Light path calibration tool and method

An optical path and tool technology, applied in the field of optical path calibration tools, can solve the problems of inconvenient use, inaccurate light calibration, different aperture processing errors, etc., and achieve the effect of convenient use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

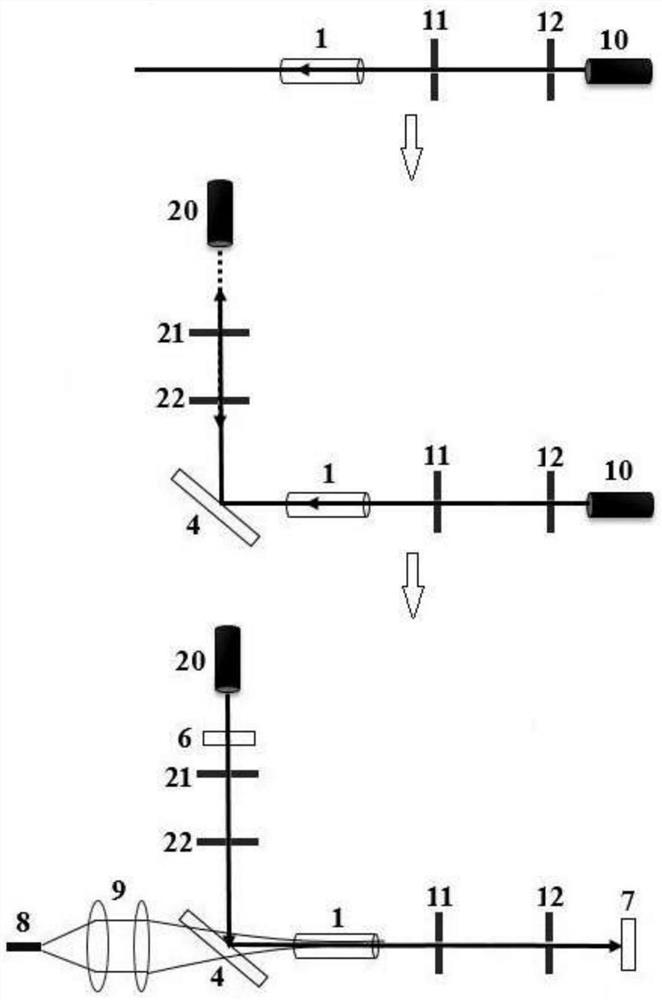

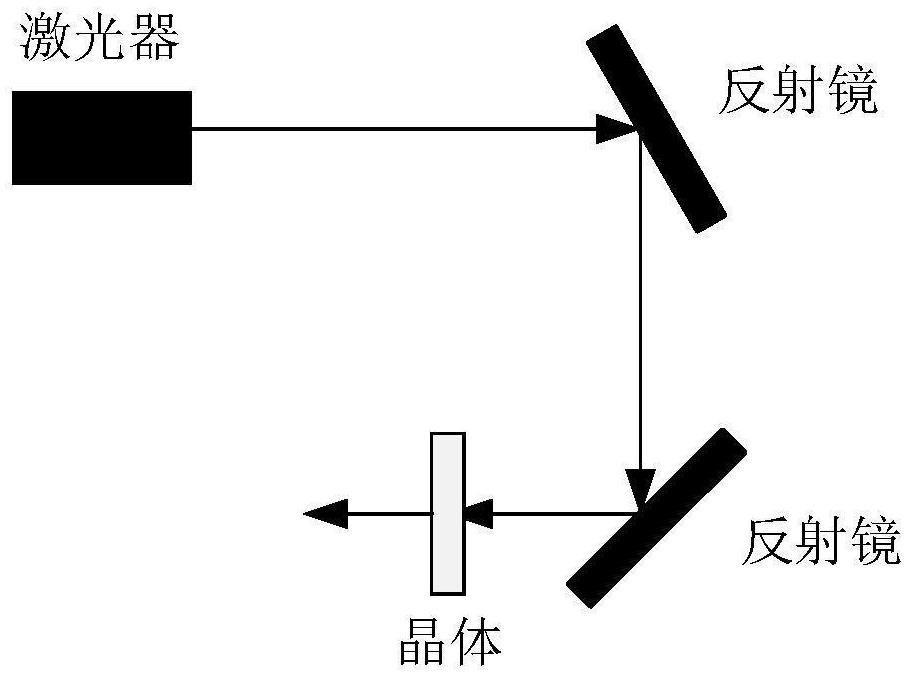

Method used

Image

Examples

Embodiment 1

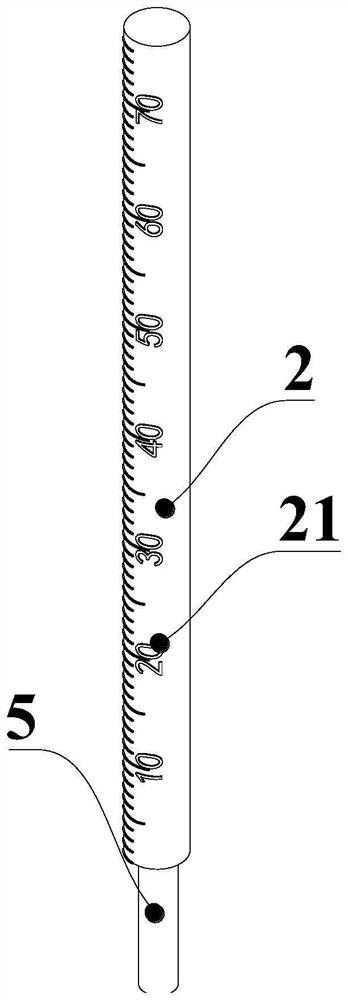

[0037] Such as figure 2 As shown, this embodiment provides an optical path calibration tool, which is suitable for quantum information-related optical experiments such as quantum communication and quantum measurement, and includes a fixed rod 5 and a calibration rod 2 coaxially arranged, and the diameter of the calibration rod 2 is the same as that of the The spot diameters are roughly the same; the fixed rod 5 can be plugged and fitted with the fixed hole of the optical table (not shown) in the axial direction, so that the calibration rod 2 is on the optical path to be calibrated and placed above the optical table.

[0038] Based on the above embodiments, the optical path calibration method provided in this embodiment includes the following steps:

[0039] Step A: Select a calibration rod 2 with the same diameter according to the spot size, and connect the selected calibration rod 2 to the fixed rod 5;

[0040] Step B: Insert the fixed rod 5 into the first section of the un...

Embodiment 2

[0057] refer to Figure 4 , in this embodiment, the optical path calibration tool also includes a mounting base 3 above the optical platform, the calibration rod 2 and the fixing rod 5 are vertically connected with the upper and lower end surfaces of the mounting base 3 respectively, and the fixing rod 5 is still in transition with the fixing hole at this time At this time, the diameter of the mounting base 3 is greater than the diameter of the fixing hole, thereby preventing the calibration tool from slipping from the fixing hole. The calibration rod 2 and the fixing rod 5 are coaxially arranged for optical path calibration. Since the mounting base 3 can be used to limit the position, the calibration rod 2 can be smaller than the diameter of the fixing hole, so Figure 4 The calibration tool shown is able to accommodate spots of arbitrary size.

[0058] The calibration method based on the calibration tool provided in this embodiment includes the following steps:

[0059] St...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com