Relaxation ferroelectric lead-based ceramic material with high phase change temperature, excellent fatigue resistance and high electromechanical performance, and preparation method and application thereof

A technology of phase transition temperature and fatigue resistance, which is applied in the field of preparation and application of relaxor ferroelectric lead-based ceramic materials with high phase transition temperature, excellent fatigue resistance and high electromechanical performance, and can solve the problem of poor electrical fatigue resistance , can not take into account the problems of high electromechanical performance, high phase transition temperature, excellent fatigue resistance, low phase transition temperature, etc., to achieve the effect of improving the quality of directional texture, excellent fatigue resistance, and high phase transition temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

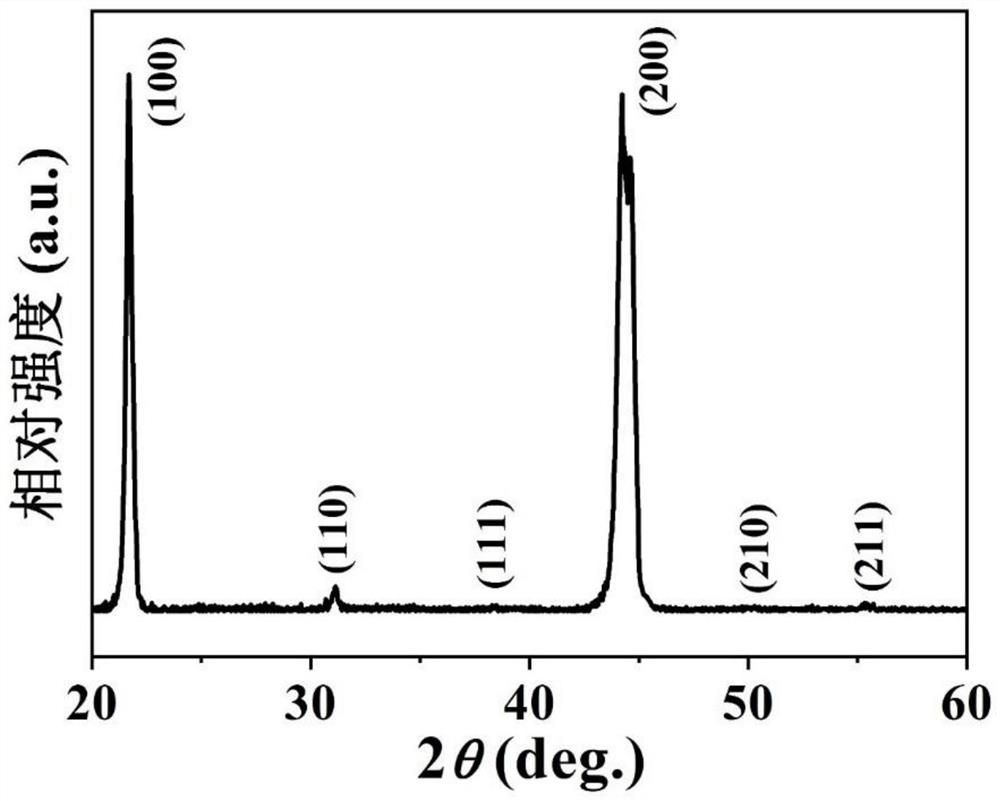

[0029] Specific Embodiment 1: This embodiment is a relaxor ferroelectric lead-based ceramic material with high phase transition temperature, excellent fatigue resistance and high electromechanical properties. Its general chemical formula is (1-x-y)Pb(A,Nb)O 3 -xPbZrO 3 -yPbTiO 3 -awt.%B, where A is one or two of Mg, Yb, Sc and In, B is CuO, Li 2 CO 3 , ZnO, Sm 2 o 3 , PbO and B 2 o 3 One or two of them, 0.12≤x≤0.49, 0.25≤y≤0.49, and 1-x-y≥0.10, 0≤a≤3;

[0030] The relaxation ferroelectric lead-based ceramic material with high phase transition temperature, excellent fatigue resistance and high electromechanical properties is developed along [001] c or[111] c Composed of grains with preferred orientation, the preferred orientation degree is above 90%;

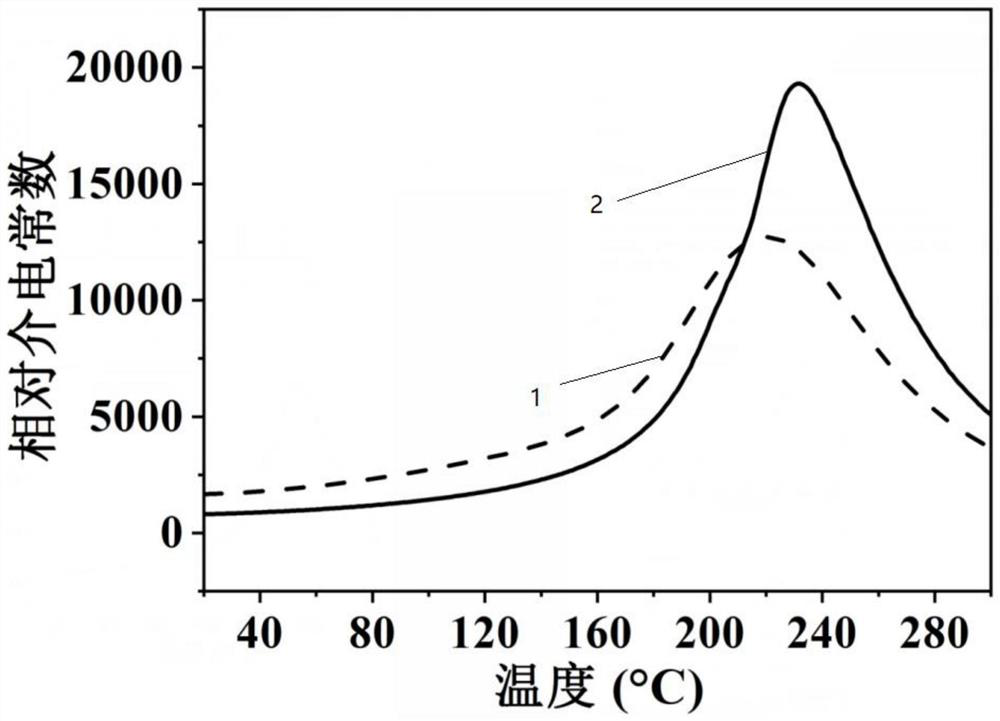

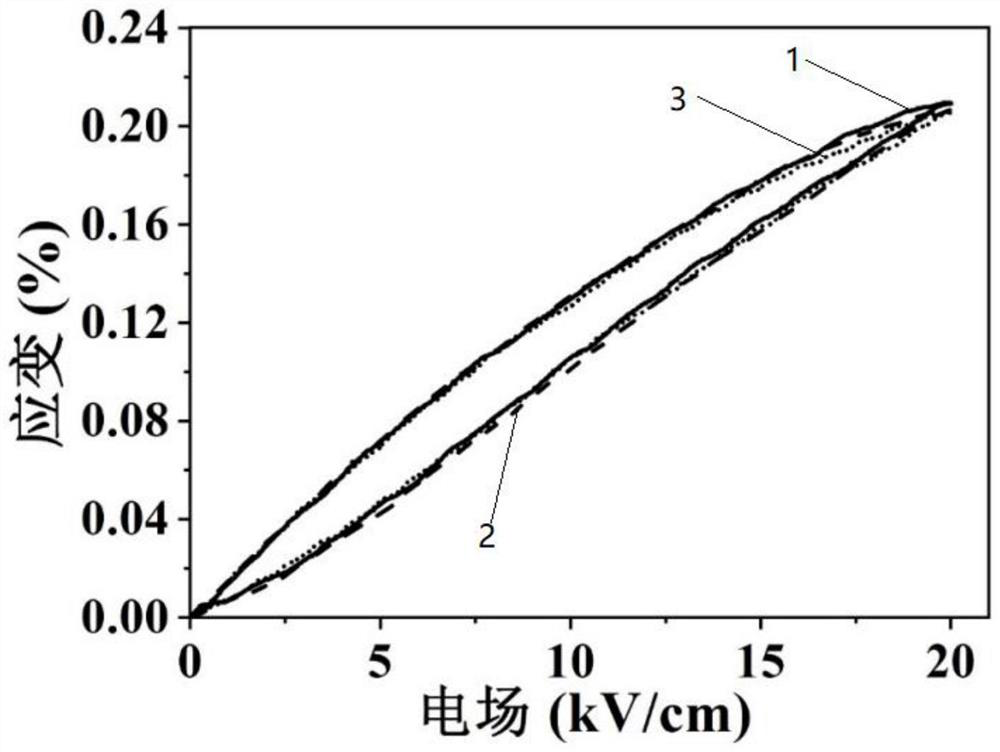

[0031] The trigonal-tetragonal phase transition temperature T of the relaxor ferroelectric lead-based ceramic material with high phase transition temperature, excellent fatigue resistance and high electromechanical prope...

specific Embodiment approach 2

[0033] Specific embodiment two: the preparation method of the relaxation ferroelectric lead-based ceramic material with high phase transition temperature, excellent fatigue resistance and high electromechanical performance in this embodiment, it is completed according to the following steps:

[0034] 1. Preparation of pure perovskite phase matrix fine powder:

[0035] ①. According to the general chemical formula, it is (1-x-y)Pb(A,Nb)O 3 -xPbZrO 3 -yPbTiO 3 - The stoichiometric ratio of awt.% B weighs PbO powder, material powder containing A and Nb, ZrO 2 Powder, TiO 2 Powder and sintering aid powder B; where 0.12≤x≤0.49, 0.25≤y≤0.49, and 1-x-y≥0.10, 0≤a≤3; the material powder containing A and Nb is MgNb 2 o 6 , YbNbO 4 , ScNbO 4 and InNbO 4 One or two of them; the sintering aid powder B is CuO, Li 2 CO 3 , ZnO, Sm 2 o 3 , PbO and B 2 o 3 one or both of them;

[0036] ②. Using absolute ethanol as the medium, symmetrically take PbO powder, material powder contain...

specific Embodiment approach 3

[0044] Specific embodiment three: the difference between this embodiment and specific embodiment two is: the PbO powder described in step one ①, the material powder containing A and Nb, ZrO 2 Powder, TiO 2 The purity of powder and sintering aid powder B is all greater than 99%; the ZrO described in step 1. 2 Powder and TiO 2 The particle size of the powder is less than 70nm. Others are the same as in the second embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Curie temperature | aaaaa | aaaaa |

| Piezoelectric constant | aaaaa | aaaaa |

| Piezoelectric constant | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com