Catalyst carrier, hydrogenation catalyst and heavy distillate oil hydro-upgrading method

A hydrogenation catalyst and carrier technology, applied in catalyst carriers, chemical instruments and methods, molecular sieve catalysts, etc., can solve the problems of little necessity and too much, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

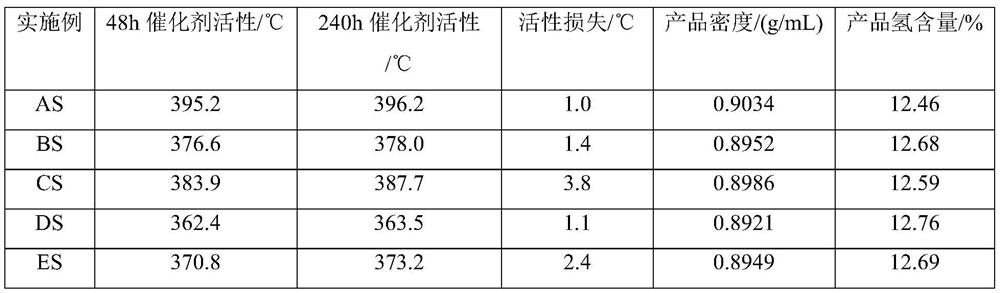

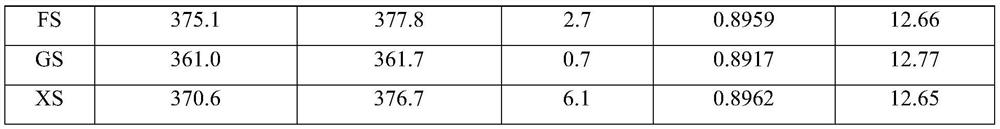

Examples

preparation example Construction

[0032] A second aspect of the present invention provides a method for preparing a carrier for a hydrogenation catalyst, the preparation method comprising:

[0033] S1, mixing pseudo-boehmite, amorphous silica-alumina oxide, beta-type molecular sieve, carboxymethyl cellulose and squash powder to obtain a mixed powder;

[0034] S2. Mix the mixed powder with water, knead and extrude to obtain extruded strips;

[0035] S3. Performing first drying and first roasting on the extruded strip.

[0036] According to the second aspect of the present invention, in step S1, the weight of the pseudo-boehmite, the amorphous silica-alumina oxide, the beta-type molecular sieve, the carboxymethyl cellulose, and the kale powder The ratio can be: 10-55: 15-85: 3-35: 1.0-5.0: 2-4;

[0037] In step S2, the amount of water may be 80-140 mL per 100 g of the mixed powder.

[0038] According to the second aspect of the present invention, the characteristics of the pseudo-boehmite may include: SiO 2 Th...

Embodiment 1

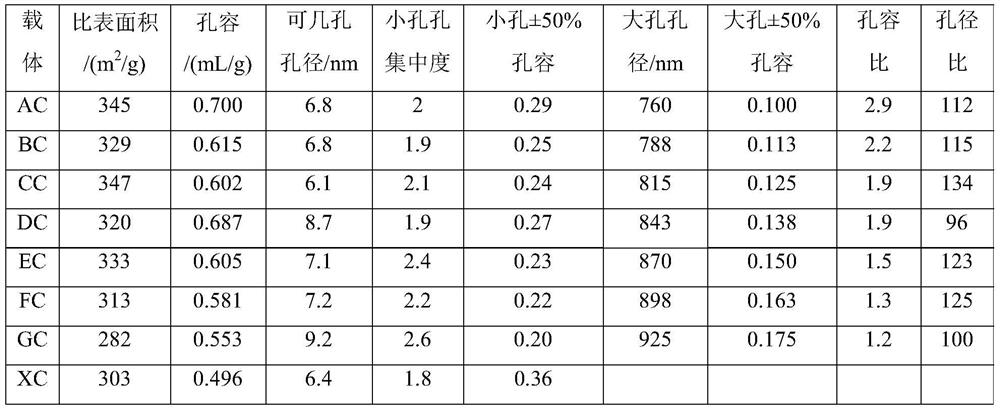

[0051] Take SD (taken from Qimao Catalyst Factory, produced by Shandong Aluminum Factory, dry basis 64.5%) 31.0g, silicon-aluminum material siral40 (taken from Catalyst Changling Branch, produced by SASOL, silicon oxide content 40.3%, dry basis 79.7%) 94.10g, beta-type molecular sieve beta-A (taken from Catalyst Changling Co., Ltd., silicon-aluminum ratio 25.8) 5.55g, carboxymethylcellulose A (M450, imported repacking) 2g, scallop powder 5g, mixed to obtain mixed powder . Take 125mL of deionized water and mix it with the mixed powder, use a small extruder to knead repeatedly 3 times, The extruded strips were obtained from the three-lobed orifice plate, and the extruded strips were dried at 120°C for 6 hours to obtain dry strips. The dry strips were taken and put into a roasting furnace, and treated at 550°C for 3 hours, keeping the air flow at 30L / h, cooled to room temperature and taken out, recorded as carrier AC.

[0052] Based on 100g of the carrier, a mixed aqueous sol...

Embodiment 2

[0054] Take SD (taken from Qimao Catalyst Factory, produced by Shandong Aluminum Factory, dry basis 64.5%) 46.5g, silicon-aluminum material siral40 (taken from Catalyst Changling Branch, produced by SASOL, silicon oxide content 40.3%, dry basis 79.7%) 69.01g, beta type molecular sieve beta-B (taken from Catalyst Changling Co., Ltd., silicon-aluminum ratio 56.3) 16.09g, carboxymethylcellulose B (Shandong Heda Co., Ltd.) 2.5g, scallop powder 5g, mixed to obtain Mix powder. Take 92mL of deionized water and mix it with the mixed powder, use a small extruder to knead repeatedly 3 times, The extruded strips were obtained from a trilobal orifice plate, and the extruded strips were dried at 115°C for 6 hours to obtain dry strips. The dry strips were taken and put into a roasting furnace, and treated at 600°C for 2.5 hours, keeping the air flow rate at 35L / h, take it out at room temperature, and record it as carrier BC.

[0055] Based on 100g of the carrier, a mixed aqueous solutio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Pore volume | aaaaa | aaaaa |

| Specific surface | aaaaa | aaaaa |

| Bulk density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com