Local chord support combined grid structure

A network frame structure and network frame technology, applied in the direction of building structure, construction, etc., can solve the problems of large indoor space occupation and limited application scenarios, and achieve the effect of less occupation, favorable design, and strong adaptability of roof modeling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

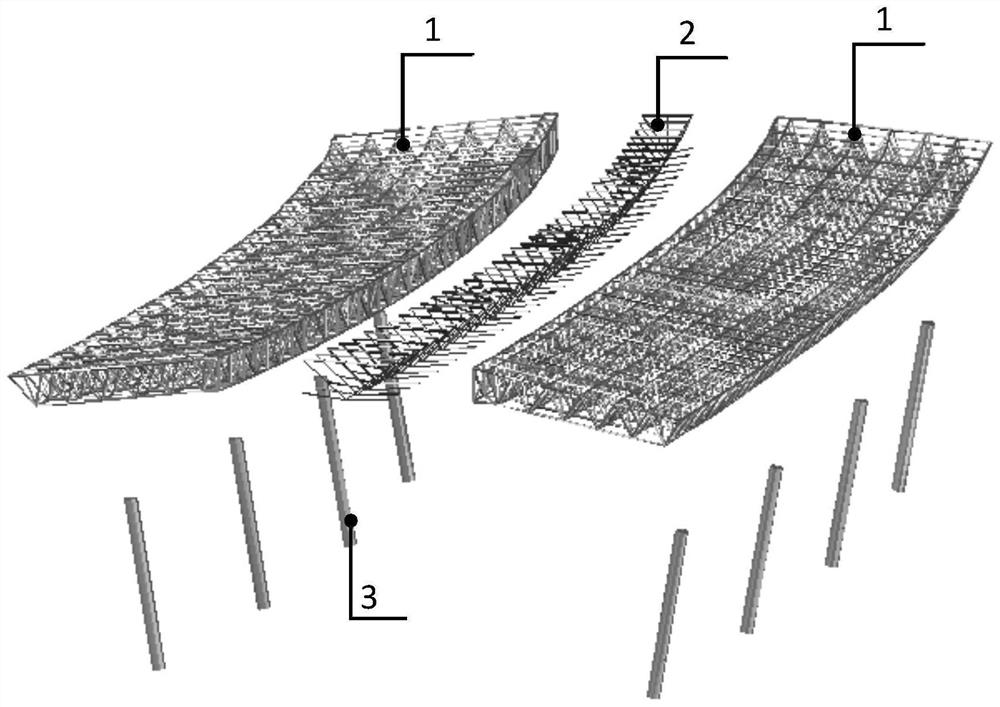

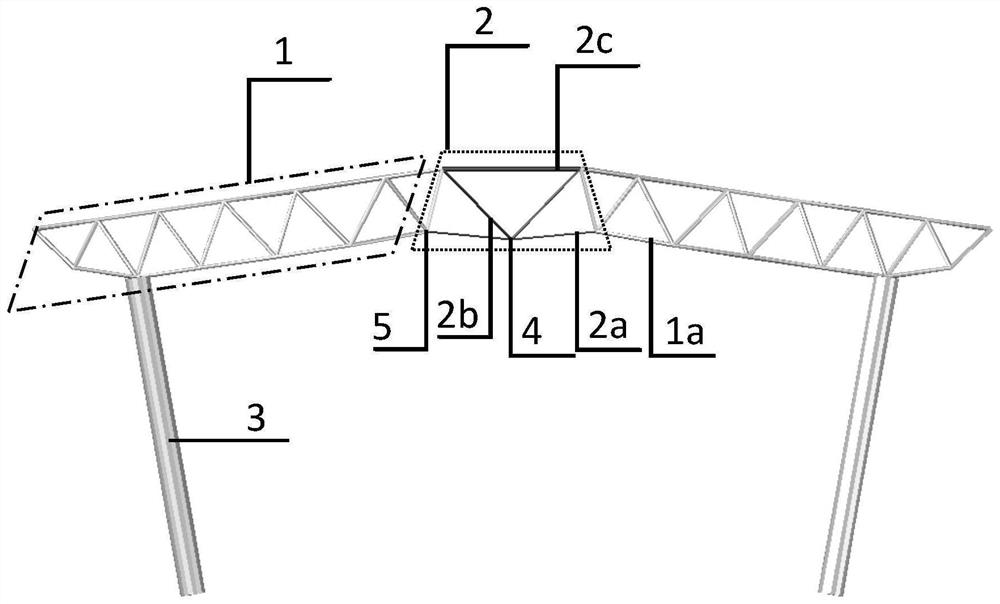

[0041]This embodiment provides a local chord-support combined grid structure, including the grid, and also includes the plane truss 2; the grid at the mid-span of the grid is replaced by the plane truss 2, and the non-mid-span of the grid adopts an orthogonal Just put the quadrangular pyramid grid frame 1. The upper chord 2c of the planar truss 2 is connected with the upper chords of the network frames on both sides, and the lower chord 2a of the planar truss 2 is connected with the lower chords 1a of the network frames on both sides; the lower chord 2a adopts a tensionable As for the chord, the lower chord 2a adopts a steel tie rod or a steel cable. Different from the existing string structure layout, in this embodiment, the string structure "plane truss 2" replaces part of the structure of the grid itself to realize embedded assembly and obtain a new type of hybrid grid structure, which can reduce the number of support columns It can bear the effect of horizontal thrust wit...

Embodiment 2

[0043] Further improvement on the basis of Example 1, the lower chord 2a adopts a double-rod arrangement, and the lower chord 2a is hingedly connected to the grid lower chord 1a through the connection node II5; the connection node II5 includes two pin lugs II5a, Two hollow spherical caps 5b and an ear plate are connected to the round pipe 5c.

[0044] The axial ends of the lug plate connecting pipe 5c are arranged in sequence from the inside to the outside with the pin lug plate II5a and the hollow spherical crown 5b, that is, according to the hollow spherical crown 5b, the pin shaft lug plate II5a, the lug plate connecting circular pipe 5c, and the pin shaft The order of lug plate II5a and hollow spherical crown 5b is welded and connected in sequence to form an integrated structure. The two pin shaft lug plates II5a are symmetrically arranged with the lug plate connecting round pipe 5c as the base point, and the two hollow spherical crowns 5b are arranged with the lug plate co...

Embodiment 3

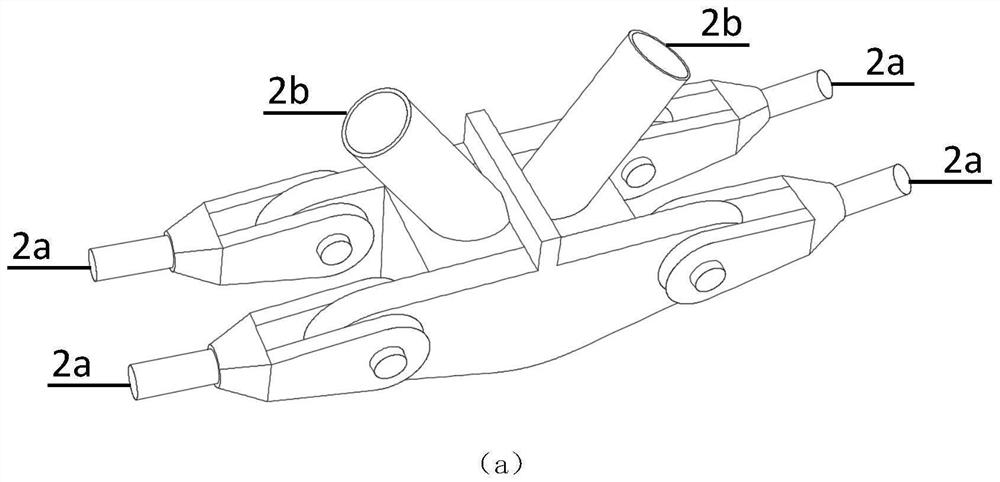

[0047] On the basis of embodiment 2, it is further improved, and also includes connection node I4; the plane truss 2 includes an upper chord 2c, two braces 2b and four lower chords 2a; The ends of the struts 2b are connected, the lower ends of the two struts 2b are connected to the connecting node I4, the upper chord 2c and the struts 2b form an inverted isosceles triangle structure; one end of the lower chord 2a is hingedly connected to the connecting node I4, and the other end is connected to the The pin lug plate II5a connecting the node II5 is hingedly connected.

[0048] The connection node I4 includes a pin lug plate I4a, a strut connecting plate 4b, a coordinating stiffener plate 4c and a pin shaft I4d. The two pin lugs I4a are connected through the strut connecting plate 4b, and the two pin lugs I4a have the same structure, and the plate surfaces are arranged parallel and symmetrical to each other; holes are provided at both axial ends of each pin lug I4a, through The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com