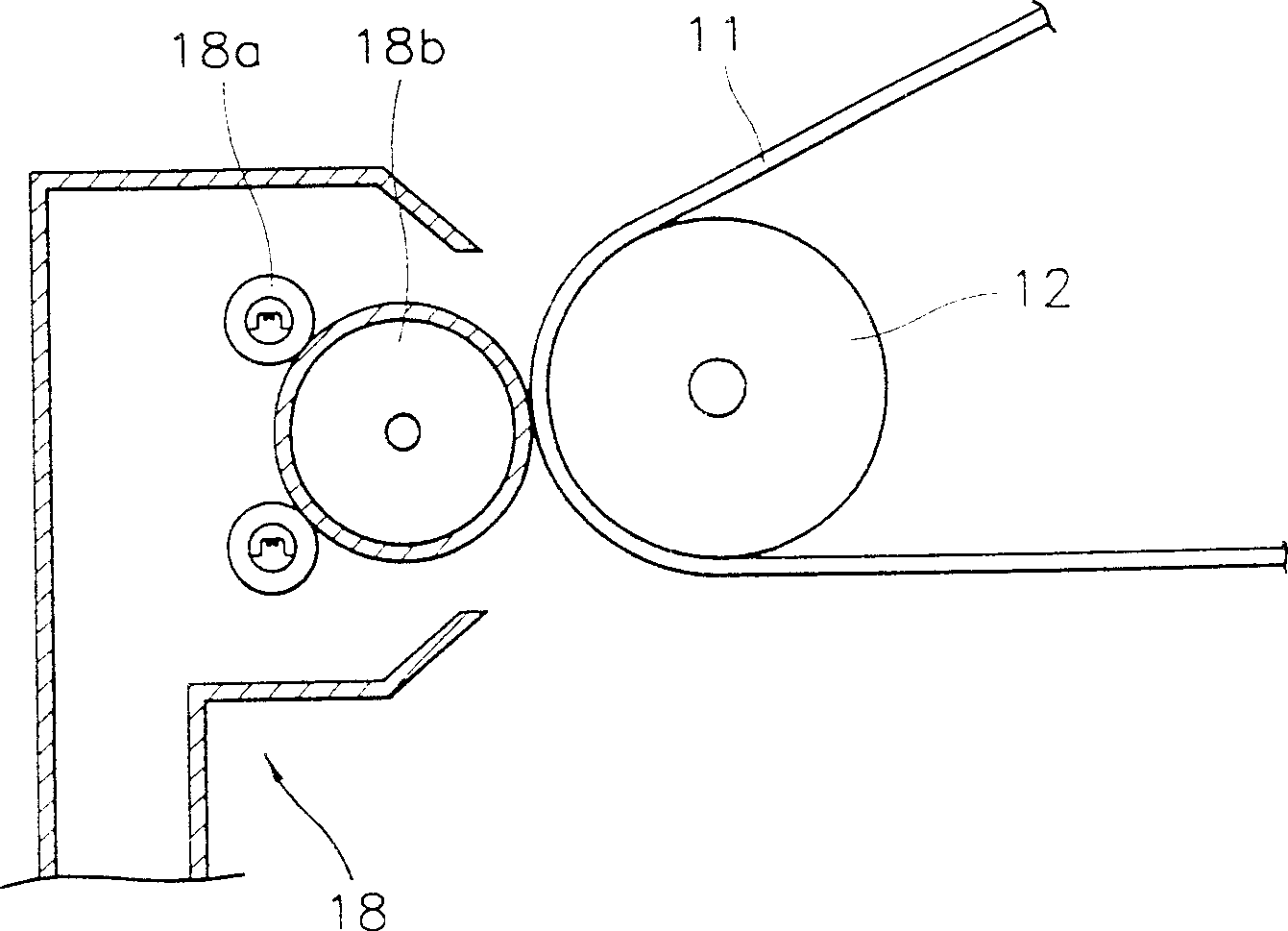

[0018] Along the rotation path of the photosensitive belt 31, a plurality of developing devices 35 and a main charger 37 are installed, each developing device 35 forms a toner image on the photosensitive belt 31, and the main charger 37 is used to make the surface of the photosensitive belt 31 With a uniform voltage, a transfer mechanism is installe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com