Equipment and method for testing paper breakdown voltage of electrolytic capacitor

A technology of electrolytic capacitor paper and breakdown voltage, which is used in testing dielectric strength, instruments, measuring electricity, etc., can solve high-voltage electric shock casualties, affect the stability and repeatability of breakdown voltage value, and the test device does not restore the electrolytic capacitor. Breakdown and other problems to achieve the effect of improving stability and repeatability, avoiding manual recording of results, and avoiding frequent manual testing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] Below in conjunction with specific embodiment, further illustrate the present invention. It should be understood that these examples are only used to illustrate the present invention, not to limit the protection scope of the present invention. Improvements and adjustments made by those skilled in the art according to the present invention in practical applications still belong to the protection scope of the present invention.

[0045] In order to illustrate the present invention more conveniently, the present invention will be described in detail below in conjunction with the accompanying drawings.

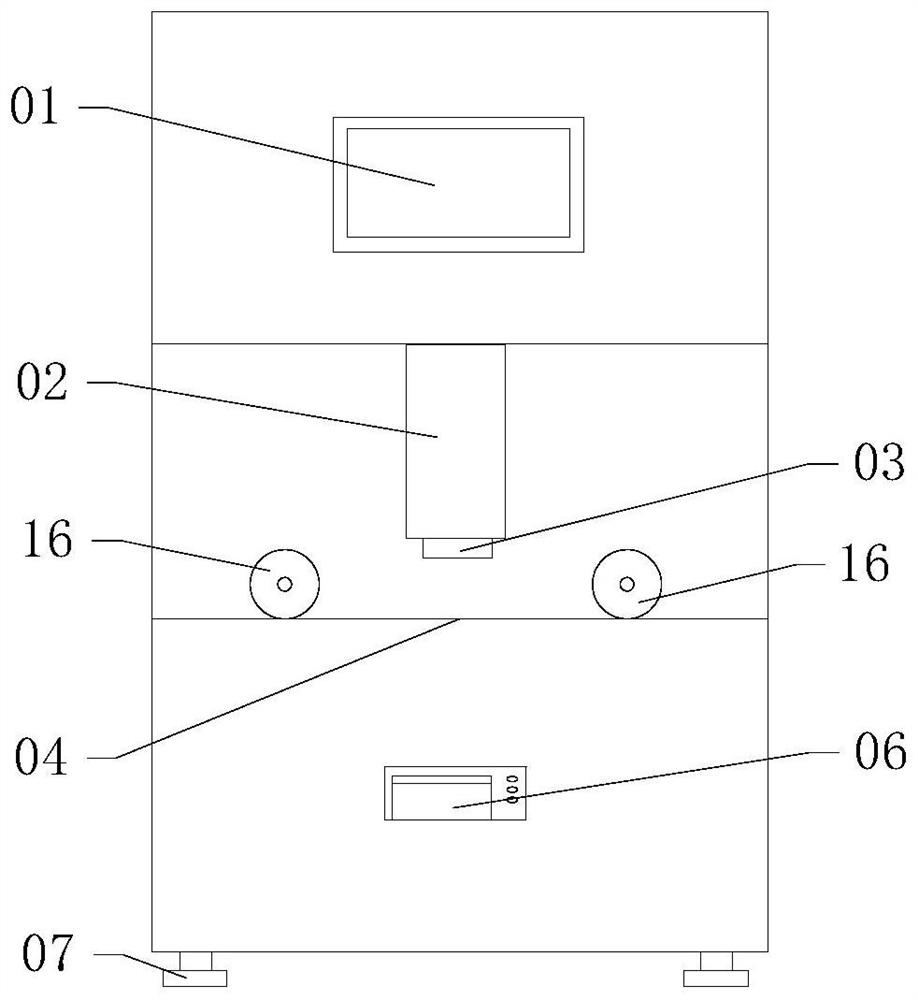

[0046] Such as figure 1 As shown, a kind of electrolytic capacitor paper breakdown voltage testing equipment comprises a rectangular frame, the bottom of the frame is provided with feet 07, the middle part of the frame is provided with a test bench 04, and the test bench 04 is used to place the to-be-tested Electrolytic capacitor paper.

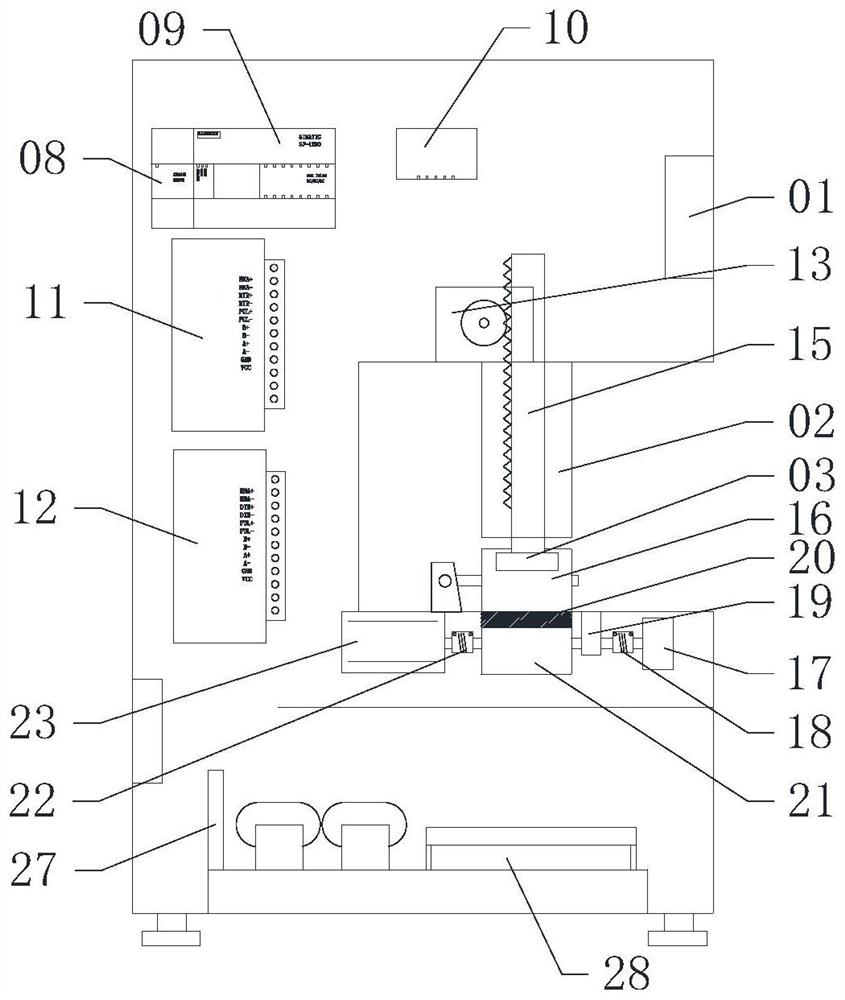

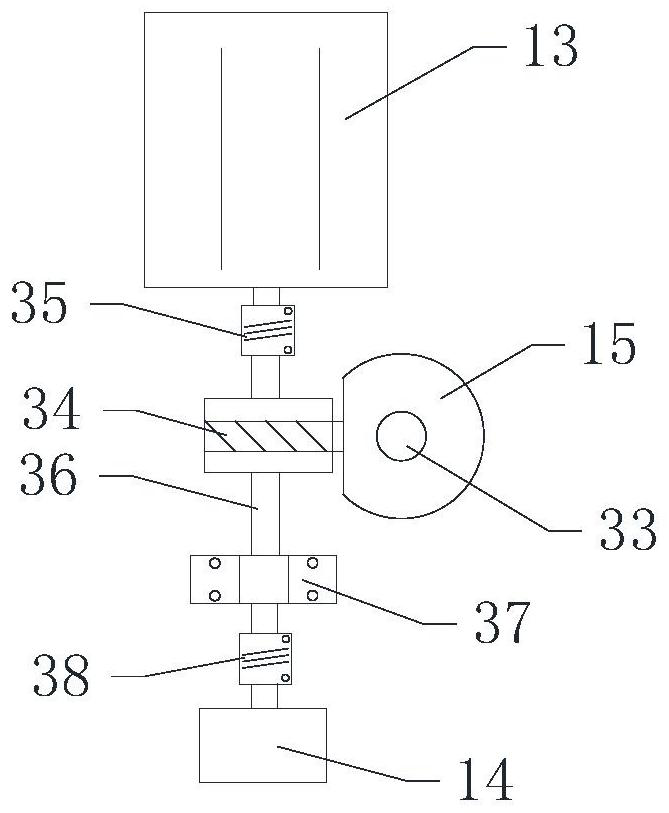

[0047] Such as figure 2 As sho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com