Mounting structure and process for improving mounting performance of building photovoltaic integrated roof

An installation structure, photovoltaic technology, applied in the support structure of photovoltaic modules, photovoltaic modules, photovoltaic power generation and other directions, can solve the problems of the impact of the strength and stability of the roof system, the stability and uniformity of the connection between the fixture and the roof panel, etc. Achieve the effect of saving reserved installation space, improving wind resistance and eliminating operating errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

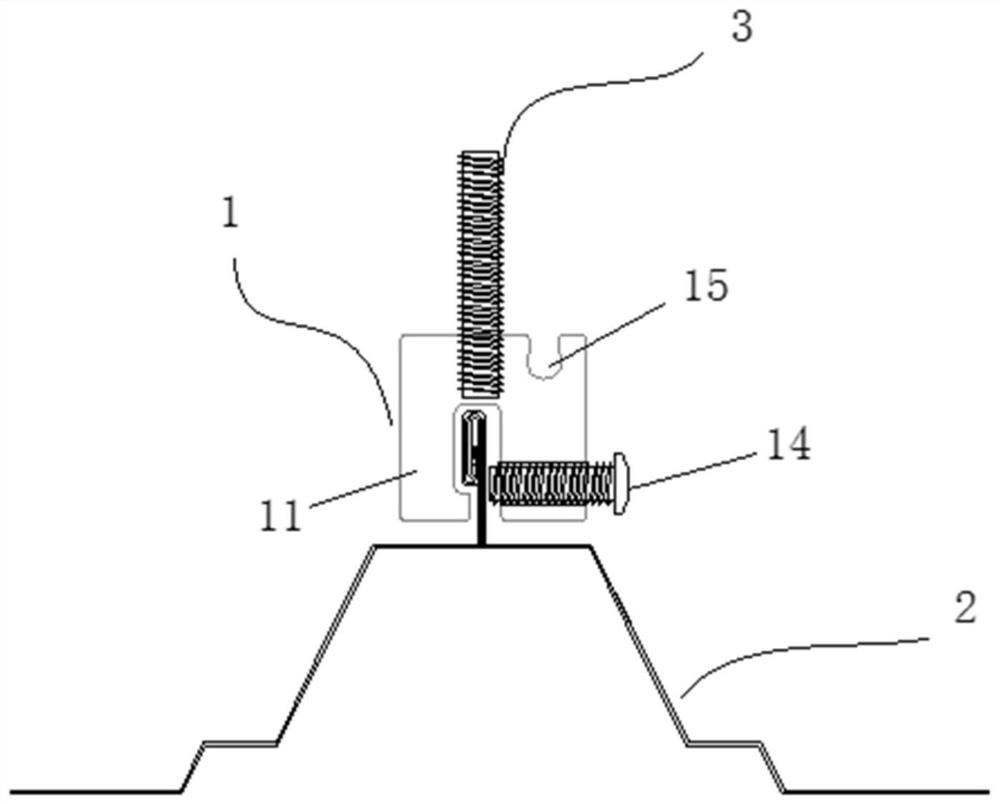

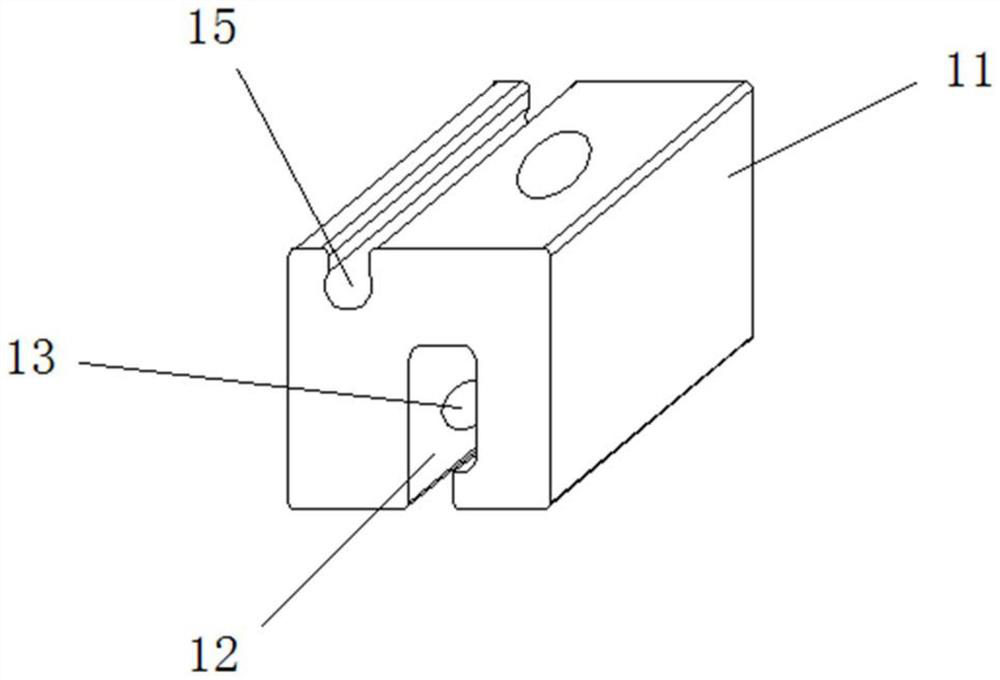

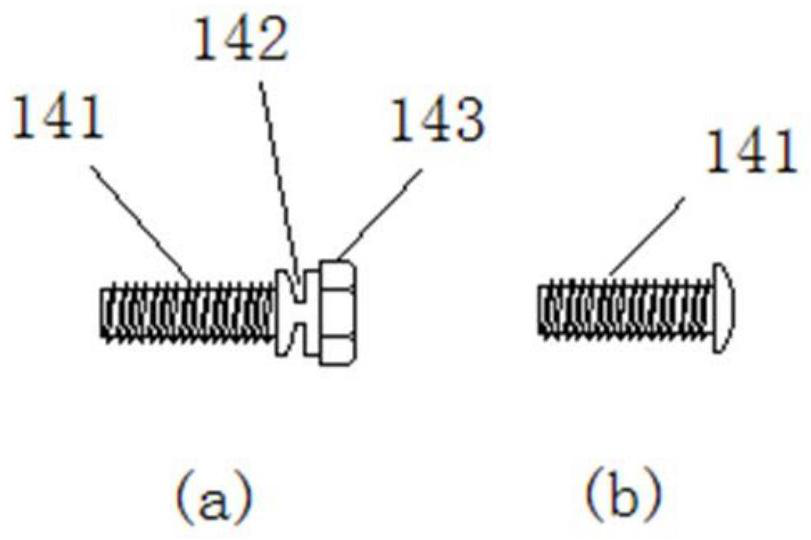

[0039] In order to ensure the uniformity and reliability of the connection strength between the installation fixture 1 and the roof panel 2 in the installation structure, and further improve the installation performance of the building photovoltaic integrated roof, this embodiment provides an installation structure that improves the installation performance of the building photovoltaic integrated roof , whose structure see Figure 1 to Figure 3 As shown, it includes the roof panel 2, the installation fixture 1 and the solar photovoltaic panel, the male rib end and the female rib end of two adjacent roof panels 2 are occluded and connected, and the installation fixture 1 is fixed on the occlusal connection part of the two adjacent roof panels 2 , the installation fixture 1 includes a fixture body 11, the lower surface of the fixture body 11 is concaved to form a fixture slot 12 for snapping into the occlusal connection part, and the side wall of the fixture body 11 is also proce...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com