Differential speed and variable speed integrated power assembly special for pure electric drive loading vehicle

A pure electric drive and powertrain technology, which is applied to electric power units, power units, control units, etc., can solve the problems of inability to drive, poor feasibility, inconsistent driving speed, etc., and achieve the effect of high cost performance and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

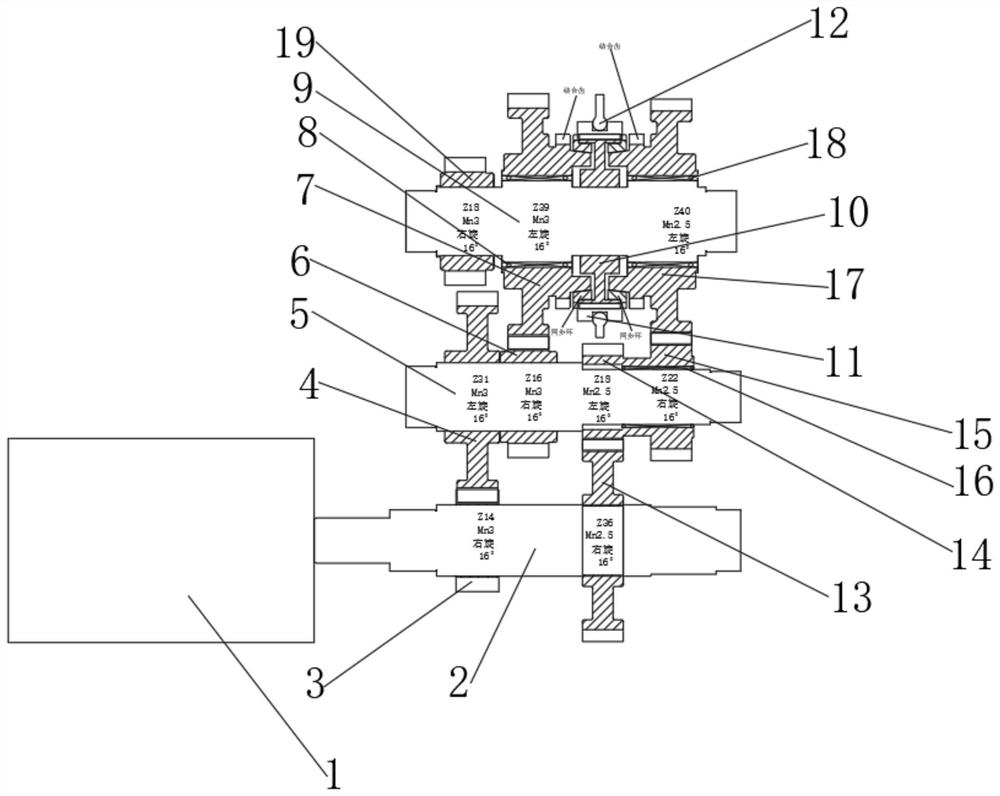

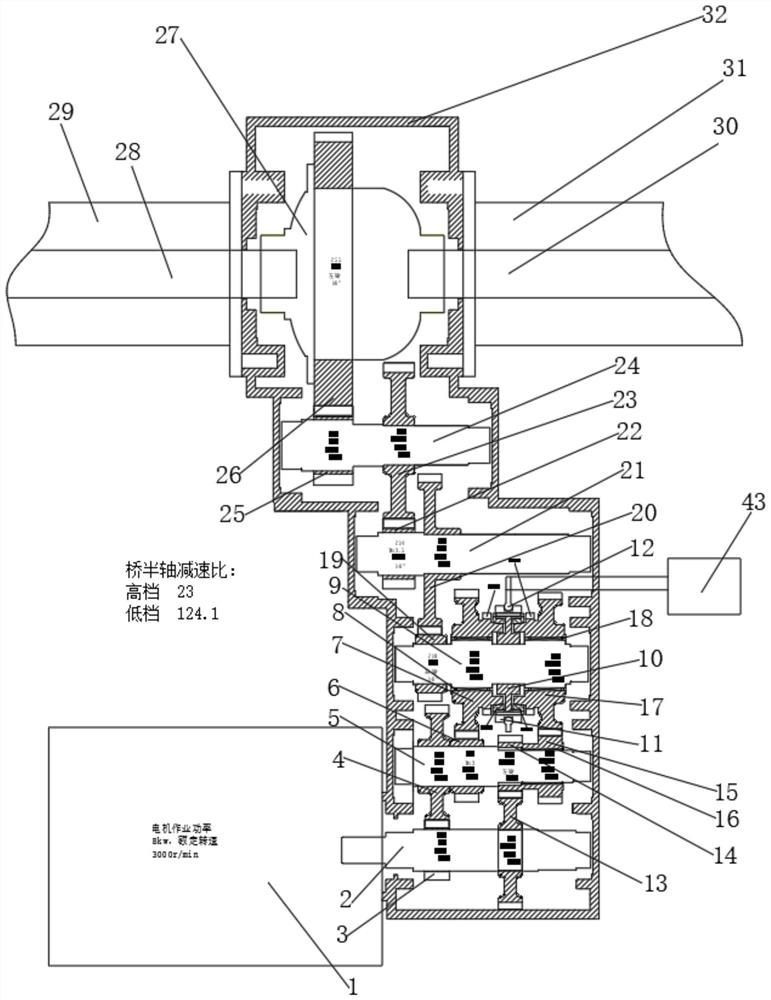

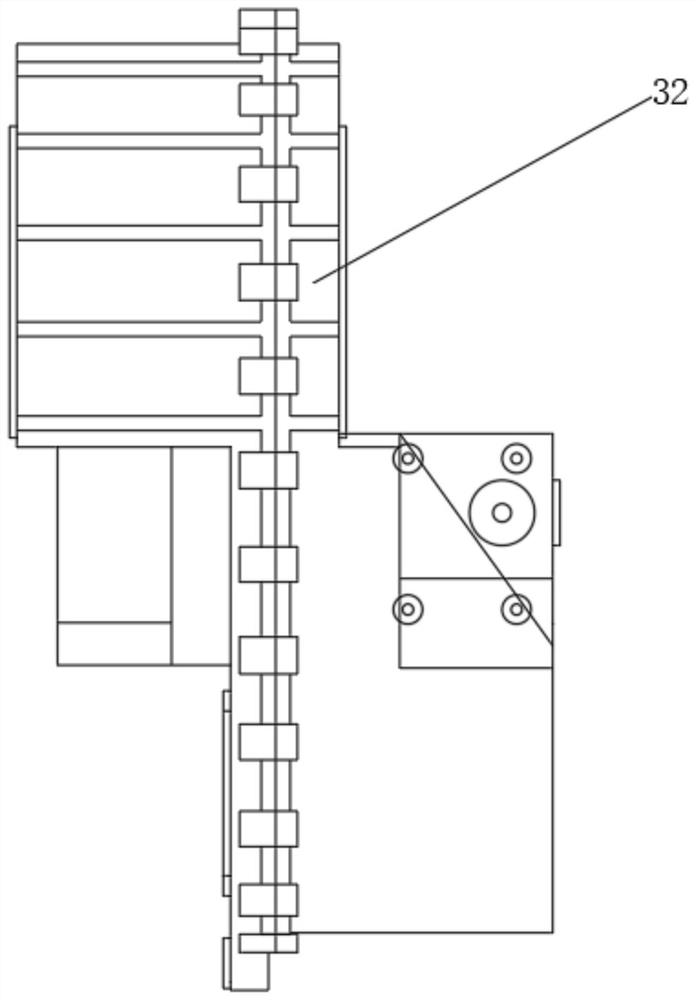

[0037] The components of the specific implementation of the powertrain are found Figure 2 , Figure 5 , Figure 6 , the part name is the same as above.

[0038] Specific implementation plan: first look at the difference of the powertrain, the transmission of the integrated gearbox, three-dimensional shape see Figure 4 , the transmission scheme and gear parameters in the box body can be found Figure 2 。

[0039]Low gear: Wheel drive motor 1 output power to the motor power input shaft 2, motor power input shaft 2 and the first active gear 3 (14 teeth Mn3 right rotation 16 °) coupling connection, driving the first active gear 3 rotation, the first active gear 3 and the first transmission gear 4 (31 teeth Mn3 left rotation 16 °) mesh, driving the first transmission gear 4 rotation, the first transmission gear 4 and the first transmission shaft 5 coupling connection, so that the first transmission shaft 5 rotation to achieve a first level of deceleration, the reduction ratio of 2.21. Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com