Method for treating valuable secondary materials such as electronic waste through oxygen inclined blowing rotary converter

A technology for electronic waste and materials, which is applied in the direction of furnace types, furnace components, waste heat treatment, etc., can solve the problems of large consumption of chemical reagents, low level of comprehensive recovery, low degree of automation, etc., and achieve wide use of materials and high operating temperature Effects with a large range and a high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

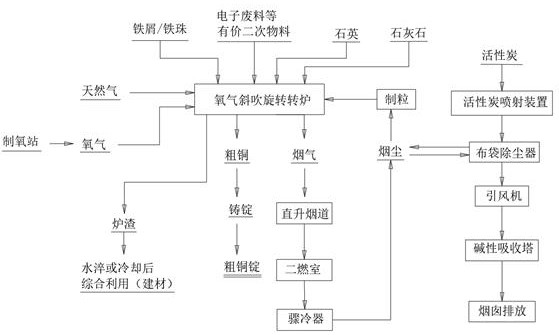

[0029] like figure 1 As shown, a method for processing valuable secondary materials such as electronic waste in an oxygen inclined-blown rotary converter comprises the following steps:

[0030] (1) Material preparation: Pretreatment of valuable secondary materials such as electronic waste. The treatment process can include crushing, washing, pressure filtration, drying, sintering, and screening. Finally, the particle size of the material is controlled between 5 and 300mm. The moisture should be controlled within 5%; the actual size of the material particle size is suitable for storage, transportation and being able to be put into the furnace.

[0031] (2) Ingredients: In terms of mass percentage, the ingredients are prepared according to the following proportions: 62% of valuable secondary materials such as electronic waste, 20% of iron filings or iron beads, 10% of quartz stone or silicon powder, and 8% of limestone; the above materials It can be placed in the batching bin, ...

Embodiment 2

[0036] A method for treating valuable secondary materials such as electronic waste in an oxygen inclined-blown rotary converter, comprising the following steps:

[0037] (1) Material preparation: Pretreatment of valuable secondary materials such as electronic waste. The treatment process can include crushing, washing, pressure filtration, drying, sintering, and screening. Finally, the particle size of the material is controlled between 5 and 300mm. The moisture should be controlled within 5%; the actual size of the material particle size is suitable for storage, transportation and being able to be put into the furnace.

[0038] (2) Ingredients: In terms of mass percentage, ingredients are prepared according to the following proportions: 92% electronic waste and other valuable secondary materials, 5% iron filings or iron beads, 2% quartz stone or silicon powder, 1% limestone; the above materials It can be placed in the batching bin, and it can be automatically metered, proporti...

Embodiment 3

[0043] A method for treating valuable secondary materials such as electronic waste in an oxygen inclined-blown rotary converter, comprising the following steps:

[0044] (1) Material preparation: Pretreatment of valuable secondary materials such as electronic waste. The treatment process can include crushing, washing, pressure filtration, drying, sintering, and screening. Finally, the particle size of the material is controlled between 5 and 300mm. The moisture should be controlled within 5%; the actual size of the material particle size is suitable for storage, transportation and being able to be put into the furnace.

[0045] (2) Ingredients: In terms of mass percentage, ingredients are prepared according to the following proportions: 80% electronic waste and other valuable secondary materials, 12% iron filings or iron beads, 5% quartz stone or silicon powder, and 3% limestone; the above materials It can be placed in the batching bin, and it can be automatically metered, pro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com