Filtering check valve and side block with same

A technology of check valve and filter screen, which is applied in the direction of filtration and separation, fixed filter element filter, control valve, etc., can solve the problems of side block thread damage, use of very large labor intensity, etc., and achieve the effect of dismantling the thread and saving labor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

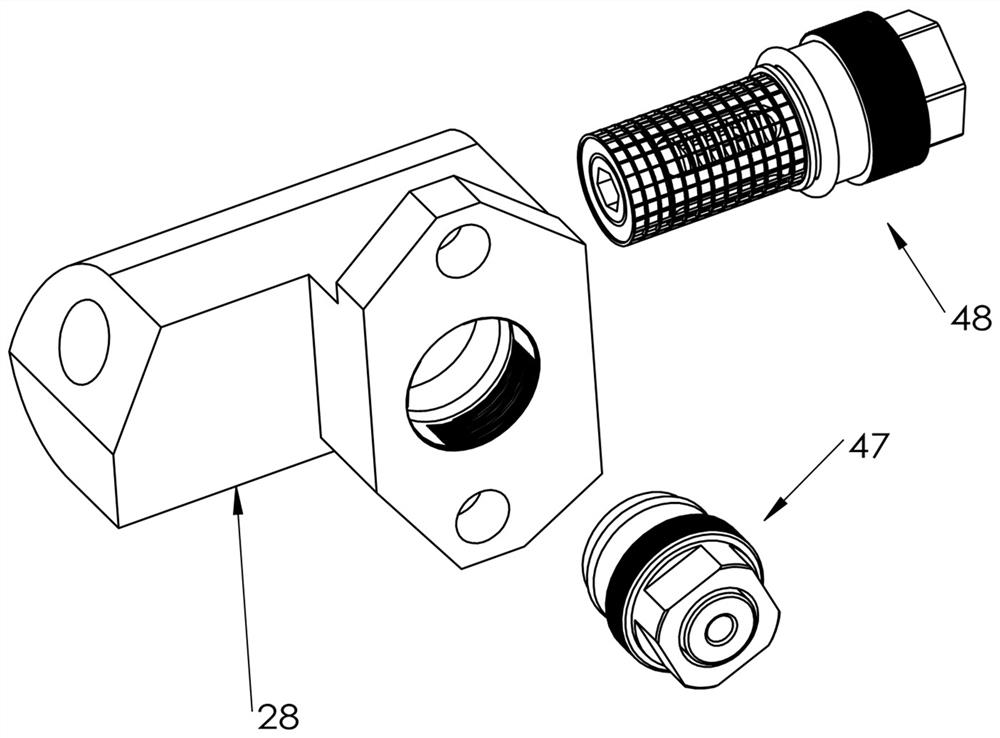

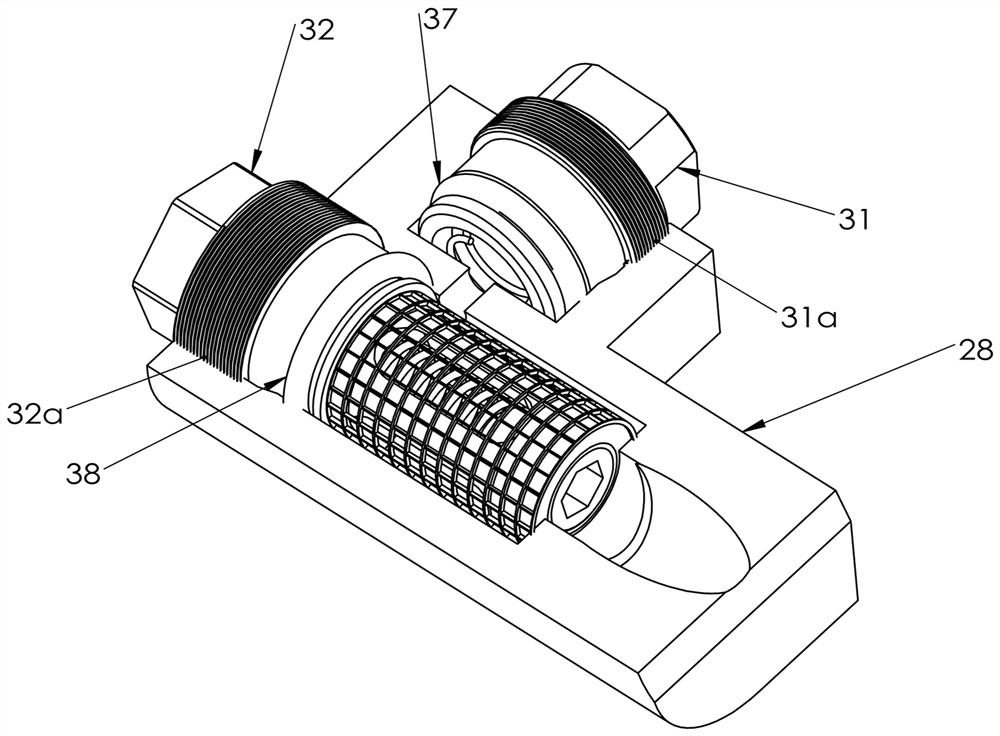

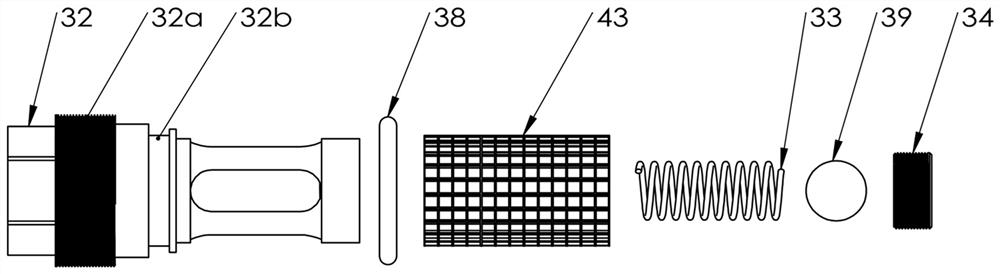

[0019] The filter check valve 48 is composed of a main body 32 , an O-ring 38 , a filter screen 43 , a spring 33 , a steel ball 39 and a valve seat 34 . One side of the thread 32a of the main body 32 is designed with an O-ring installation groove 32b. When the main body 32 is tightened on the side block housing 28, the position of the O-ring installation groove 32b is closer to the thread 32a. For fluid, install an O-ring 38 on the O-ring installation groove 32b to cooperate with the side block housing 28 to seal, so that the fluid will not touch the thread where the main body 32 and the side block housing 28 are fixed. In this way, there will be no problem that components such as resin or isocyanate crystallize and solidify at the thread to cause the thread to stick, so that the disassembly of the thread is very labor-saving and the thread will not be damaged.

[0020] There is a hole in the middle of the valve seat 34, and the fluid flows into the main body 32 through the va...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com