Product analysis method, system and device and medium

A product analysis and product technology, applied in the field of intelligent manufacturing and artificial intelligence, can solve the problems of large influence of parameter elimination process threshold setting, difficult association rules, complex influence relationship, etc., to achieve strong flexibility and scalability, auxiliary adjustment and optimization , the effect of strong interpretability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

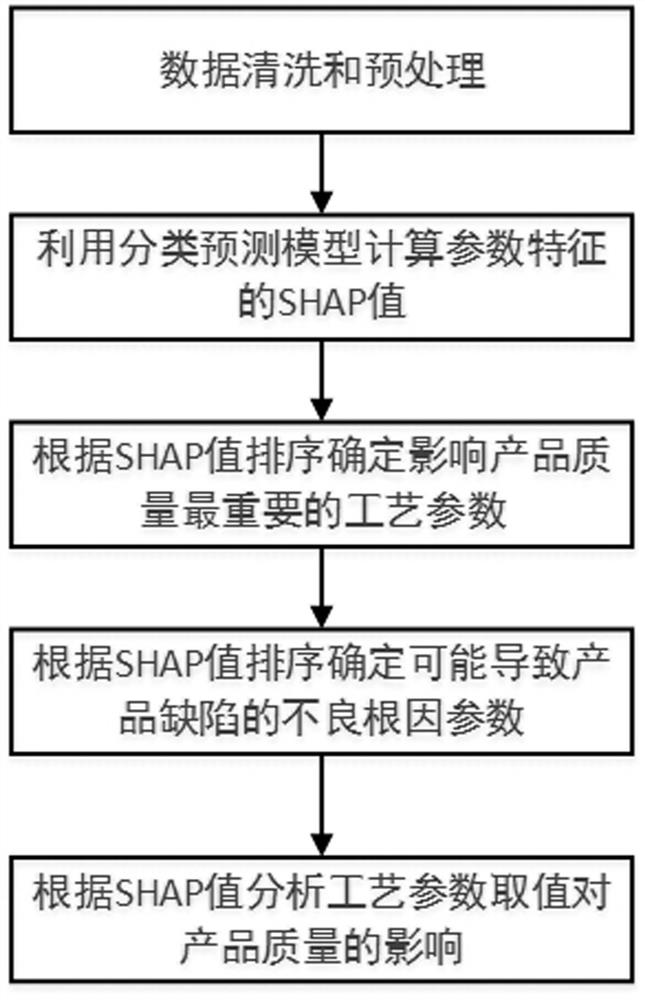

[0084] Please refer to figure 1 , figure 1 It is a schematic flow chart of a product analysis method, Embodiment 1 of the present invention provides a product analysis method, the method comprising:

[0085] Obtain the quality inspection data of the product, and label the quality inspection data to obtain the label data;

[0086] Obtaining the original processing data of the product, cleaning the original processing data to obtain first process flow data, and preprocessing the first process flow data to obtain second process flow data;

[0087] training the first classification prediction model based on the labeled data and the second process flow data to obtain a second classification prediction model;

[0088] Obtain the data to be analyzed, input the data to be analyzed into the second classification prediction model, and the second classification prediction model outputs the predicted value of each production process parameter in the data to be analyzed;

[0089] calcul...

Embodiment 2

[0149] On the basis of Embodiment 1, in order to more clearly demonstrate the purpose, technical solutions and advantages of the present invention, the following takes the problem of the root cause location of defective products in the production of glass panels as an example, and combines the accompanying drawings and specific embodiments to analyze the present invention. The invention is described in detail.

[0150] It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

[0151] Such as figure 1 Shown is a flow chart of a preferred embodiment of the method for locating the root cause of process defects of the present invention. According to different requirements, the order of some steps in the flow chart can be adjusted, and some steps can be omitted.

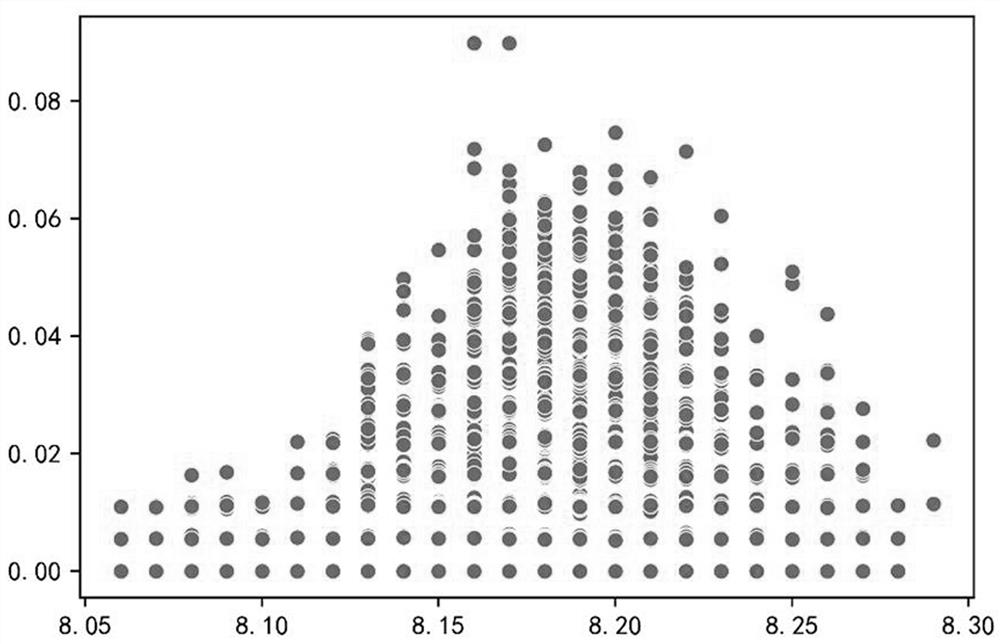

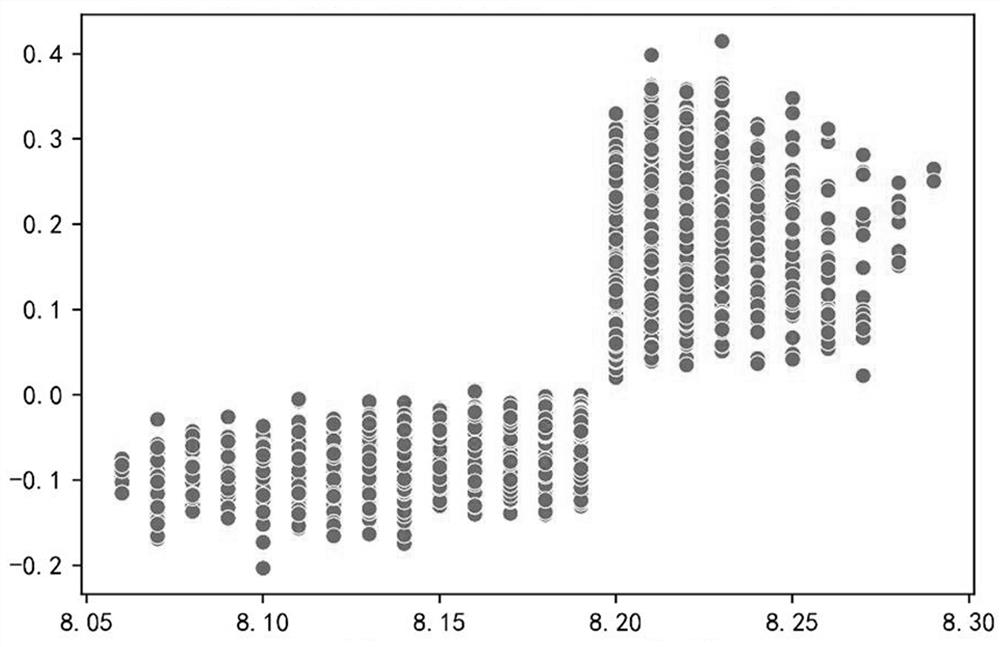

[0152] During the manufacturing process of glass panels, the fluctuation of the parameter values set by the process equipm...

Embodiment 3

[0221] The present invention provides a product analysis system in real time, please refer to Figure 4 , Figure 4 It is a schematic diagram of the composition of the product analysis system, and the system includes:

[0222] An annotation unit, configured to obtain quality inspection data of the product, and annotate the quality inspection data to obtain the annotation data;

[0223] The cleaning and preprocessing unit is used to obtain the original processing data of the product, clean the original processing data to obtain the first process flow data, and perform preprocessing on the first process flow data to obtain the second process flow data;

[0224] A training unit, configured to train the first classification prediction model based on the labeled data and the second process flow data to obtain a second classification prediction model;

[0225] A model processing unit, configured to obtain data to be analyzed, input the data to be analyzed into the second classific...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com