Telescopic control system of crane and crane

A telescopic control and crane technology, applied in cranes, fluid pressure actuation system testing, mechanical equipment, etc., can solve problems such as vehicle vibration, loud boom back-buckling noise, uncontrollable retraction speed, etc., and achieve retraction speed. Precise control, solve the vibration of the whole vehicle, and solve the effect of large upside down sound

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

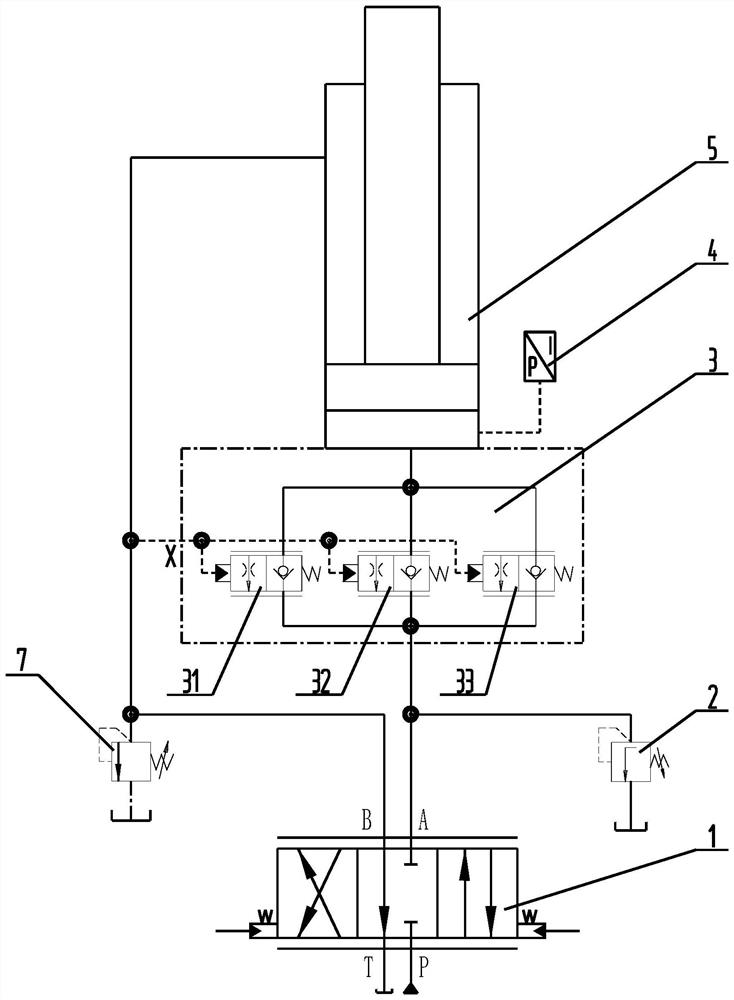

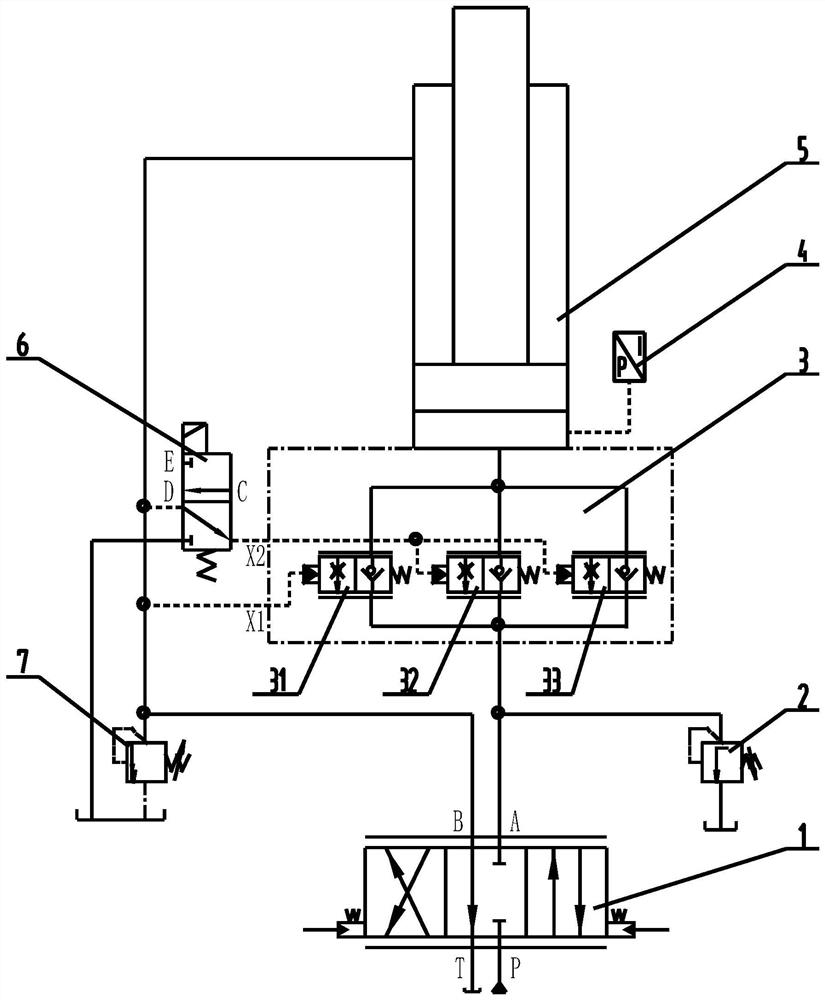

[0030] This embodiment discloses a telescopic control system for a crane. Aiming at the problems existing in the existing telescopic system, this patent provides a new telescopic control system. By grouping and controlling the telescopic balance valve group, the retractable boom can be retracted according to the operating conditions. It is divided into two modes of high-speed retraction and low-speed micro-motion retraction. At the same time, the external control pilot is used to control the oil circuit to achieve precise control of the opening of the telescopic balance valve, thereby realizing the control of the retraction speed of the boom. This application provides two telescopic control systems.

[0031] like figure 2 As shown, the first telescopic control system includes a telescopic control valve 1, a rodless chamber relief valve 2, a balance valve group 3, an oil pressure sensor 4, a telescopic oil cylinder 5, an electromagnetic reversing valve 6, and a rod chamber rel...

Embodiment 2

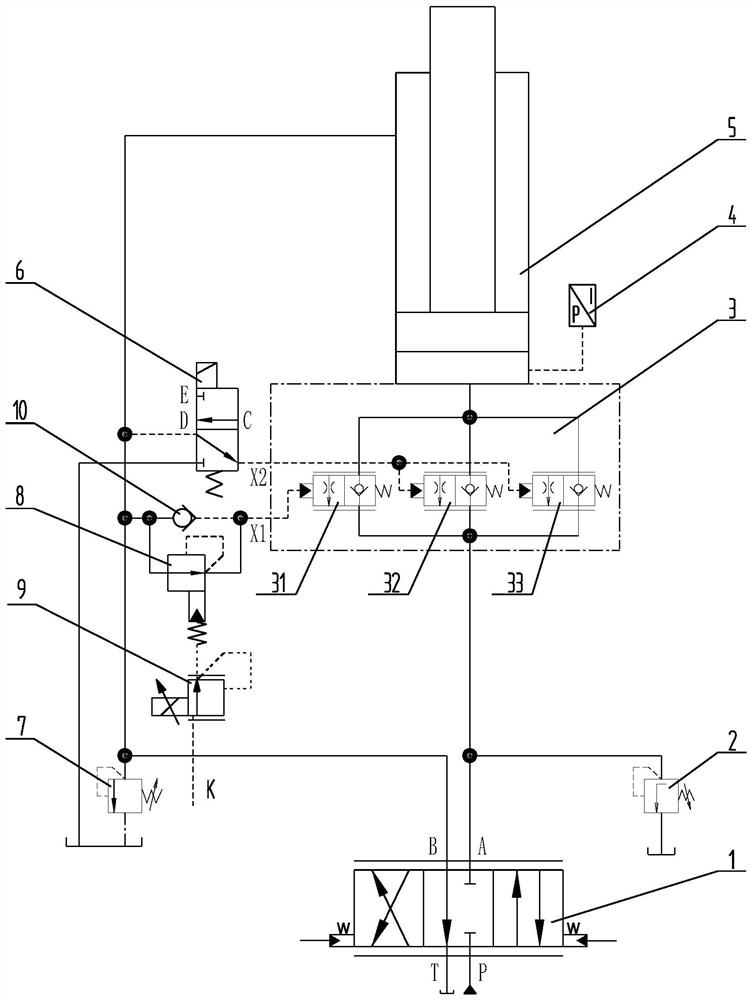

[0034] like image 3 As shown, the second telescopic control system mainly includes a telescopic control valve 1, a rodless chamber relief valve 2, a balance valve group 3, an oil pressure sensor 4, a telescopic oil cylinder 5, an electromagnetic reversing valve 6, and a rod chamber relief valve 7. Adjustable pressure reducing valve 8, electric proportional pressure reducing valve 9, one-way valve 10. Similarly, balance valve group 3 is composed of two or more groups of balance valves. In this embodiment, the first group of balance valves includes the first group of balance valves. A balance valve 31 , the second group of balance valves includes a second balance valve 32 and a third balance valve 33 .

[0035] The electromagnetic reversing valve 6 is used for group control of the balance valve group 3 , the X1 port controls the first balance valve 31 , and the X2 port controls the second balance valve 32 and the third balance valve 33 . Embodiment 1 Although the speed limit f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com