Catalyst support, water-resistant hydrogenation catalyst and hydro-upgrading method for high-oxygen-content biomass oil

A technology of hydrogenation catalyst and carrier, which is applied in the direction of catalyst carrier, chemical instrument and method, catalyst activation/preparation, etc. It can solve the problems of inability to process sulfur-containing raw materials and low hydrogenation activity, and achieve medium cracking activity and good water resistance , The effect of high distillate oil yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0038] The second aspect of the invention provides a preparation method for preparing a support for a water-resistant hydrogenation catalyst, the preparation method comprising:

[0039] S1. Mixing pseudo boehmite, amorphous silicon aluminum oxide, compound containing sulfate and Sesbania powder to obtain mixed powder;

[0040] S2. Mixing the mixed powder with nitric acid solution, kneading and extruding to obtain an extrusion strip;

[0041] S3. The extrusion strip is subjected to the first drying and water vapor treatment.

[0042] According to the second aspect of the invention, in step S1, the weight ratio of the pseudo boehmite, the amorphous silicon aluminum oxide, the compound containing sulfate and the Sesbania powder can be 7-65:40-90:0.03-1.20:2.5-3.5:; Preferably 10-55:45-85:0.05-1.00; 2.8-3.2; In step S2, the amount of the nitric acid solution can be 120-225 ml per 100 g of the mixed powder.

[0043] According to the second aspect of the invention, the characteristics o...

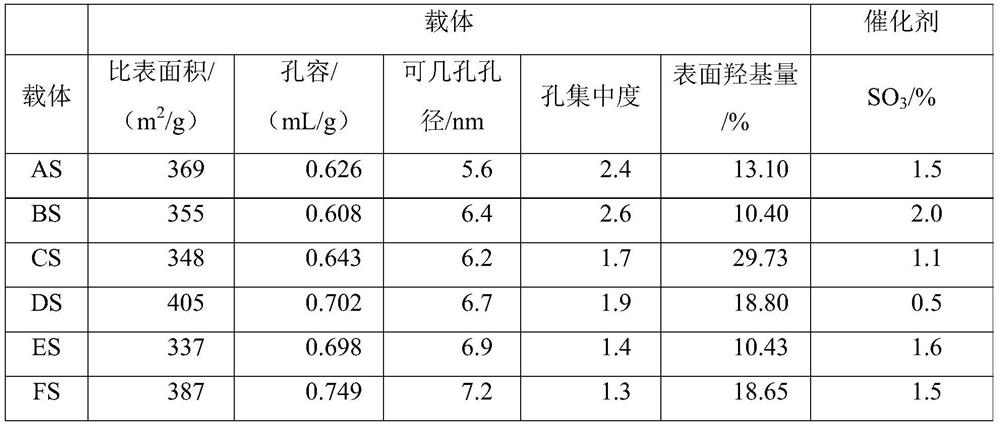

Embodiment 1

[0057] 60g of sb powder (produced by Sasol company, 74.5% dry basis), 140g of siral 30 powder (produced by Sasol company, 79.1% dry basis), 9g of ammonium sulfate and 6G of Sesbania powder are mixed to obtain the mixed powder. 5.5mL concentrated nitric acid, add water to 165ml, and stir at room temperature for 5 minutes. Mix the nitric acid solution with the mixed powder, and use a small strip extruder to knead it repeatedly for 3 times The cylindrical orifice plate is used to obtain the extrusion strip. The extrusion strip is dried at 120 ℃ for 6 hours. Take 100g of the dry strip and put it into the water vapor treatment furnace. Keep the air flow at 125L / h and the water flow of the liquid injection pump at 0.42ml / min. Treat it at 600 ℃ for 3 hours, cool it to about 400 ℃, stop the air inlet and water inlet, reduce it to room temperature, take it out and record it as carrier as.

[0058] The mixed aqueous solution of nickel nitrate and ammonium metatungstate (purchased from Ch...

Embodiment 2

[0060] 80g sb powder (produced by Sasol company, 74.5% dry basis), 140g siral 40 powder (produced by Sasol company, 79.6% dry basis), 12g ammonium sulfate and 6G Sesbania powder are mixed to obtain the mixed powder. Add 5.5mL concentrated nitric acid to 180ml and stir at room temperature for 5 minutes. Mix the nitric acid solution with the mixed powder, and use a small strip extruder to knead it repeatedly for 3 times The cylindrical orifice plate is used to obtain the extrusion strip. The extrusion strip is dried at 120 ℃ for 6 hours. Take 100g of the dry strip and put it into the water vapor treatment furnace. Keep the air flow at 25L / h and the water flow of the liquid injection pump at 0ml / min. treat it at 700 ℃ for 2 hours, cool it to about 400 ℃, stop air inlet and water inlet, take it out at room temperature and record it as the carrier BS.

[0061] The mixed aqueous solution of nickel nitrate and ammonium metatungstate (purchased from Changling catalyst plant) is prepa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Pore volume | aaaaa | aaaaa |

| Specific surface | aaaaa | aaaaa |

| Bulk density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com