Online automatic crushing and collecting device for paper cups

A collection device and automatic technology, applied in transportation and packaging, chemical instruments and methods, and solid waste removal, etc., can solve the problems of low crushing efficiency, high labor consumption, etc., saving labor, reducing replacement frequency, and reducing waste Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

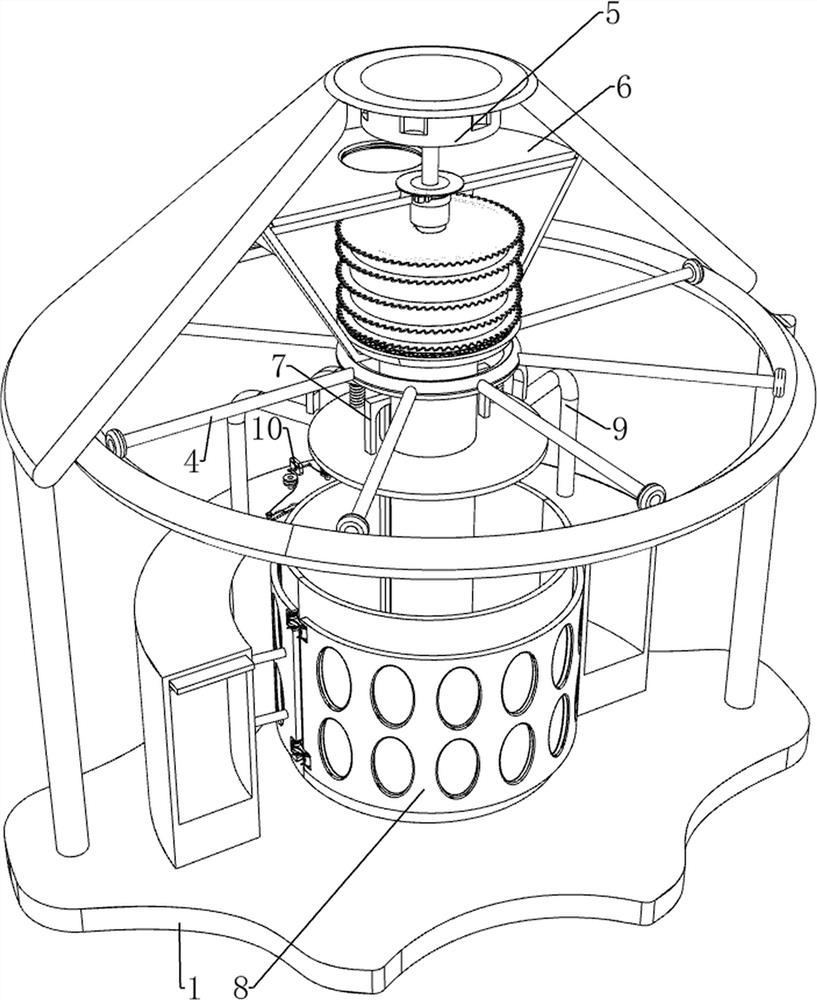

[0034] A paper cup online automatic crushing collection device, such as Figure 1-Figure 5 As shown, it includes a support frame 1, a protective cover 2, a charging barrel 3, a support rod 4, a crushing mechanism 5 and a feeding mechanism 6, the top of the support frame 1 is connected with the protective cover 2, and the middle of the upper part of the support frame 1 is connected with a device The bucket 3 and the inner lower side of the protective cover 2 are connected with eight supporting rods 4 along the circumferential direction, the inside of the protective cover 2 is connected with a crushing mechanism 5, and the top of the crushing mechanism 5 is connected with a feeding mechanism 6.

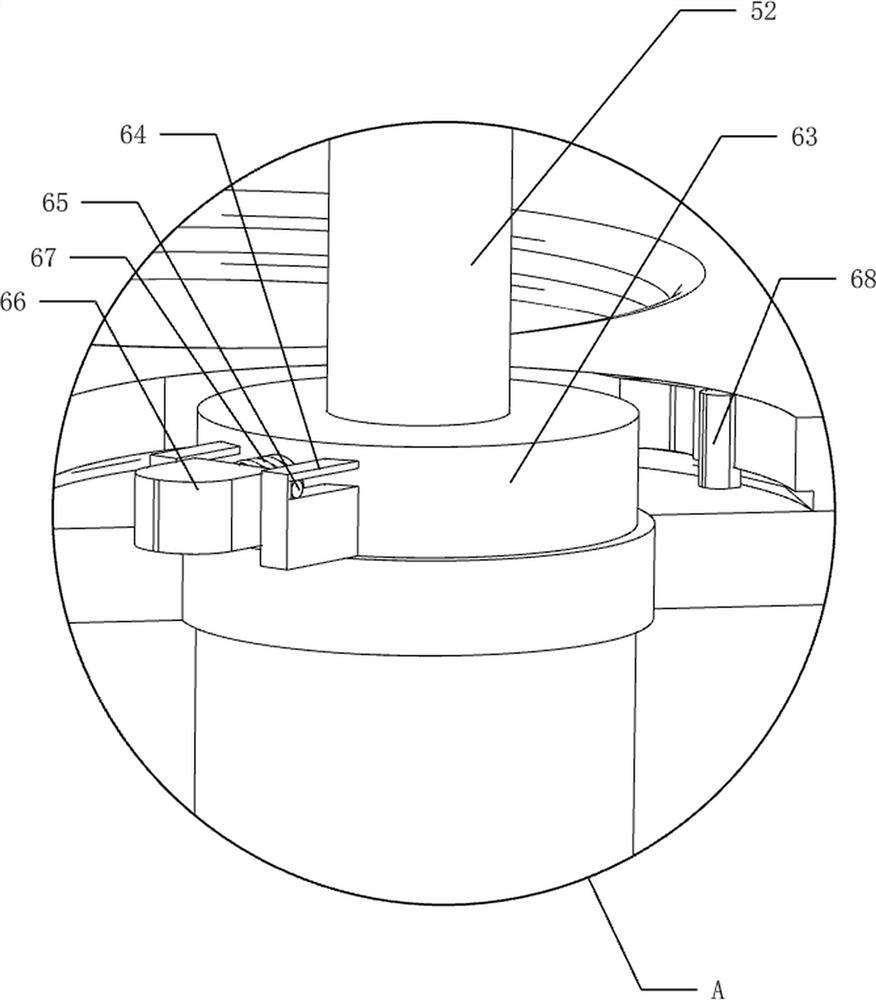

[0035] The crushing mechanism 5 includes a motor 51, a first rotating shaft 52, a cutting saw blade 53, a filter plate 54 and a crushing frame 55, the upper side of the protective cover 2 is equipped with a motor 51, and the output shaft of the motor 51 is connected with the first rotati...

Embodiment 2

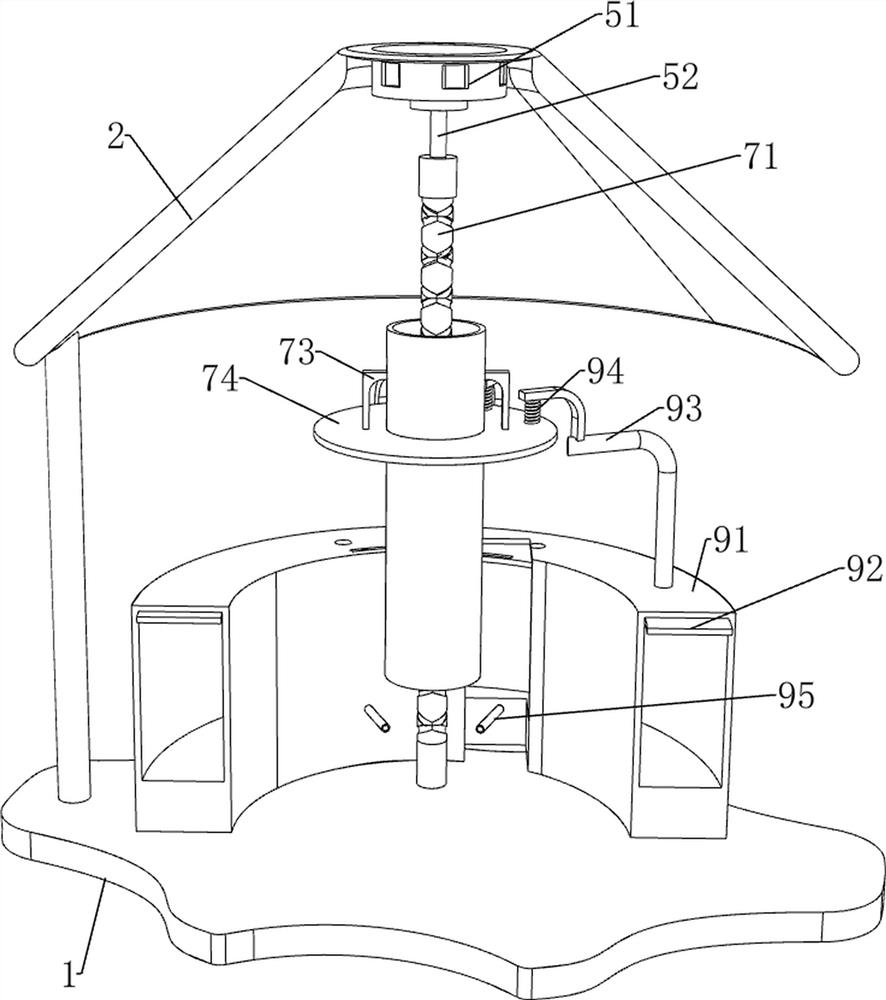

[0039] On the basis of Example 1, such as figure 1 with Figure 6 As shown, an extruding mechanism 7 is also included. The extruding mechanism 7 includes a two-way screw rod 71, a limit barrel 72, a pressing rod 73 and a first pressing plate 74. The bottom of the first rotating shaft 52 is connected with a two-way screw rod 71, and the filter plate 54 bottoms are connected with a limit barrel 72 in the middle, and the middle part of the two-way screw mandrel 71 is threadedly connected with a pressure rod 73 , and the bottom of the pressure rod 73 is connected with a first pressure plate 74 .

[0040] When the first rotating shaft 52 rotates, it will drive the two-way screw rod 71 to rotate. The rotation of the two-way screw rod 71 will drive the pressure rod 73 to move downward. The downward movement of the pressure rod 73 will drive the first pressure plate 74 to move downward. The shredded paper cups are compacted.

Embodiment 3

[0042] On the basis of Example 2, such as figure 1 , Figure 7 with Figure 8As shown, a clamping mechanism 8 is also included. The clamping mechanism 8 includes a splint 81, a third rotating shaft 82, a connecting block 83 and a torsion spring 84. The upper and lower sides of the left part are rotatably connected with a third rotating shaft 82, and the third rotating shaft 82 on the upper and lower sides is connected with a connecting block 83, and a torsion spring 84 is connected between the connecting block 83 and the adjacent splint 81.

[0043] Before using this device, people can fix the splint 81 on the rear side through props. When people need to collect the crushed paper cups in the charging bucket 3, they can manually grab the splint 81 on the front side and turn it forward. , the splint 81 rotates and opens to drive the connecting block 83 to rotate, the connecting block 83 rotates to compress the torsion spring 84, and the splint 81 rotates to open to cancel the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com