Monolithic wafer cleaning device and overall cleanliness control method thereof

A control method, a single-chip technology, applied in cleaning methods and utensils, cleaning methods using gas flow, chemical instruments and methods, etc., can solve the problem of reducing yield, wafer etching, difficult to control wafer cleanliness, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

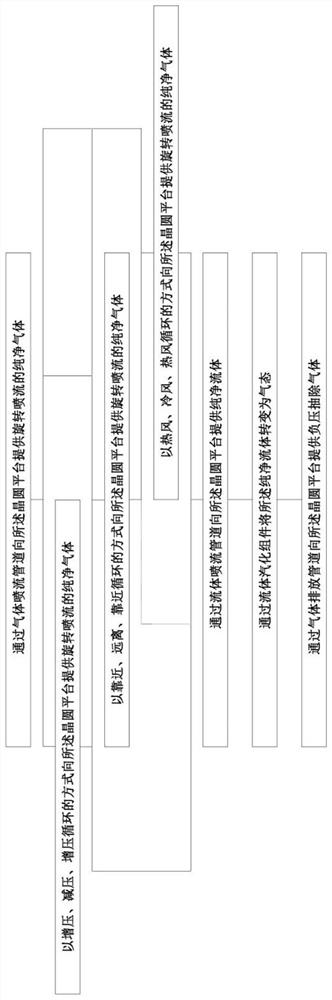

[0039] Such as figure 1 As shown, the present embodiment provides a method for controlling the overall cleanliness in the single-chip wafer cleaning process, including: in the cleaning process of the wafer, providing a rotating jet to the wafer platform through the gas jet pipeline. flow of pure carbon dioxide gas, and provide pure supercritical carbon dioxide fluid to the wafer platform through the fluid jet pipeline, and then convert the pure supercritical carbon dioxide fluid into a gaseous state through the fluid vaporization component, and then send it to the wafer platform through the gas discharge pipeline The wafer platform provides negative pressure pumping; where,

[0040] The process in which the gas jet pipeline provides the swirling jet flow of pure carbon dioxide gas to the wafer platform includes:

[0041] providing rotating jets of pure carbon dioxide gas to the wafer platform in the form of pressurization, decompression, and pressurization cycles; or / and

[...

Embodiment 2

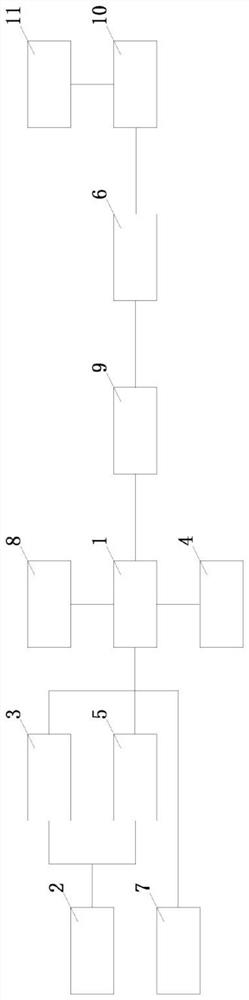

[0045] Such as figure 2 As shown, this embodiment provides a single-chip wafer cleaning device based on the control method described in Embodiment 1, including:

[0046] wafer platform 1;

[0047] The platform lifting assembly 4 is arranged at the bottom of the wafer platform 1, and is used to control the distance between the pure carbon dioxide gas and the wafer platform 1 during the rotating jet flow;

[0048] The gas jet flow pipeline 2 is used to provide the pure carbon dioxide gas of the rotating jet flow to the wafer platform 1;

[0049] A pressure regulating assembly 3, located at the outlet of the gas jet pipeline 2, is used to control the pressure of the pure carbon dioxide gas rotating jet;

[0050] The temperature adjustment assembly 5 is located at the outlet of the gas jet pipeline 2, and is used to control the temperature of the pure carbon dioxide gas during the rotating jet flow;

[0051] A fluid jet pipeline 7 is used to provide pure supercritical carbon d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com