Recycling structure for treating sewage produced by spraying

A sewage recycling and filter plate technology, applied in separation methods, filtration separation, chemical instruments and methods, etc., can solve the problems of affecting work efficiency, increasing costs, water waste, etc., achieving the effect of novel structure, reduced waste, and easy cleaning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

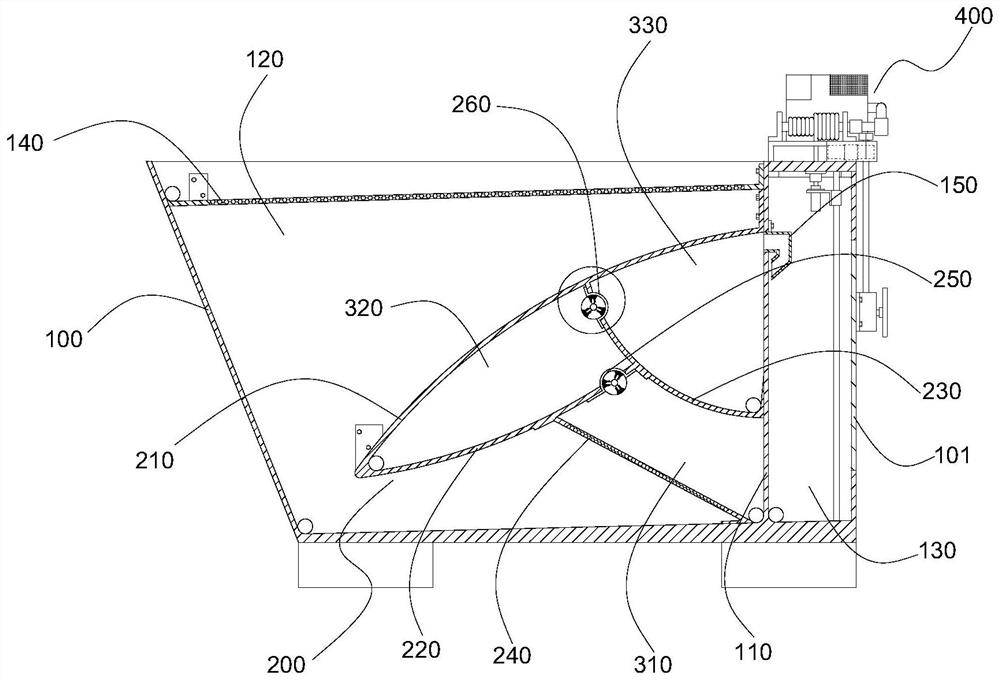

[0031] Such as Figure 1 to Figure 6 As shown, a specific embodiment of the present invention discloses a recycling structure for treating spray-painted sewage, which includes a box body 100 with an open top, and a vertical partition 110 is fixed inside the box body 100. The partition 110 is divided into a filter area 120 and a recovery area 130, which can facilitate partition cleaning;

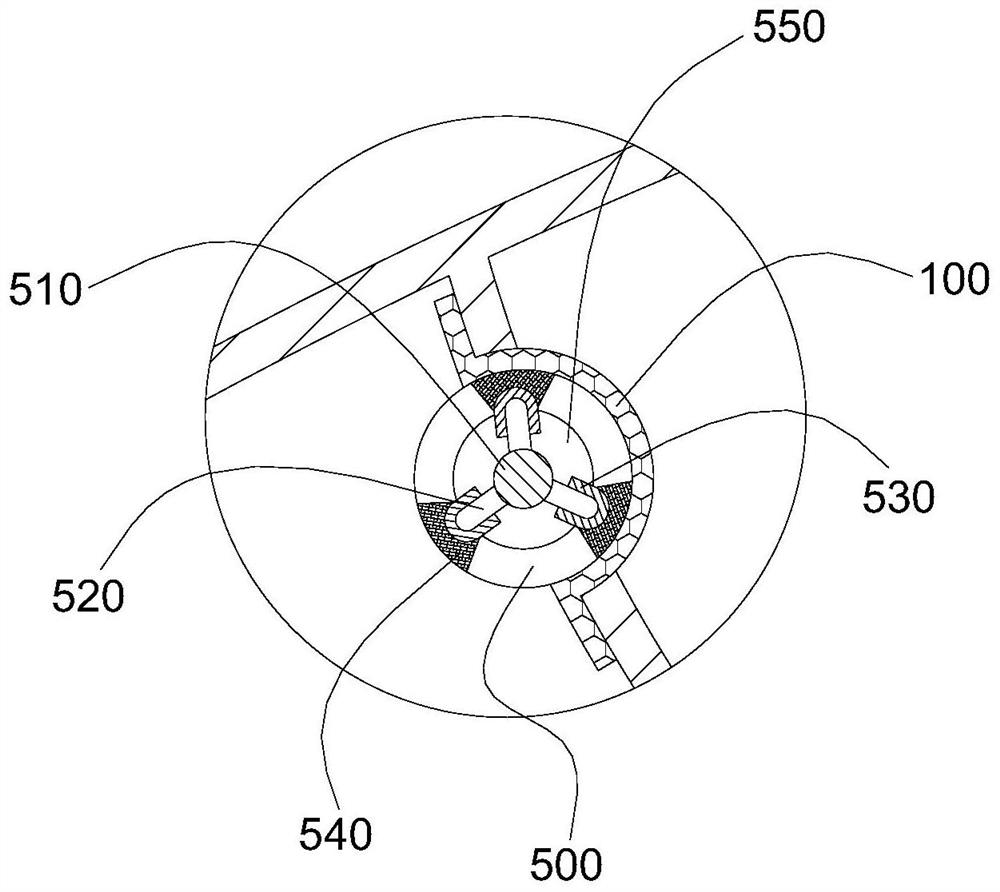

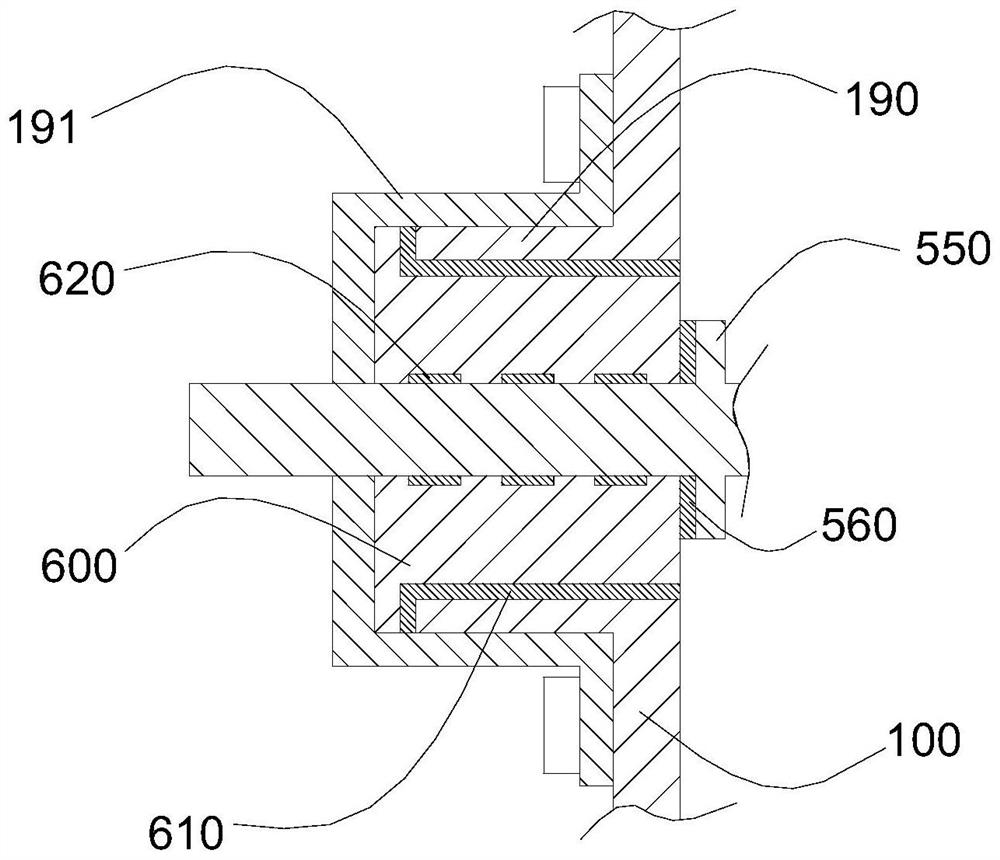

[0032] A first filter plate 140 is installed on the top of the filter area 120, which can be used to filter large particles of impurities. A partition 200 is provided below the first filter plate 140, and the inside of the partition 200 is divided into first filter chambers distributed sequentially from bottom to top. 310, the second filter cavity 320, the third filter cavity 330, the bottom of the first filter ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com