Mining machinery damping supporting device

A technology of mechanical shock absorption and support devices, which is applied in the direction of mechanical equipment, springs/shock absorbers, supporting machines, etc., can solve problems such as unsatisfactory shock absorption effects, imperfect shock absorption measures, and inability to adjust heights, etc., to achieve Improve the vibration filtering effect, enhance the anti-instability ability, and reduce the effect of vibration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

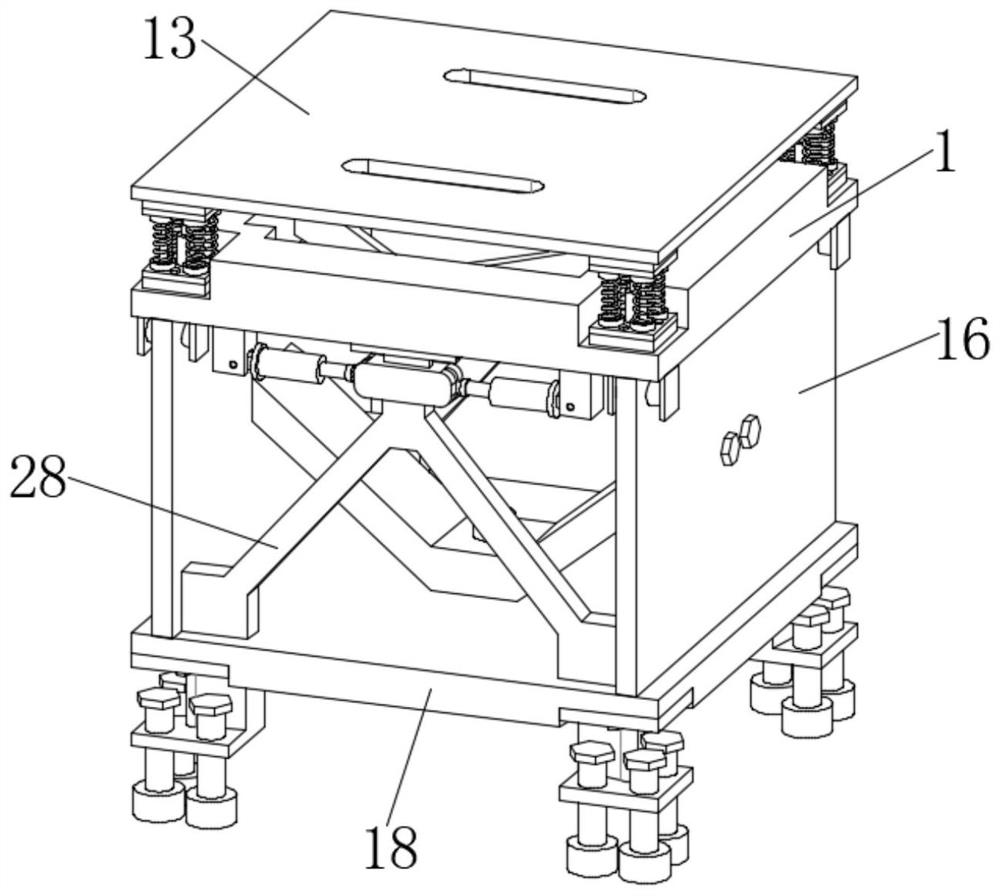

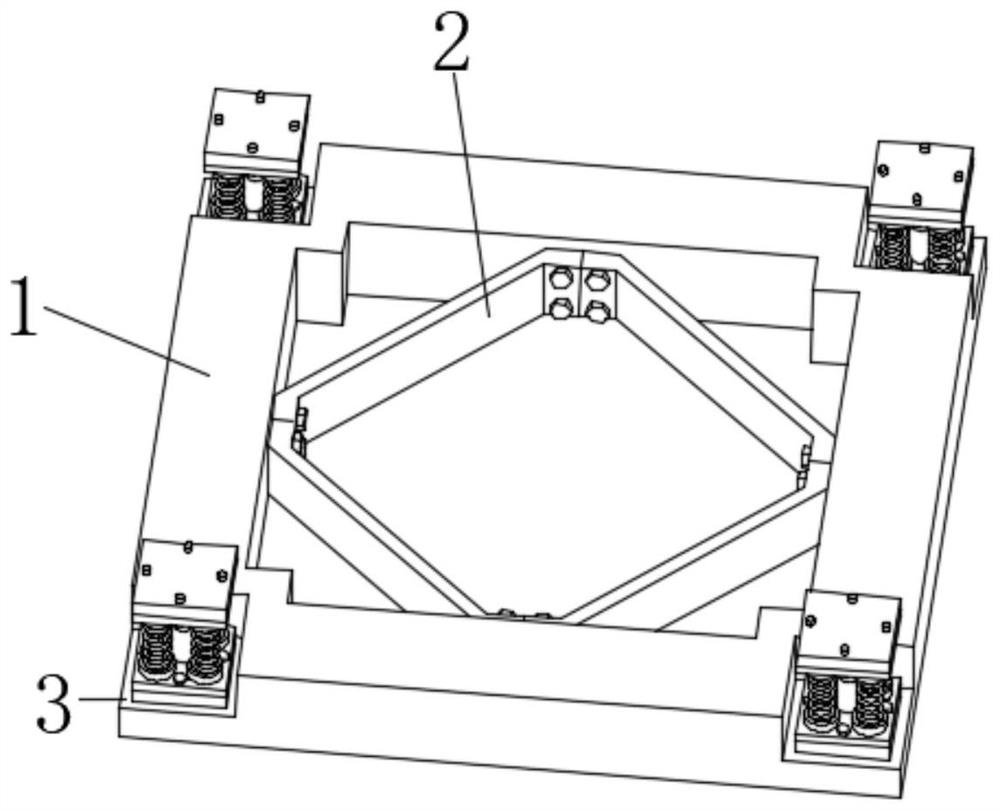

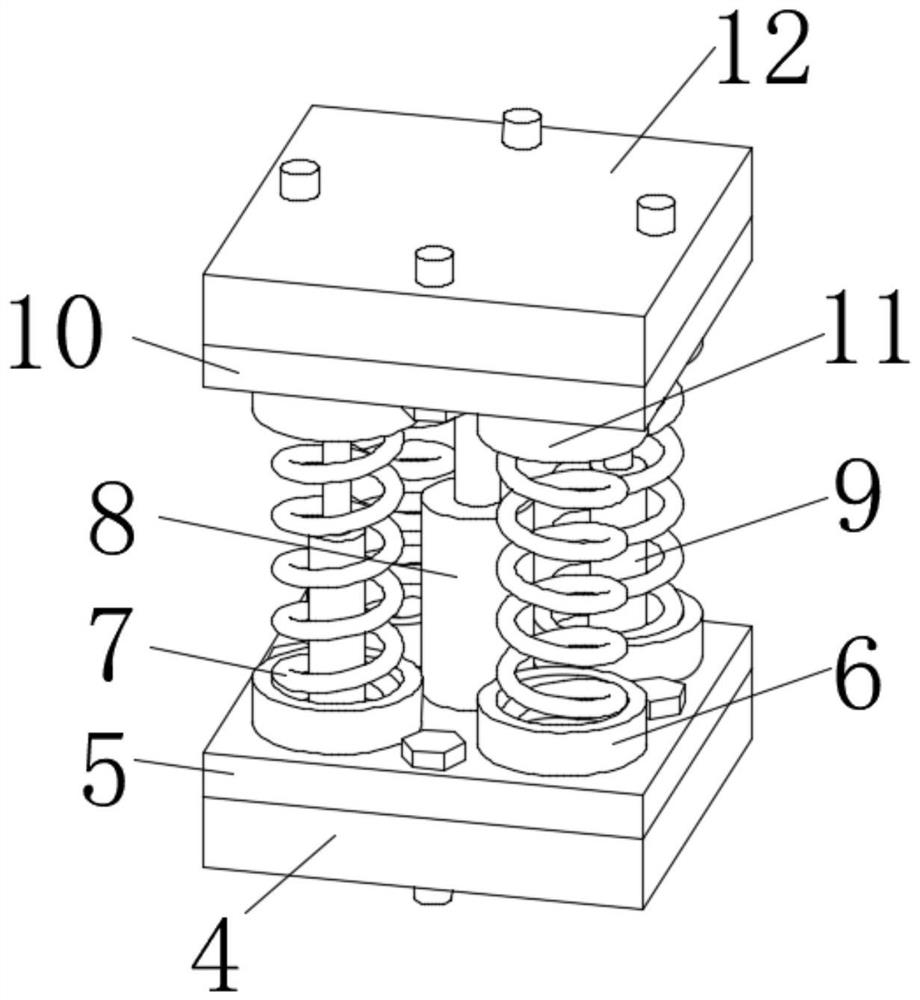

[0029] see Figure 1-8, a mining machinery shock absorbing supporting device, including installing a main frame 1, the installation main frame 1 is arranged in a rectangular frame shape, the four corners of the upper surface of the installation main frame 1 are provided with a rectangular groove-3, and the groove bottom of the rectangular groove-3 The surface is provided with a cushioning rubber pad-4, and the upper surface of the cushioning rubber pad-4 is provided with a mounting base plate 5, and the center of the mounting base plate 5 upper surface is fixedly connected with a central shock absorber 8, and the top of the central shock absorber 8 is fixed. Connected with the installation top plate 10, the upper surface of the installation top plate 10 is provided with cushioning rubber pad 2 12, the top of the installation main frame 1 is provided with a mounting seat 13, the surface of the mounting seat 13 is provided with an installation groove, and the bottom of the instal...

Embodiment 2

[0031] Based on Example 1, such as Figure 1-8 , including the installation of the main frame 1, the installation of the main frame 1 is a rectangular frame-like setting, the four corners of the upper surface of the installation main frame 1 are provided with a rectangular groove-3, and the bottom surface of the rectangular groove-3 is provided with a cushioning rubber pad-4 , the upper surface of cushioning rubber pad one 4 is provided with installation bottom plate 5, and the center of installation bottom plate 5 upper surface is fixedly connected with center shock absorber 8, and the top of center shock absorber 8 is fixedly connected with installation top plate 10, and installation top plate 10 The upper surface of the upper surface is provided with cushioning rubber pad 2 12, the top of the installation main frame 1 is provided with a mounting seat 13, the surface of the mounting seat 13 is provided with an installation groove, and the bottom of the installation main frame...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com