Turbine blade air film cooling structure and gas turbine adopting same

A technology of air film cooling and turbine blades, which is applied in the direction of blade support components, mechanical equipment, engine components, etc., can solve the problems of small coverage, loss of blade protection, poor cooling protection ability, etc., to improve cooling efficiency and improve Effect of air film coverage and cooling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

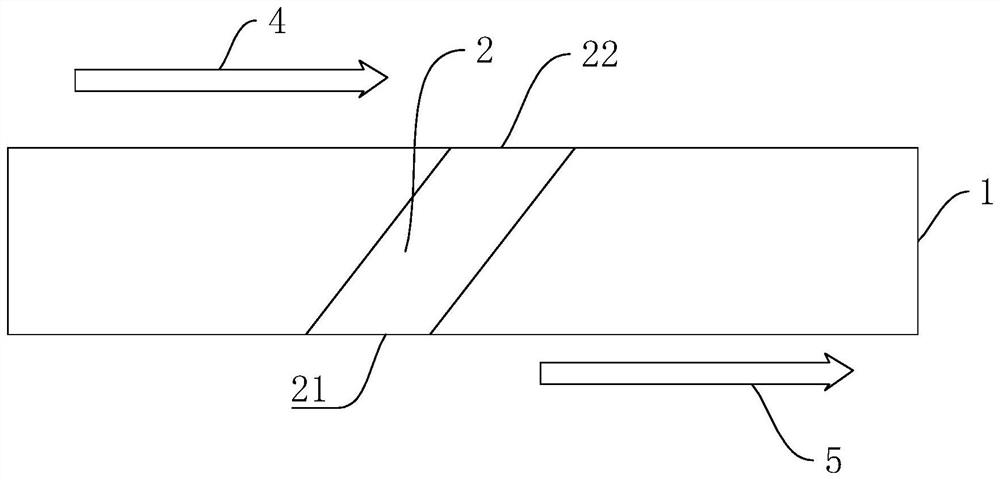

[0047] Such as Figure 7 and Figure 8 As shown, it is a turbine blade air film cooling structure, including the air film channel 2 opened on the surface of the turbine blade, the air film channel 2 is inclined, the air film channel 2 includes an inlet 21 and an outlet 22, and the inlet 21 is adjacent to the cooling The working medium 5 and the outlet 22 are adjacent to the high-temperature gas 4 .

[0048] A fluid oscillation generator 3 is arranged between the inlet 21 and the outlet 22. The cross-sectional dimension of the fluid oscillation generator 3 is larger than that of the air film channel 2, and the cross-sectional dimension of the fluid oscillation generator 3 suddenly increases. In this embodiment, the section of the fluid oscillation generator 3 is rectangular, and the distance between the fluid oscillation generator 3 and the inlet 21 is greater than the distance between the fluid oscillation generator 3 and the outlet 22 .

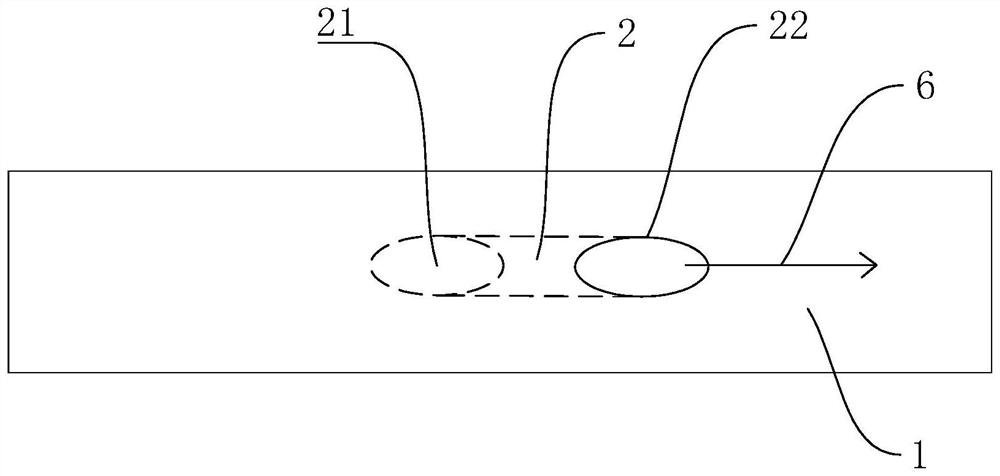

[0049] combine Figure 9 and Fig...

Embodiment 2

[0052] The difference between this embodiment and Embodiment 1 is that the fluid shock generator 3 is arranged in an arc shape perpendicular to the two sides of the gas film channel 2 (such as Figure 11 ).

[0053] Such as Figure 11 and Figure 12 As shown, the cooling working medium 5 enters the fluid oscillation generator 3 from the inlet 21, and periodically oscillates inside the fluid oscillation generator 3, so that the direction of the outlet cold air 6 at the outlet 22 of the gas film channel 2 is periodically oscillated, The outlet cold air 6 forms periodic air film coverage on the side wall surface of the blade wall 1 adjacent to the high-temperature gas 4, which plays a better role in protecting the blade wall 1.

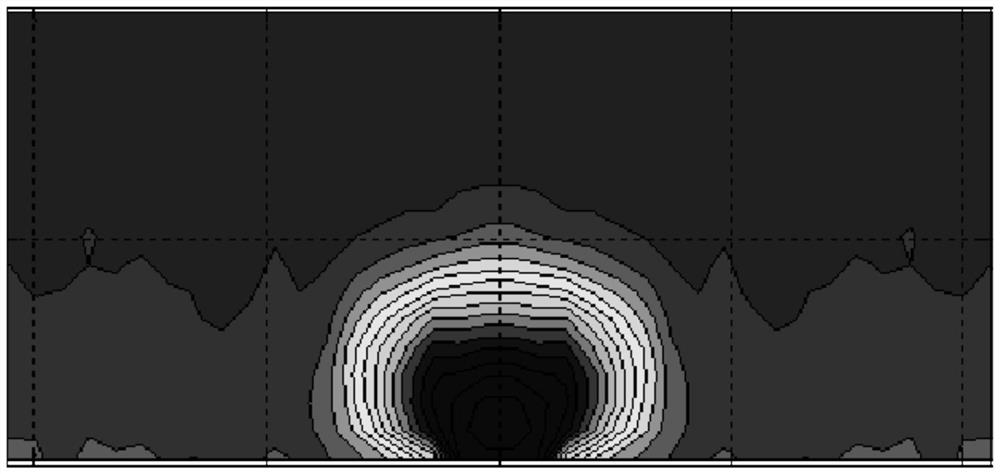

[0054] Such as Figure 13 As shown, the numerical simulation results show that the local cold air coverage of the film cooling hole based on fluid oscillation is enlarged, and there is good cold air coverage within the range of ±2.5 times the aperture...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com