Method for obtaining 1, 3-diglyceride from high oleic acid sunflower seed oil

A technology for sunflower oil and diglyceride, applied in the field of obtaining 1,3-diglyceride, can solve the problem of long reaction time, undisclosed enzymatic hydrolysis of sunflower oil and its enzymatic hydrolysis products, and inability to determine whether all glycerol diols From other problems, to achieve the effect of simple operation steps and improving the efficiency of enzymatic hydrolysis

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1A1-A5

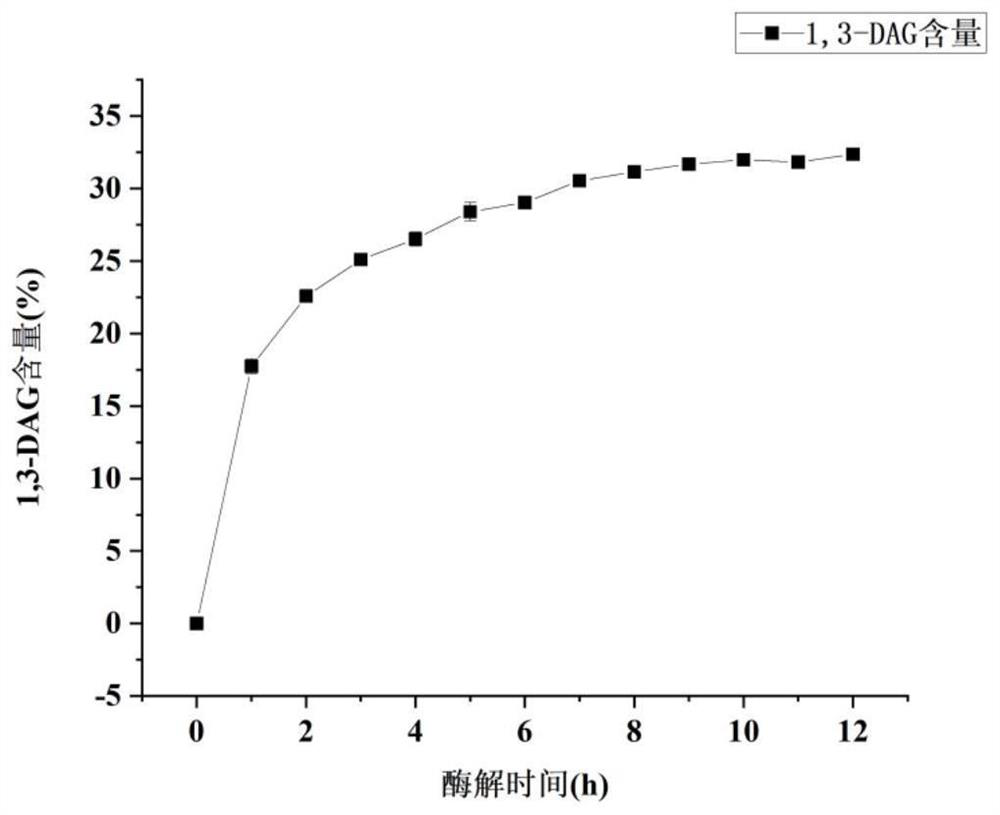

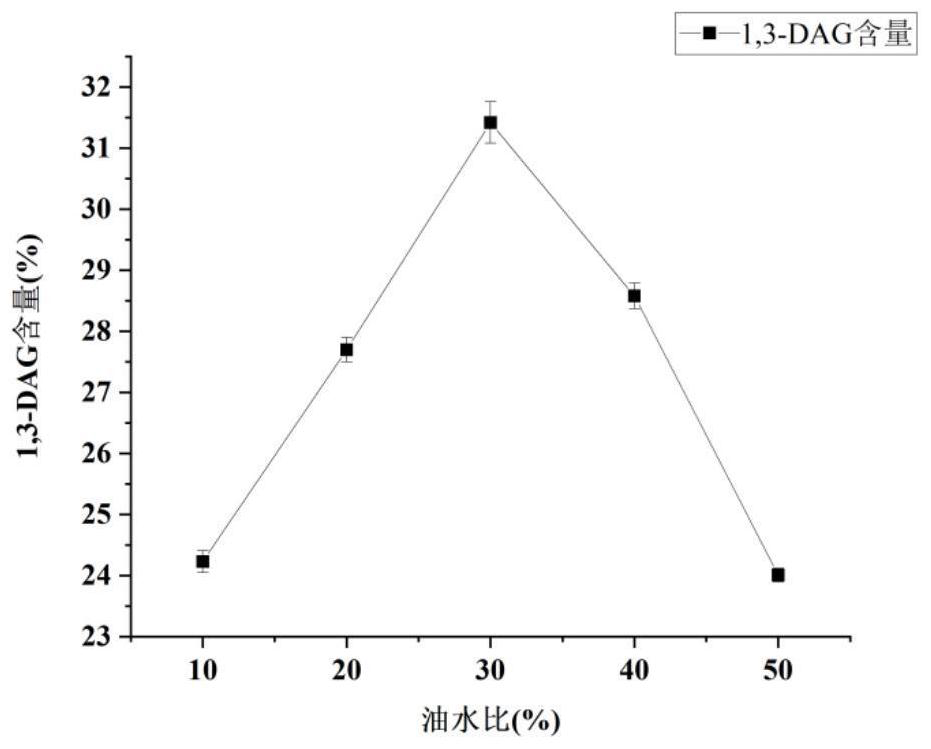

[0038] Embodiment 1A1-A5 focuses on the impact of deionized water with different oil-water ratios on the content of the final product 1,3-diglyceride. The specific scheme is as follows:

[0039] The method for obtaining 1,3-diglyceride from high oleic sunflower oil comprises the following steps:

[0040] (1) Enzymolysis: Accurately weigh 5g of high oleic sunflower oil, add 3000u / g Candida antarctica lipase A based on the weight of high oleic sunflower oil, and then add deionized water with different oil-water ratios (specifically See Table 1), put it in a constant temperature water bath shaker, and react at 70°C at a speed of 250r / min for 9h. After the reaction, centrifuge the product at 3000r / min for 10min, and take the supernatant to detect 1,3-DAG ( 1,3-diglyceride) content.

[0041] Table 1 Effect of different oil-water ratio (%) treatments on 1,3-DAG content

[0042]

[0043] (2) Molecular distillation: Pour 50mL of centrifuged enzymatic hydrolyzate supernatant into ...

Embodiment 1B1-B5

[0056] Embodiment 1B1-B5 focuses on the impact of water bath oscillation at different temperatures on the content of the final product 1,3-diglyceride, and the specific scheme is as follows:

[0057] The method for obtaining 1,3-diglyceride from high oleic sunflower oil comprises the following steps:

[0058] (1) Enzymolysis: Accurately weigh 7g of high oleic sunflower oil, based on the weight of high oleic sunflower oil, add 3000u / g Candida antarctica lipase A, and then add 30% deionized water was placed in a constant temperature water bath oscillator, and reacted at a speed of 250r / min for 9h under different temperature conditions (see Table 3 for details). After the reaction, the product was centrifuged at 3000r / min for 10min, and the supernatant was taken Liquid detection of 1,3-DAG (1,3-diglyceride) content.

[0059] Table 3 The effect of water bath shaking treatment at different temperatures (°C) on the content of 1,3-DAG

[0060]

[0061] (2) Molecular distillation...

Embodiment 1C1-C5

[0065] Embodiment 1C1-C5 focuses on the impact of different enzyme additions on the content of the final product 1,3-diglyceride, and the specific scheme is as follows:

[0066] The method for obtaining 1,3-diglyceride from high oleic sunflower oil comprises the following steps:

[0067] (1) Enzymolysis experiment: Accurately weigh 11 g of high oleic sunflower oil, based on the weight of high oleic sunflower oil, add different contents of Candida antarctica lipase A (see Table 4 for details), and then add High oleic sunflower oil weighs 30% deionized water, put it in a constant temperature water bath shaker, and react at a speed of 250r / min for 9h at 70°C. After the reaction, centrifuge the product at 3000r / min for 10min, and take the supernatant Liquid detection of 1,3-DAG (1,3-diglyceride) content.

[0068] Table 4 Effects of different enzyme dosage (u / g) treatments on 1,3-DAG content

[0069]

[0070] (2) Molecular distillation: Pour 50mL of centrifuged enzymatic hydro...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap