Injection molding method for producing plastic box having integrated inspection window, plastic box and power tool comprising such plastic box

A technology for power tools and inspection windows, which is applied in the field of power tools and can solve problems such as limiting the visibility of fuel liquid levels

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

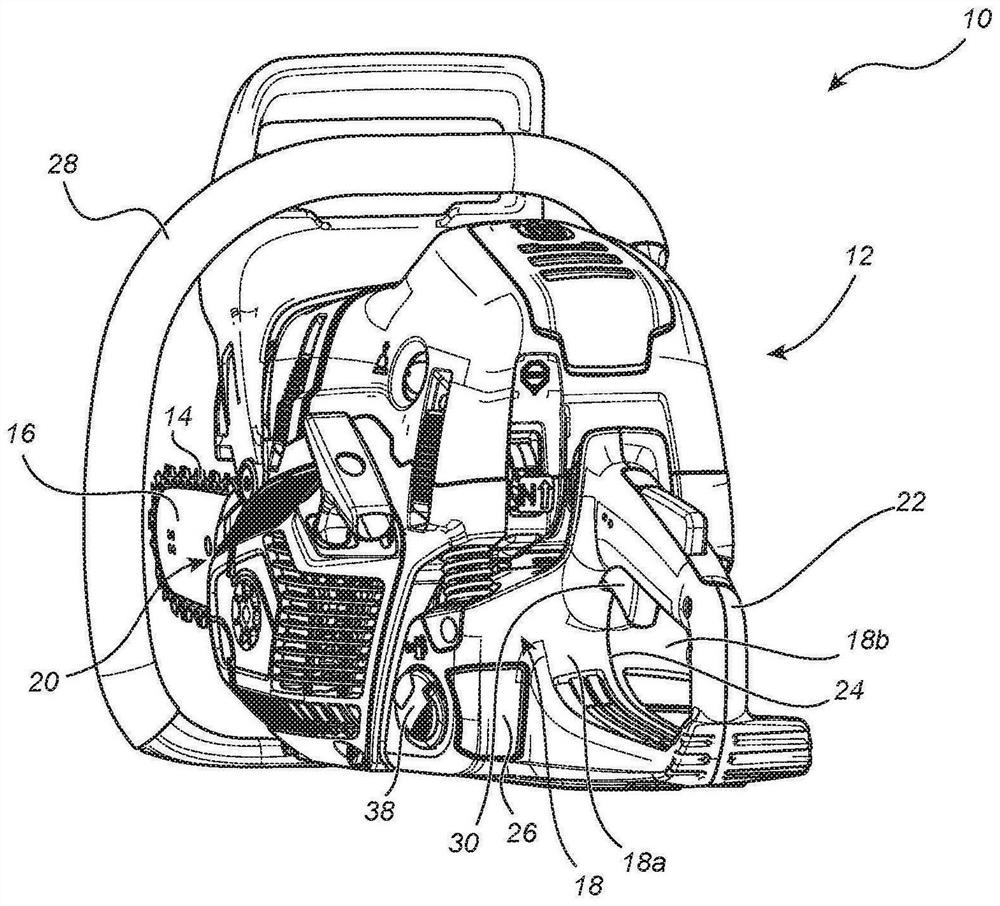

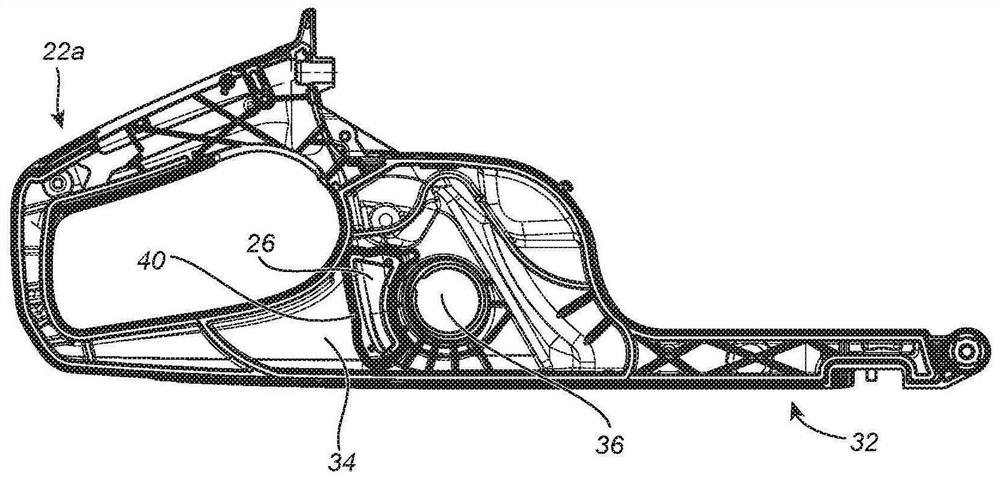

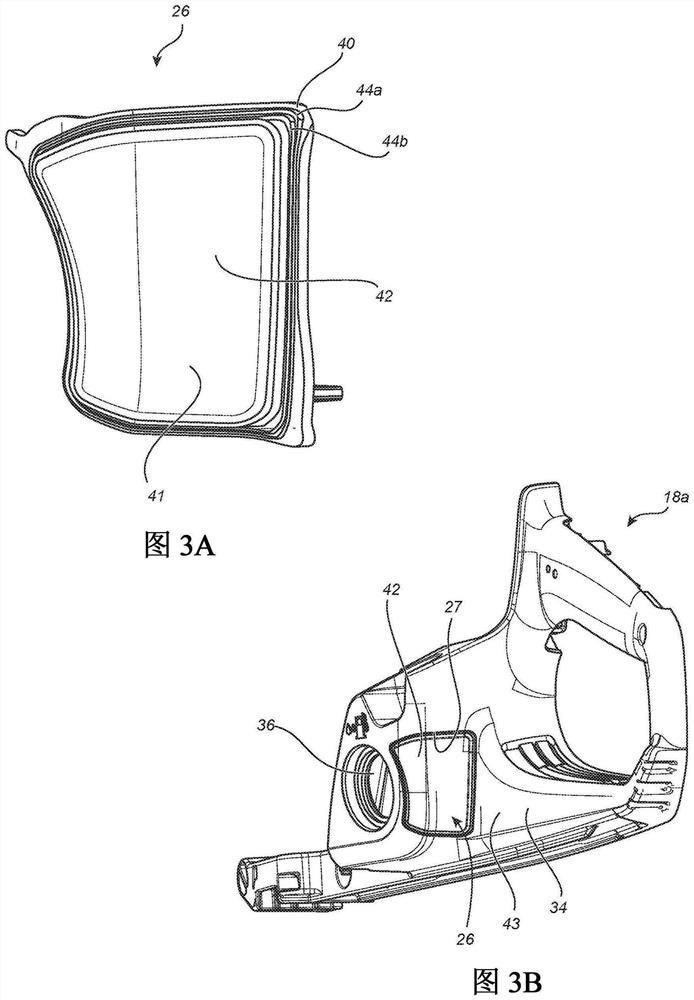

[0051] figure 1 A power tool embodied as a hand-held chainsaw 10 is shown. Chainsaw 10 includes an internal combustion engine 12 configured to rotate a saw chain 14 about a guide bar 16 . The fuel tank 18 of the chainsaw 10 is configured to hold fuel to be burned in the internal combustion engine 12 (which is typically a two-stroke engine), and the chain oil tank 20 is configured to hold saw chain oil for use as the saw chain 14 travels along the guide bar 16 Lubricate the saw chain. The fuel tank 18 is integrally formed with the rear handle 22 of the chainsaw 10 and includes two opaque plastic tank halves 18 a , 18 b fused together along a joint 24 . A first of the tank halves 18a, 18b 18a is provided with a transparent fuel inspection window 26 integrally formed with this tank half 18a in a manner which will be described in more detail below. The chainsaw 10 also includes a front handle 28 and the rear handle 22 is provided with a trigger 30 for controlling the internal c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Wall thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com