Anti-adherence protection patch for electronic product package

A technology for electronic products and packaging. It is applied in the field of anti-adsorption protective stickers for electronic product packaging. It can solve the problems of adhesion and adsorption, unfavorable protection of electronic products, scratches, etc., achieve high peeling force, improve comprehensive performance, and prevent scratches. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

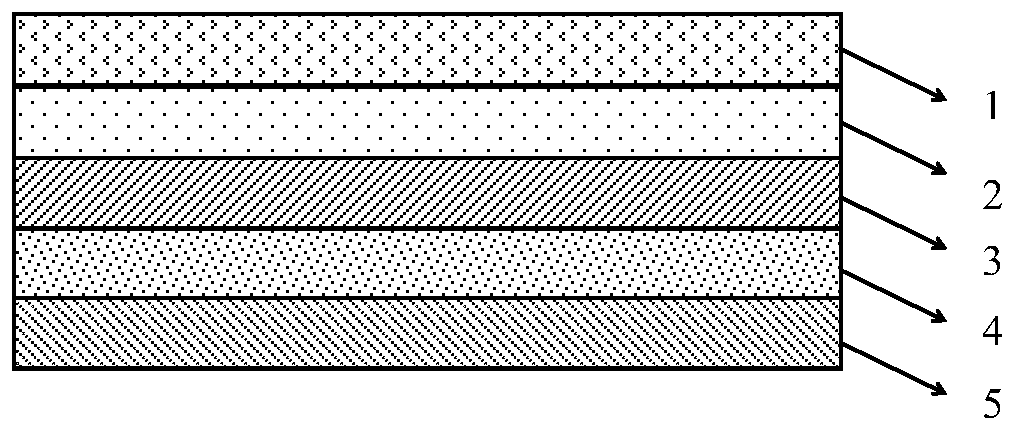

[0024] Embodiment 1: An anti-adsorption type protective sheet for electronic product packaging, the anti-adsorption type protective sheet includes an HC layer, an OCA layer, an optical PET layer, a silica gel layer and a release film laminated sequentially from top to bottom.

[0025] The HC layer includes the following components by weight: 80 parts of wear-resistant resin, 1 part of antistatic agent, 1 part of softener, 3 parts of curing agent, 50 parts of solvent, and 1 part of nano silicon dioxide.

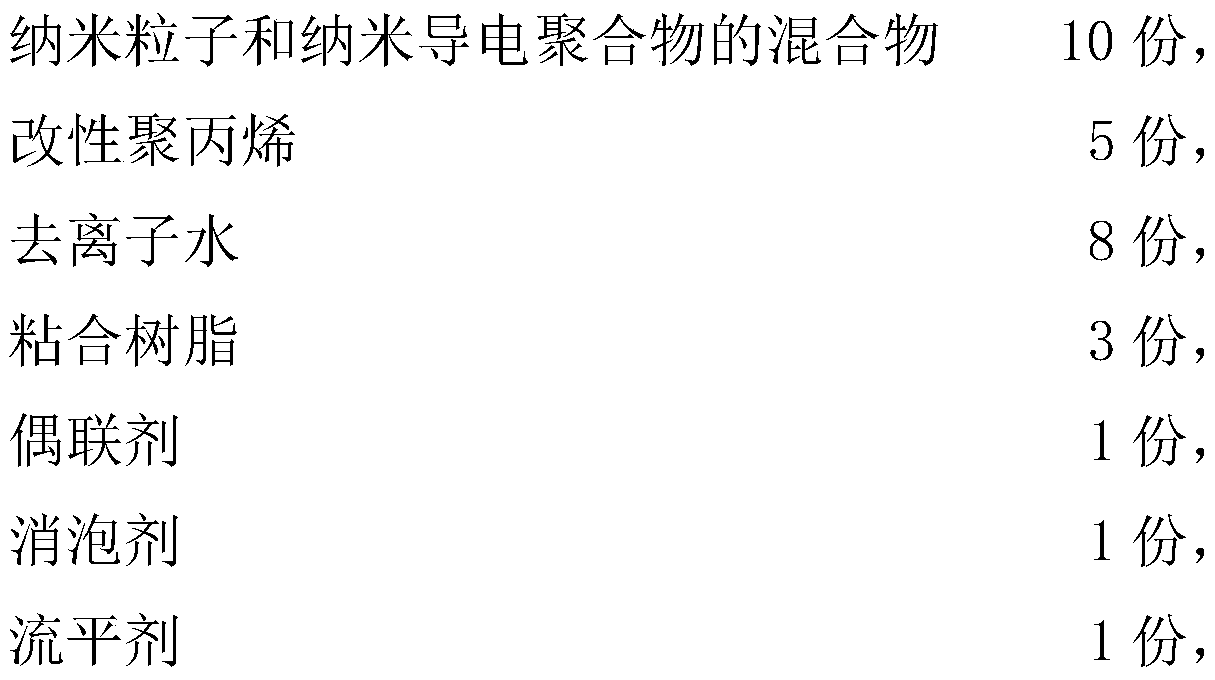

[0026] Wherein, the antistatic agent includes the following components in the above-mentioned corresponding parts by weight:

[0027]

[0028] Wherein, the mass ratio of the nanoparticles to the nanoconductive polymer is 3:10, the nanoparticles are titanium oxide, the nanoconductive polymer is polyaniline, and the modified polypropylene is carbon fiber modified polypropylene, The adhesive resin is melamine formaldehyde resin, the coupling agent is silane coupling agent kh57...

Embodiment 2

[0031] An anti-absorption type protective sticker for electronic product packaging, the anti-absorption type protective sticker includes an HC layer, an OCA layer, an optical PET layer, a silica gel layer and a release film laminated sequentially from top to bottom.

[0032] The HC layer includes the following components by weight: 80 parts of wear-resistant resin, 1 part of antistatic agent, 1 part of softening agent, 3 parts of curing agent, 50 parts of solvent, 1 part of nano silicon dioxide, the antistatic agent Parts by weight include the following ingredients:

[0033]

[0034] Wherein, the mass ratio of the nanoparticles to the nano-conducting polymer is 3:10, the nanoparticles are zinc oxide, the nano-conducting polymer is polytrimethylthiophene, and the modified polypropylene is asbestos-modified Polypropylene, the adhesive resin is LLDPE adhesive resin, the coupling agent is silane coupling agent kh792, the defoamer is phenylethyl alcohol oleate, and the leveling ...

Embodiment 3

[0037] An anti-absorption type protective sticker for electronic product packaging, the anti-absorption type protective sticker includes an HC layer, an OCA layer, an optical PET layer, a silica gel layer and a release film laminated sequentially from top to bottom.

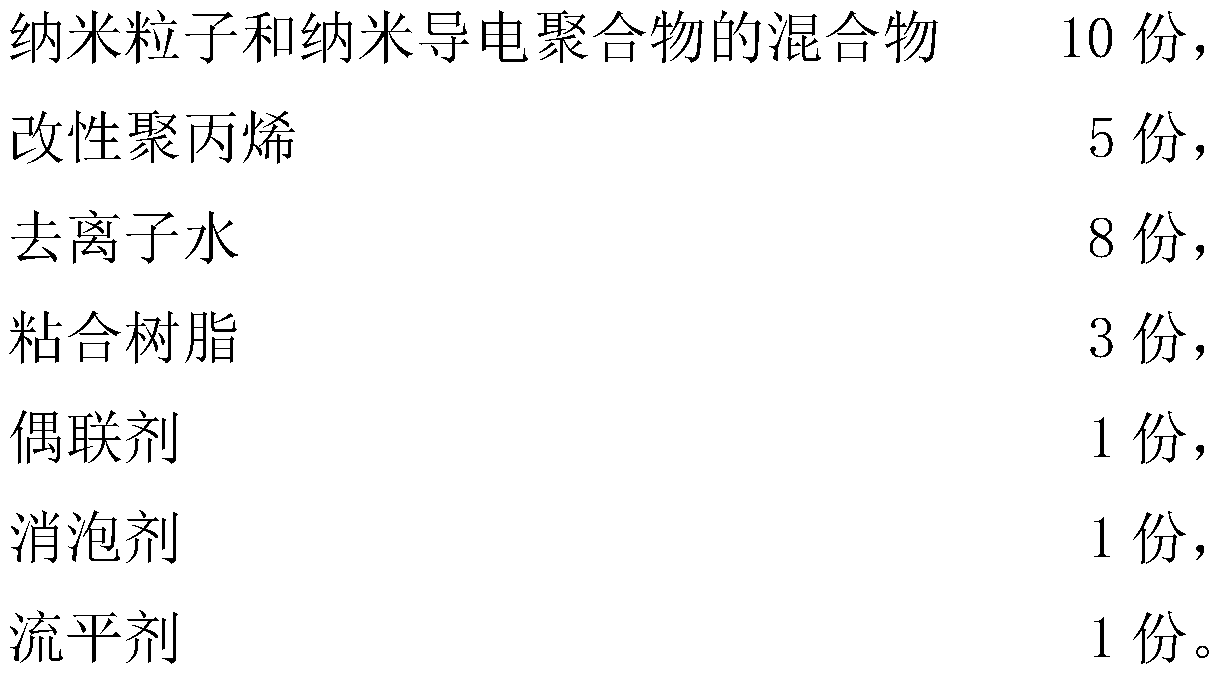

[0038] The HC layer includes the following components by weight: 100 parts of wear-resistant resin, 3 parts of antistatic agent, 5 parts of softening agent, 6 parts of curing agent, 100 parts of solvent, 13 parts of nano silicon dioxide, the antistatic agent Parts by weight include the following ingredients:

[0039]

[0040] Wherein, the mass ratio of the nanoparticles to the nanoconductive polymer is 4:9, the nanoparticles are titanium oxide, the nanoconductive polymer is polyaniline, and the modified polypropylene is glass-reinforced polypropylene, so The adhesive resin is melamine formaldehyde resin, the coupling agent is silane coupling agent kh570, the defoamer is tributyl phosphate, and the leveling age...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com