Automatic expansion and contraction device for mud pipe in jacking station in pipe jacking construction and use method of automatic expansion and contraction device

An automatic telescopic device, mud pipe technology, applied in the direction of pipes/pipe joints/pipes, flange connections, piping systems, etc., can solve the problems of high hose process requirements, poor connection integrity, easy to burst pipes, etc. The effect of security, strengthening integrity, and simple and convenient connection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

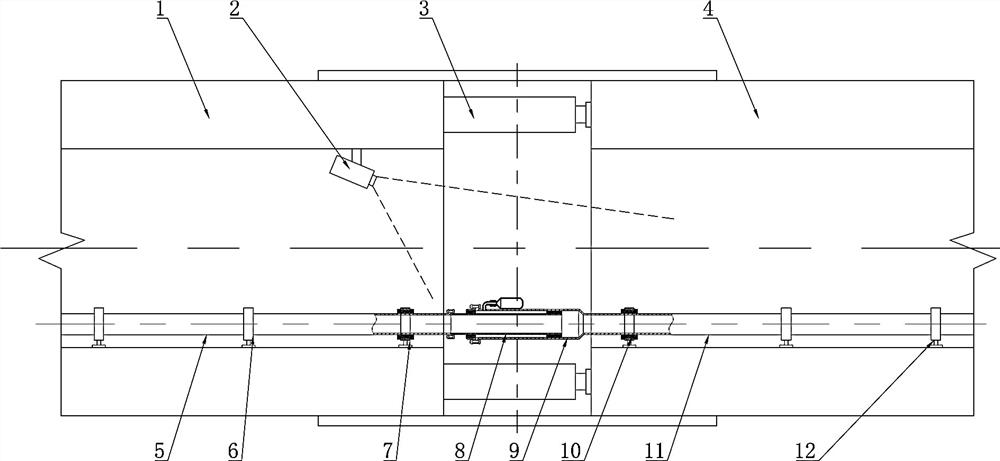

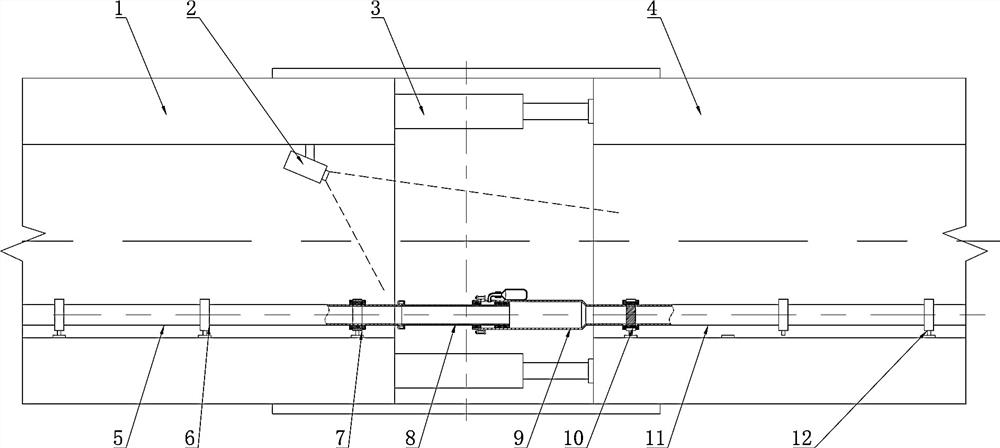

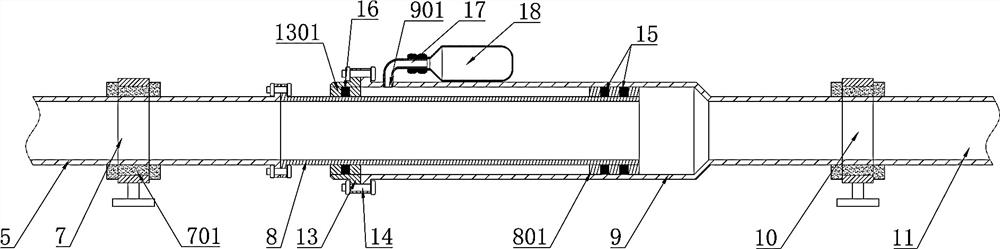

[0037] Such as Figure 1~8 As shown, a kind of automatic telescopic device for mud pipe in the relay room of pipe jacking construction, the relay room jack 3 is arranged between the first pipe joint 1 and the second pipe joint 4, and the first pipe joint 1 and the second pipe joint 4 pass through The mud pipes in the relay room are connected by an automatic telescopic device. The automatic telescopic device includes an inner pipe body 8 connected to the end of the first mud pipe 5 and an outer pipe body 9 connected to the end of the second mud pipe 11. The inner pipe body 8 It is sheathed inside the outer pipe body 9 , and the end of the outer pipe body 9 is provided with a sealing flange 13 , and the sealing flange 13 abuts against the outside of the inner pipe body 8 to form a seal. The device is connected to the mud pipe of the front and rear pipe joints through the clamp, and the device can also be freely expanded and contracted during the expansion and contraction process...

Embodiment 2

[0049] Further illustrate in conjunction with embodiment 1, as Figure 1-8 As shown, the end of the first mud pipe 5 is connected to the inner pipe body 8, and the first sealing ring 15 is installed between a plurality of first snap rings 801 at the end of the inner pipe body 8;

[0050] Install the outer pipe body 9 on the end of the second mud pipe 11, and insert the inner pipe body 8 into the outer pipe body 9;

[0051] Put the second sealing ring 16 on the inner pipe body 8, and then assemble the sealing flange 13 on the inner pipe body 8. When assembling the sealing flange 13, firstly clamp the second sealing ring 16 inside the sealing flange 13, and then Then connect the sealing flange 13 to the end of the outer pipe body 9;

[0052] Fill lubricating oil between the outer pipe body 9 and the inner pipe body 8 through the exhaust hole 901 of the outer pipe body 9;

[0053] Connecting pipe 17 is installed on exhaust hole 901, and expansion bottle 18 is installed at the e...

Embodiment 3

[0057] Further illustrate in conjunction with embodiment 1 and 2, as Figure 1-8 As shown, the inner pipe body 8 is welded three times with the first snap ring 801 to ensure that the welding is tight and durable, and the first sealing ring 15 is installed to ensure a tight fit.

[0058] Firmly fix the sealing flange 13 at one end of the outer pipe body 9, and open a hole at the end. Cut the sealing flange 13 from the middle, separate the upper and lower parts, and weld two circles of the second snap ring 1301 respectively to ensure that the welding is tight, firm and durable.

[0059] Put the inner pipe body 8 into the outer pipe body 9, connect the flange at one end of the outer pipe body 9 with the sealing flange 13, fix the first sealing ring 15 at one end of the inner pipe body 8, and complete the automatic mud pipe passing through the relay room. Installation of telescopic devices.

[0060] Connect the automatic telescopic device of the mud pipe passing through the rela...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com