Material force field fitting method based on potential energy surface matching

A potential energy surface and force field technology, applied in the field of materials informatics, can solve problems such as being unsuitable for high-precision mechanical property analysis, and achieve the effects of saving experimental testing costs, less experimental data, and reducing computing time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

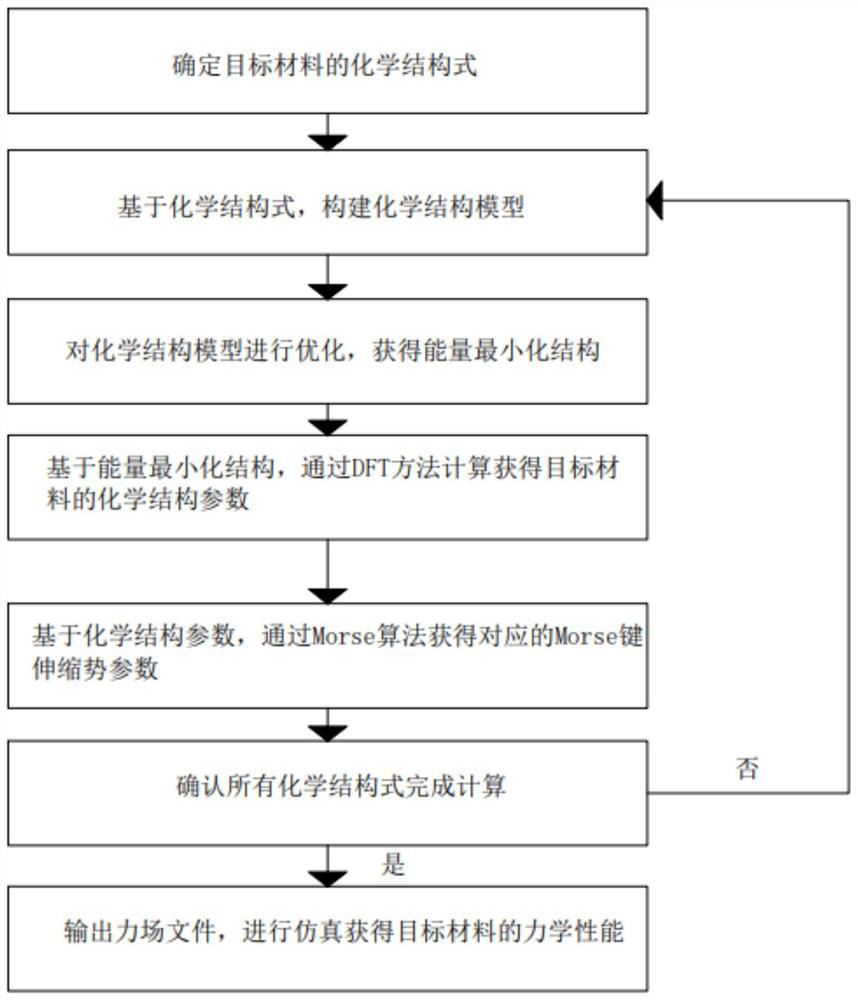

[0050] Such as figure 1 As shown, a material force field fitting method based on potential energy surface matching, the specific steps are:

[0051]S1 Obtain the corresponding chemical structural formula according to the target material: Take the fiber pre-oxidized silk model system containing C / H / O / N elements as an example. The chemical structural formula and corresponding bond types involved in this system are shown in Table 1:

[0052] The chemical structural formula contained in the embodiment of table 1 and the corresponding bond type

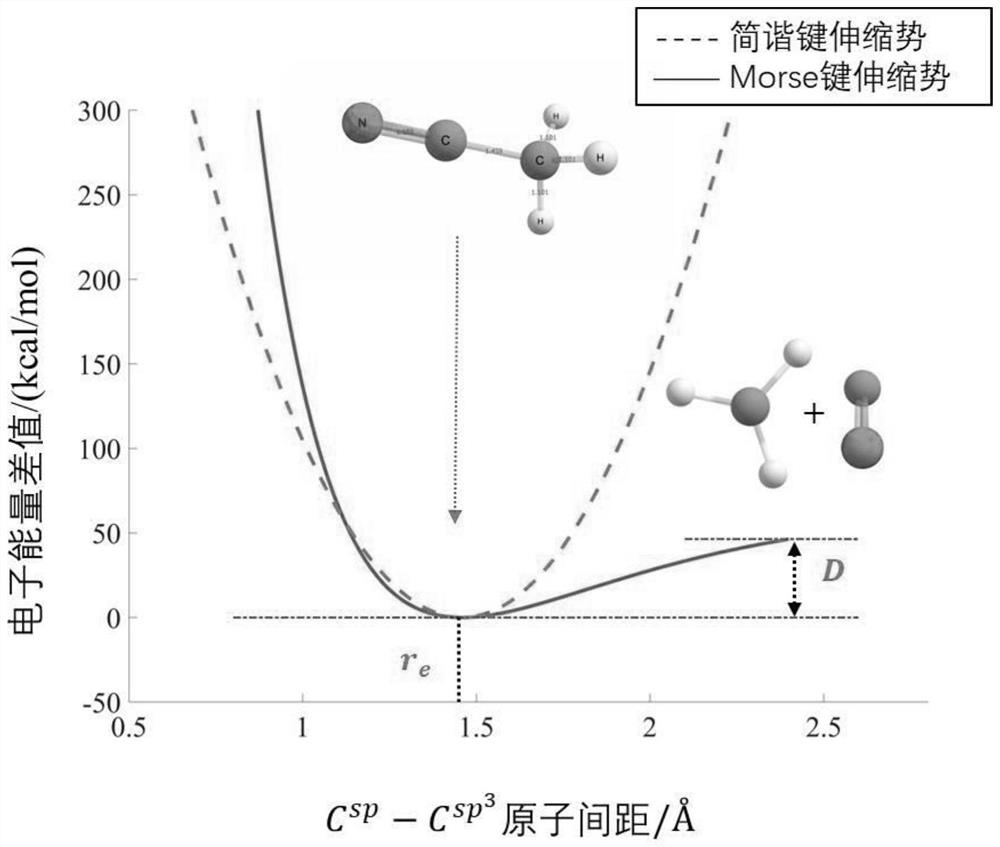

[0053] cluster model key type CH 3 CN

C sp -C sp3

HCN C sp -N sp

HC(O)H C sp2 -O sp2

CH 4

C sp3 -H

C 6 h 5 NH 2

C ring -N sp3

C 6 h 5 Oh

C ring -O sp3

C 6 h 6

C ring -C ring

C 6 h 6

C ring -H

C 5 h 5 N

C ring -N ring

NH 3

N sp3 -H

CH 3 Oh

o sp3 -H

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| breaking strength | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com