Method for cleaning electronic-grade polycrystalline silicon production device and process pipe

A technology for production equipment and process pipelines, applied in the direction of liquid cleaning methods, cleaning methods and utensils, chemical instruments and methods, etc., can solve problems such as easy residual Na ions, P ions, wall thickness reduction, over-corrosion, etc. Achieve the effect of convenient realization, easy operation and high cleanliness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

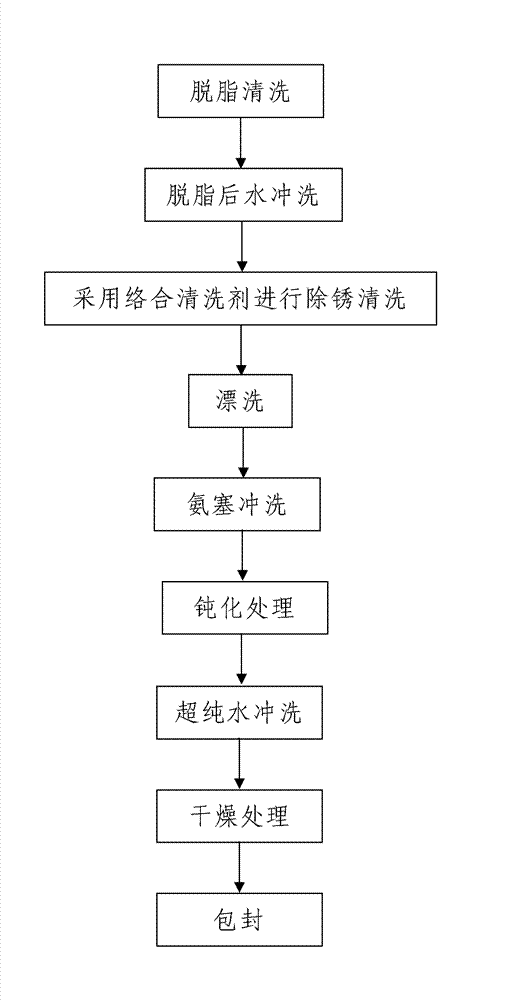

[0068] In this example, if figure 1 As shown, the polysilicon production equipment with an annual output of 1250 tons is cleaned, and the cleaning process is as follows:

[0069] Step 1, degreasing cleaning, the degreasing cleaning process is as follows:

[0070] 101. Coarse degreasing cleaning: Under normal temperature, use trichlorethylene cleaning agent to clean the metal objects to be cleaned, and the cleaning time is 2 hours.

[0071] 102. Hot air drying: After rough degreasing and cleaning, use hot air drying equipment to dry the cleaned polysilicon production equipment with hot air at a temperature of 40°C.

[0072] And after drying the cleaned polysilicon production equipment, it is necessary to use oil-absorbing filter paper to detect whether there is oil stain on the inner surface of the cleaned polysilicon production equipment: when it is detected that there is no oil stain on the inner surface, go to step 103; otherwise, go to step 103; Enter step 101, repeat rou...

Embodiment 2

[0089]In this embodiment, the polysilicon production equipment with an annual output of 3,000 tons is cleaned. The cleaning process is different from that in Example 1: when performing rough degreasing cleaning in step 101, the cleaning time is 3 hours; in step 102, hot air drying is used. Dry equipment with hot air at a temperature of 50°C to dry the polysilicon production equipment to be cleaned; in step 103, use fatty alcohol polyoxyethylene ether solution and wash at a temperature of 50°C for 3 hours; in step 3, use B Sodium diamine tetraacetate solution and rust removal and cleaning at 50°C, the rust removal and cleaning time is 8 hours; and during the actual rust removal and cleaning process, the ethylenediamine tetramine for rust removal and cleaning is detected every 30 minutes The concentration of iron ions in the sodium acetate solution, and record the results of each test simultaneously; in step 4, use citric acid solution and rinse the cleaned polysilicon production...

Embodiment 3

[0092] In this embodiment, the polysilicon production equipment with an annual output of 500 tons is cleaned. The cleaning process is different from that in Example 1: when performing rough degreasing cleaning in step 101, the cleaning time is 2.5 hours; in step 102, hot air drying is used. The drying equipment uses hot air at 45°C to dry the cleaned polysilicon production equipment; in step 103, aliphatic alcohol polyoxyethylene ether solution is used for cleaning at a temperature of 45°C, and the cleaning time is 4 hours; in step 3, B Sodium diamine tetraacetate solution and rust removal and cleaning are carried out at 45°C, and the rust removal and cleaning time is 9 hours; and during the actual rust removal and cleaning process, the ethylenediaminetetrafluoroethylene for rust removal and cleaning is detected every 40 minutes. The concentration of iron ions in the sodium acetate solution, and record the results of each test simultaneously; in step 4, use citric acid solution...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com