Lead scandium niobate-lead magnesium niobate-lead titanate ferroelectric single crystal and preparation method thereof

A lead magnesium niobate, ferroelectric single crystal technology, applied in the field of crystal technology and functional materials, can solve the problems of difficult growth of ferroelectric single crystal, no suitable high-power devices, etc., achieves small equipment investment, improves sensitivity and energy The effect of converting density, increasing detection range and resolution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] 0.01PSN-0.66PMN-0.33PT ferroelectric single crystal was grown by high temperature solution method.

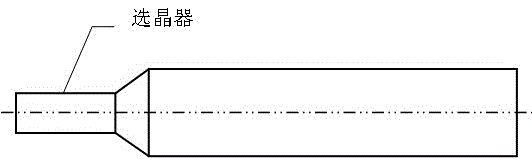

[0042] According to the chemical formula ScNbO 4 The composition of the initial raw material Nb 2 o 5 and Sc 2 o 3 , wet ball milling to mix evenly, and calcined at 1200 °C for 3 hours after compaction to synthesize the precursor ScNbO 4 ; According to the chemical formula MgNb 2 o 6 The composition of the initial raw material Nb 2 o 5 and 4MgCO 3 ·Mg(OH) 2 4H 2 O, wet ball milling to make it evenly mixed, compacted and calcined at 1000 °C for 6 hours to synthesize the precursor MgNb 2 o 6 ; According to the composition of 0.01PSN-0.66PMN-0.33PT, the initial raw materials PbO and TiO were weighed 2 and precursor ScNbO 4 , MgNb 2 o 6 Prepare the crystal raw material; the cosolvent is PbO, and the amount of the cosolvent added is 80% of the total mass of the raw material; the crystal raw material and the cosolvent are mixed uniformly by wet ball milling, an...

Embodiment 2

[0044] 0.04PSN-0.63PMN-0.33PT ferroelectric single crystal was grown by high temperature solution method.

[0045] Precursor ScNbO 4 , MgNb 2 o 6 The preparation is the same as in Example 1, and the initial raw materials PbO and TiO are weighed according to the composition of 0.04PSN-0.63PMN-0.33PT 2 and precursor ScNbO 4 , MgNb 2 o 6 Prepare the crystal raw material; the cosolvent is PbO, and the amount of the cosolvent added is 80% of the total mass of the raw material; the crystal raw material and the cosolvent are mixed uniformly by wet ball milling, and the ball milling time is 10 hours; the uniformly mixed raw material is put into a platinum crucible, and the platinum After the crucible is covered, it is placed in a crystal growth furnace to feed the material. The temperature of the feed is 1300°C, and the holding time is 10 hours; after the raw material is melted, it is continuously and slowly cooled at a slow cooling rate of 8°C / day, and the end temperature of the...

Embodiment 3

[0047] 0.06PSN-0.60PMN-0.34PT ferroelectric single crystal was grown by high temperature solution method.

[0048] According to the chemical formula ScNbO 4 The composition of the initial raw material Nb 2 o 5 and Sc 2 o 3 , dry ball milling to mix evenly, and calcined at 1200 °C for 3 hours after compaction to synthesize the precursor ScNbO 4 ; According to the chemical formula MgNb 2 o 6 The composition of the initial raw material Nb 2 o 5 and MgO, dry ball milling to make it evenly mixed, compacted and calcined at 1000°C for 6 hours to synthesize the precursor MgNb 2 o 6 ; Take the initial raw material Pb according to the composition of 0.06PSN-0.60PMN-0.34PT 3 o 4 、TiO 2 and precursor ScNbO 4 , MgNb 2 o 6 Preparation of crystal raw materials; cosolvent using Pb 3 o 4, the amount of co-solvent added is 55% of the total mass of raw materials; the crystal raw material and co-solvent are mixed evenly by dry ball milling, and the ball milling time is 20 hours; ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| piezoelectric charge coefficient | aaaaa | aaaaa |

| transition temperature | aaaaa | aaaaa |

| piezoelectric charge coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com