Photovoltaic module manufacturing equipment

A technology for manufacturing equipment and photovoltaic modules, which is applied in photovoltaic power generation, electrical components, semiconductor devices, etc., can solve problems affecting product performance and spread, and achieve the effects of preventing local damage, uniform force, and improving strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The subject matter described herein will now be discussed with reference to example implementations. It should be understood that the discussion of these implementations is only to enable those skilled in the art to better understand and realize the subject matter described herein, and is not intended to limit the protection scope, applicability or examples set forth in the claims. Changes may be made in the function and arrangement of elements discussed without departing from the scope of the disclosure. Various examples may omit, substitute, or add various procedures or components as needed. Additionally, features described with respect to some examples may also be combined in other examples.

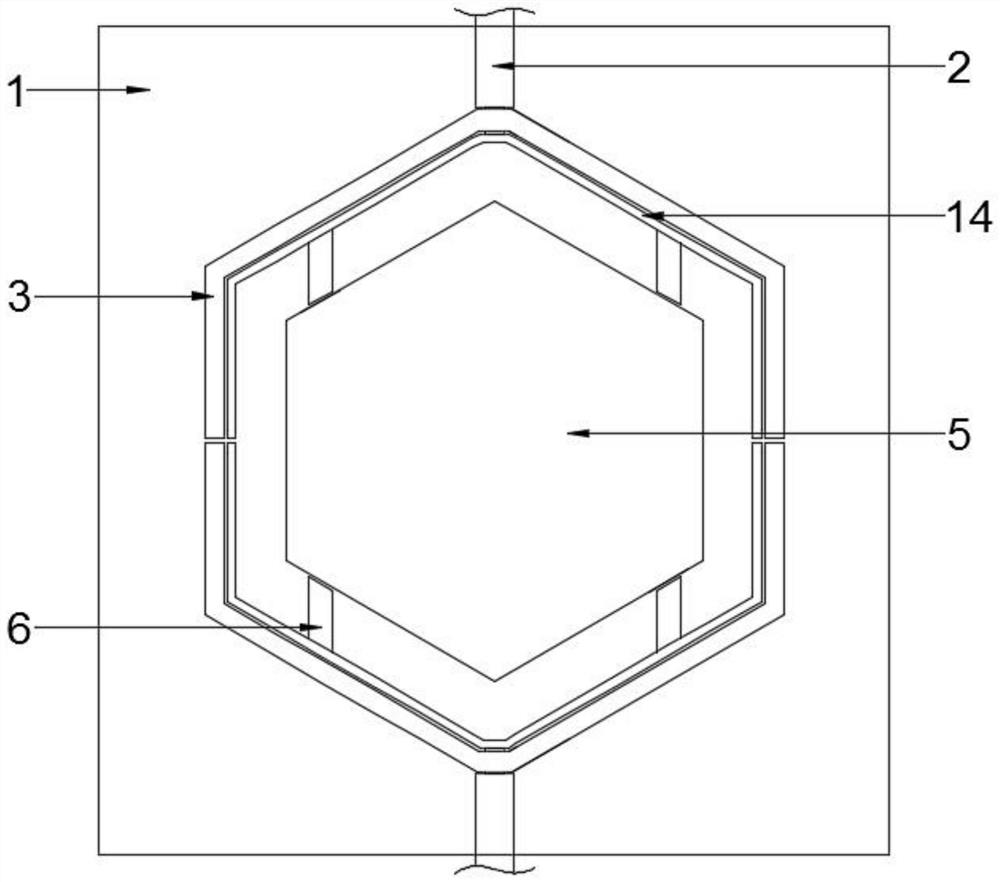

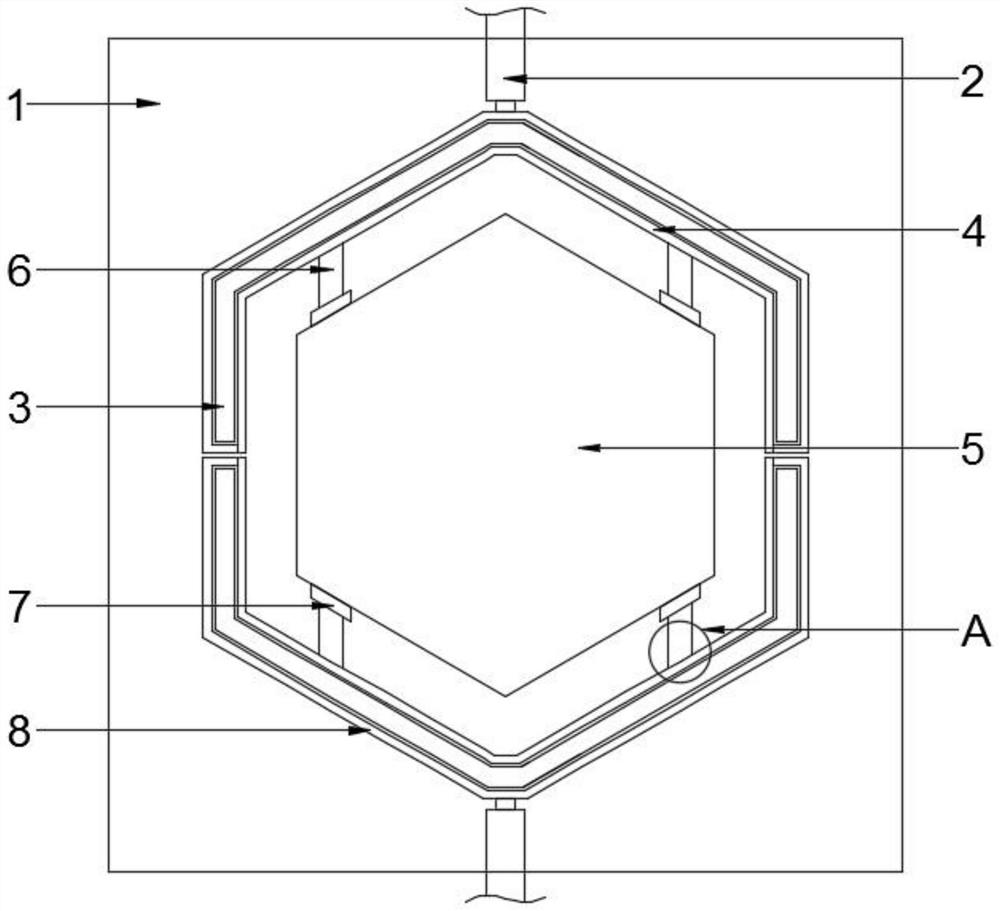

[0033] A photovoltaic module manufacturing equipment, see figure 1 , including a workbench and a glue filling mechanism. During glue filling, the outer layer plate 1 and the cells 5 between the outer layer plates 1 are located on the workbench, and are filled and packaged by ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com