Auxiliary desertification control vehicle with grass checks

A sand control vehicle and grass grid technology, applied in botany equipment and methods, sowing seeders, planter parts, etc., can solve the problems of poor growth environment, high cost and time, low germination rate of grass grains, etc. , to increase the germination rate, ensure the growth environment, and facilitate the effect of rooting and germination

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] In order to make the content of the present invention more clearly understood, the present invention will be further described in detail below based on specific embodiments and in conjunction with the accompanying drawings.

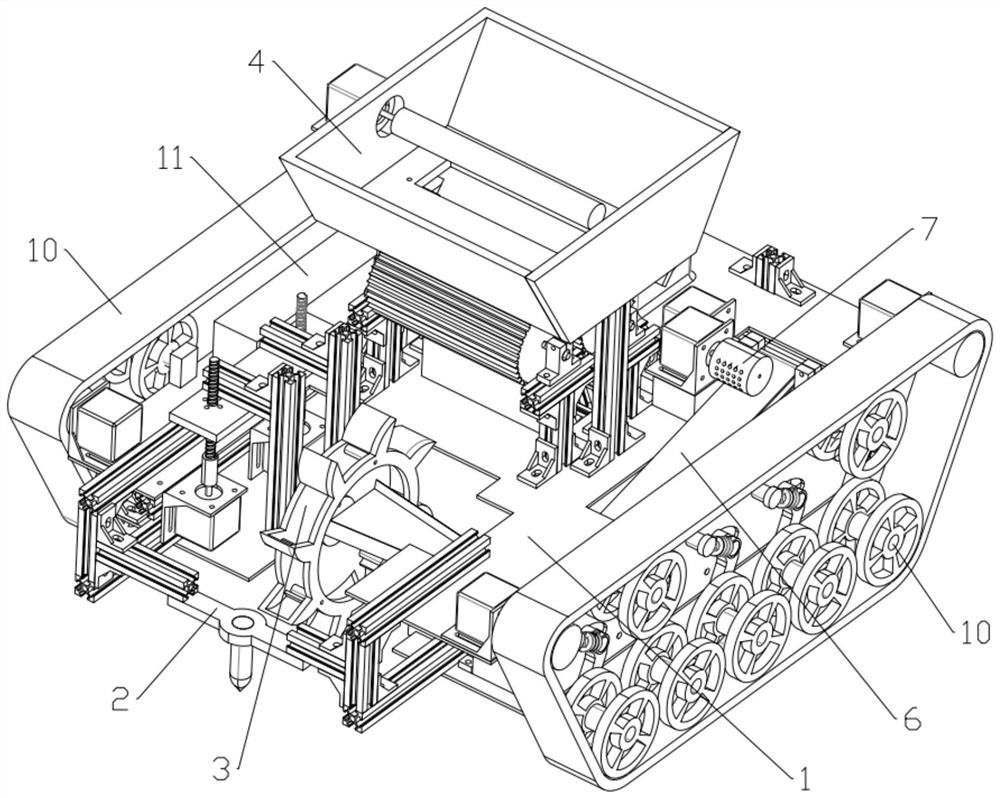

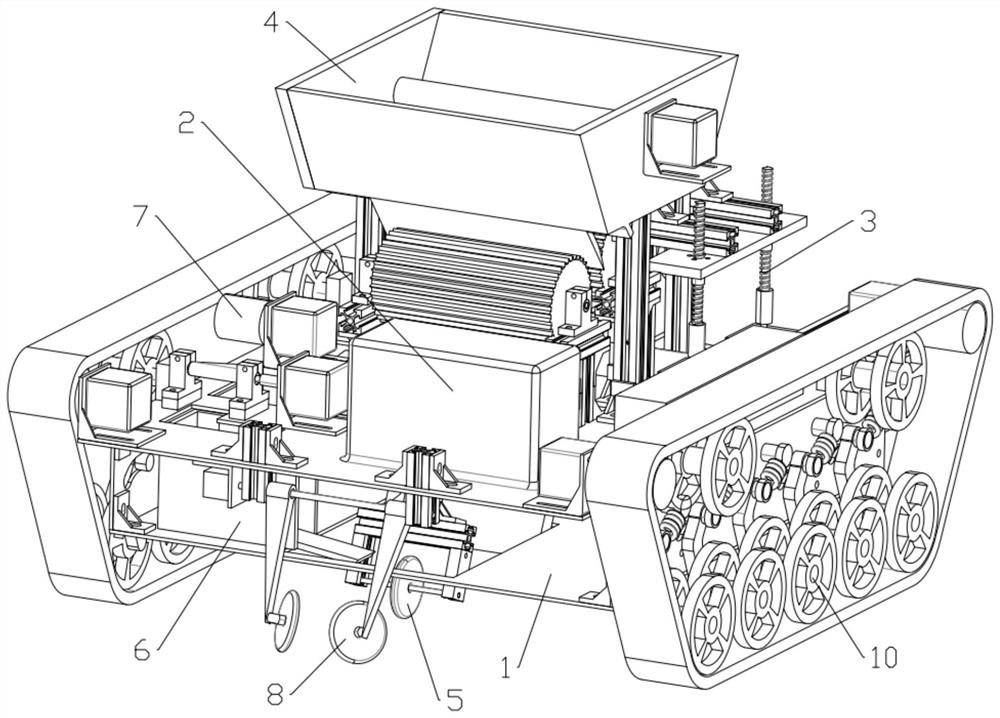

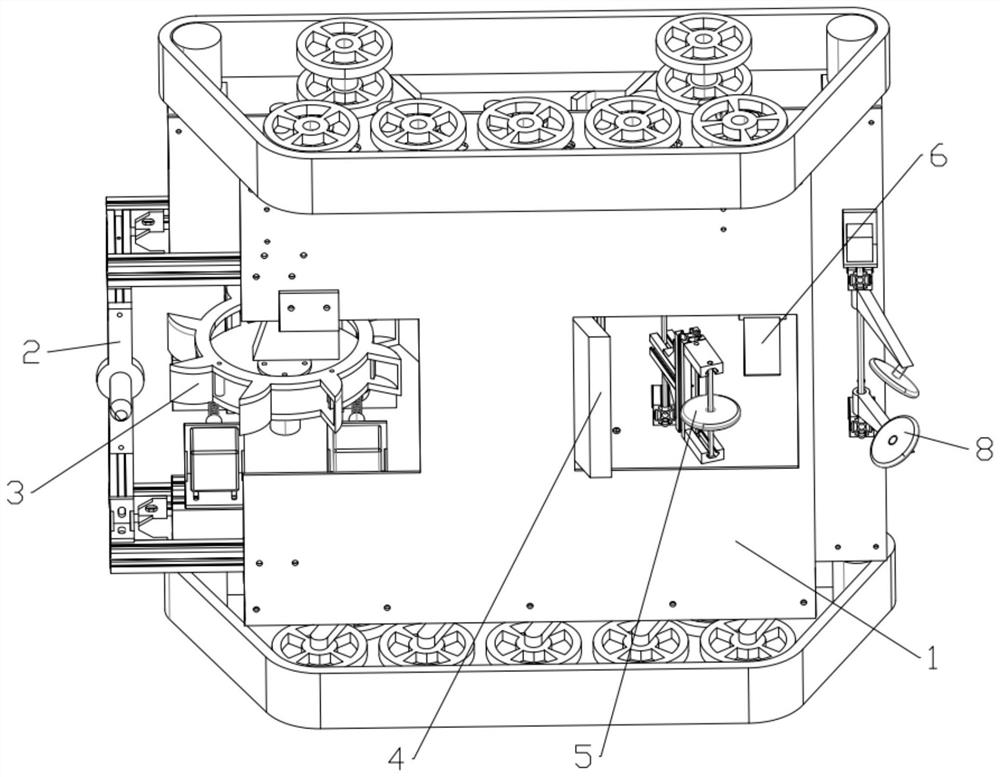

[0047] Such as Figure 1-10As shown, in this embodiment, a kind of grass grid auxiliary sand control vehicle is provided, which includes a car body 1, a sprinkler 2, a slotting device 3, a grass feeding device 4, a compacting device 5, a transmission device 6, a seeding Device 7 and ridge helping device 8. Wherein the carriage body 1 both sides has wheel 10, and wheel 10 is preferably the tank wheel that is suitable for uneven land, and accumulator 11 is housed on carriage body 1 in addition, so that supply energy for each device, carriage body 1 interior is also provided with control operation. module. The sprinkler device 2 is installed on the carriage body 1 for wetting the front sand during driving; the slotting device 3 is arranged at the fr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com