Prefabricated lightweight aggregate composite insulation board for building decoration construction

A composite thermal insulation and architectural decoration technology, which is applied in the direction of architecture, building structure, synthetic resin layered products, etc., can solve the problems of reducing the service life of thermal insulation panels, lack of reinforced structure, single structure of thermal insulation panels, etc., to reduce heat transfer , Avoid fracture, toughness and enhanced deformation ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

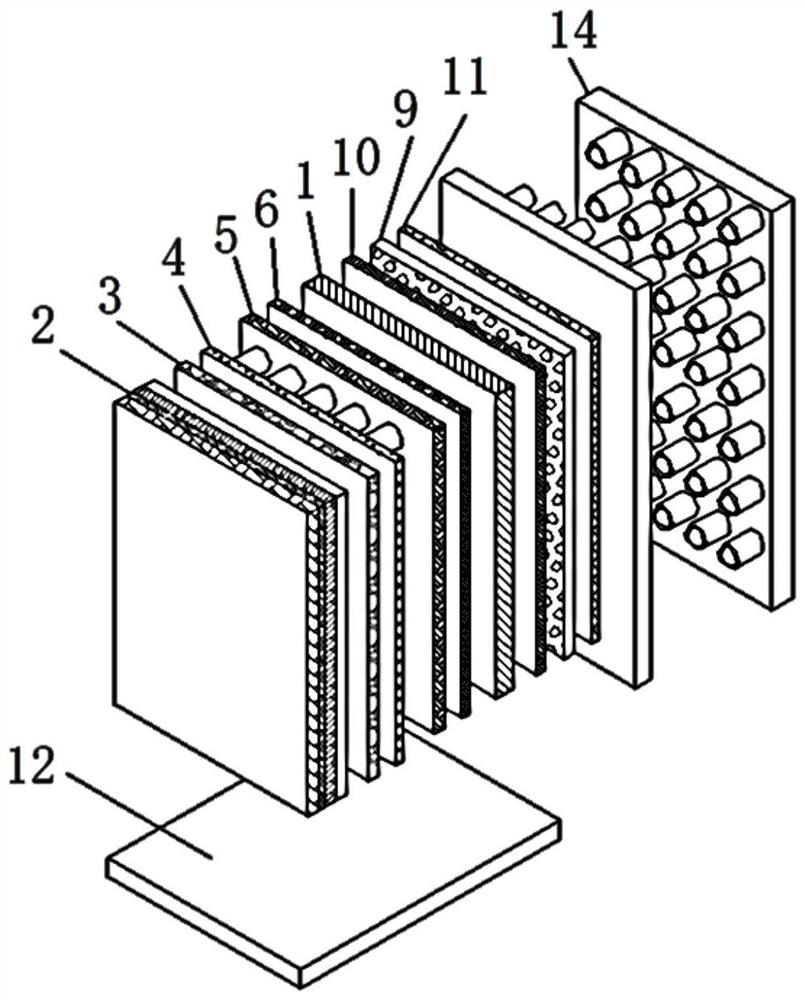

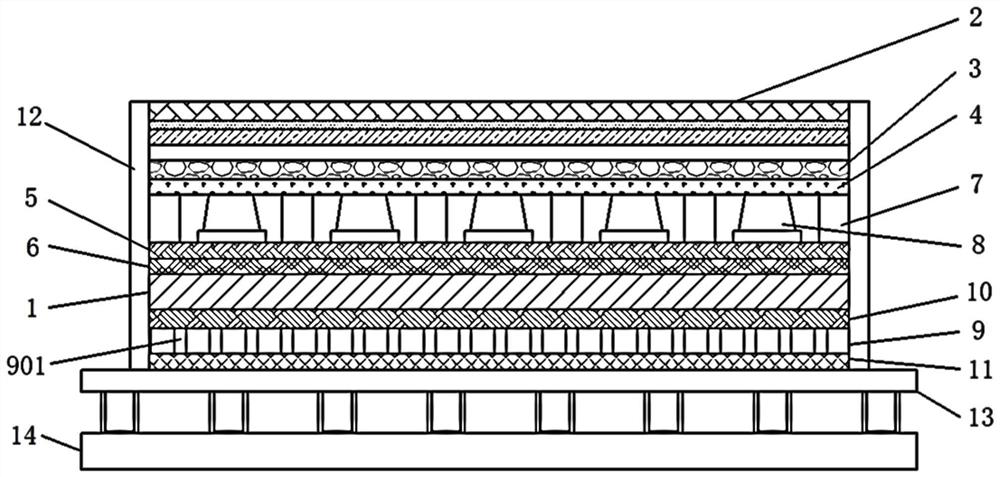

[0035] see figure 1 , figure 2 and Figure 5 , a prefabricated lightweight aggregate composite thermal insulation board for architectural decoration construction, the prefabricated lightweight aggregate composite thermal insulation board for architectural decoration construction includes a thermal insulation substrate 1, the bottom surface of the thermal insulation substrate 1 is provided with a phenolic plastic foam board 10, and the thermal insulation substrate 1 The top surface of the anti-deformation mechanism is provided with an anti-deformation mechanism, the top surface of the anti-deformation mechanism is provided with an inner support mechanism, the top of the inner support mechanism is provided with absorbent paper 4, and the top surface of the absorbent paper 4 is provided with a waterproof membrane 3.

[0036] Specifically, the composite thermal insulation board is provided with an installation space through the thermal insulation substrate 1, and the thermal ins...

Embodiment 2

[0043] Such as Figure 4 As shown, a prefabricated lightweight aggregate composite insulation board for building decoration construction includes a fireproof mechanism 2, and the top of the waterproof membrane 3 is equipped with a fireproof mechanism 2, and the fireproof mechanism 2 includes a fireproof grid cloth 201, a fireproof coating 202, glass Cotton board 203 and heat insulation layer 204, the top surface of waterproof membrane 3 is provided with heat insulation layer 204, and the top surface of heat insulation layer 204 is equipped with glass wool board 203, and the top surface of glass wool board 203 is provided with fireproof coating 202, The top surface of the fireproof coating 202 is equipped with a fireproof grid cloth 201, and both sides of the thermal insulation substrate 1 are equipped with sealing plates 12, and the surfaces of the two sealing plates 12 that are close to each other are respectively attached to the two sides of the fireproof grid cloth 201. . ...

Embodiment 4

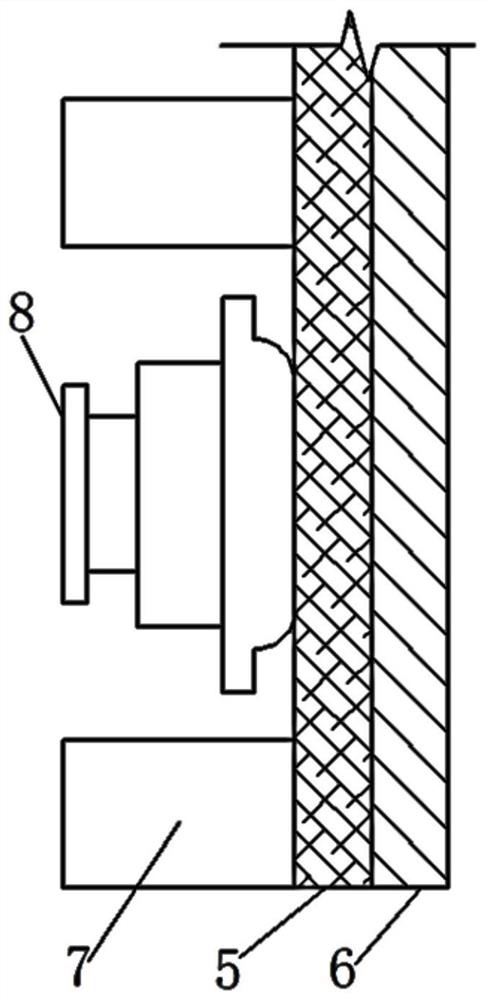

[0048] Such as image 3 , Figure 6-Figure 8 As shown, a prefabricated lightweight aggregate composite thermal insulation board for building decoration construction has an anti-deformation part 8 in the prefabricated lightweight aggregate composite thermal insulation board for building decoration construction, and the anti-deformation part 8 includes a first abutting plate 801, a second The abutting plate 802, the first intermediate abutting cover 803 and the second intermediate abutting cover 804, the first abutting plate 801 is arranged on the first intermediate abutting cover 803, the first intermediate abutting cover 803 is arranged in the second middle On the abutment cover 804, the second abutment plate 802 is provided with an inner groove 805, so that the middle and outer edge of the second abutment plate 802 protrude outward, and the second intermediate abutment cover 804 is arranged on the second abutment plate 802. On the top plate 802 and located in the inner groov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com