Multi-cooling-channel motor

A cooling flow and flow channel technology, which is applied in the field of multi-cooling flow channel motors, can solve the problems affecting the life and safety of the motor, the increase in heating temperature, and the low heat dissipation efficiency of the motor casing, so as to reduce the temperature and achieve high-efficiency working conditions. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be described in further detail below.

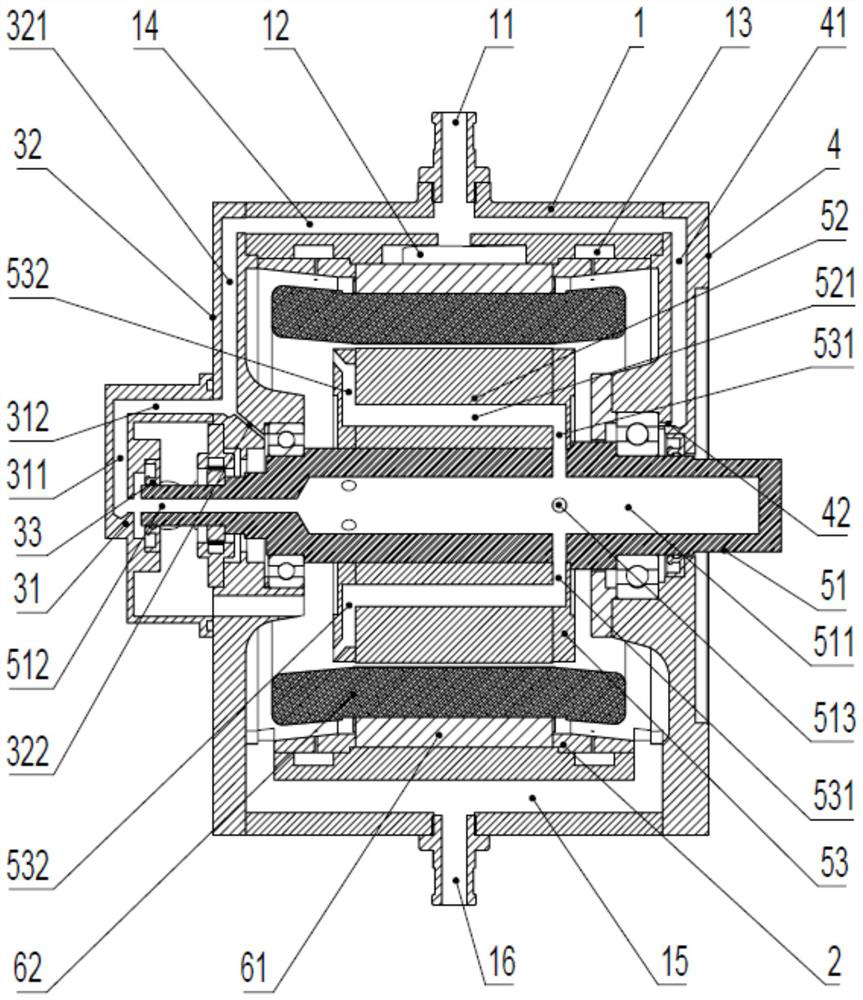

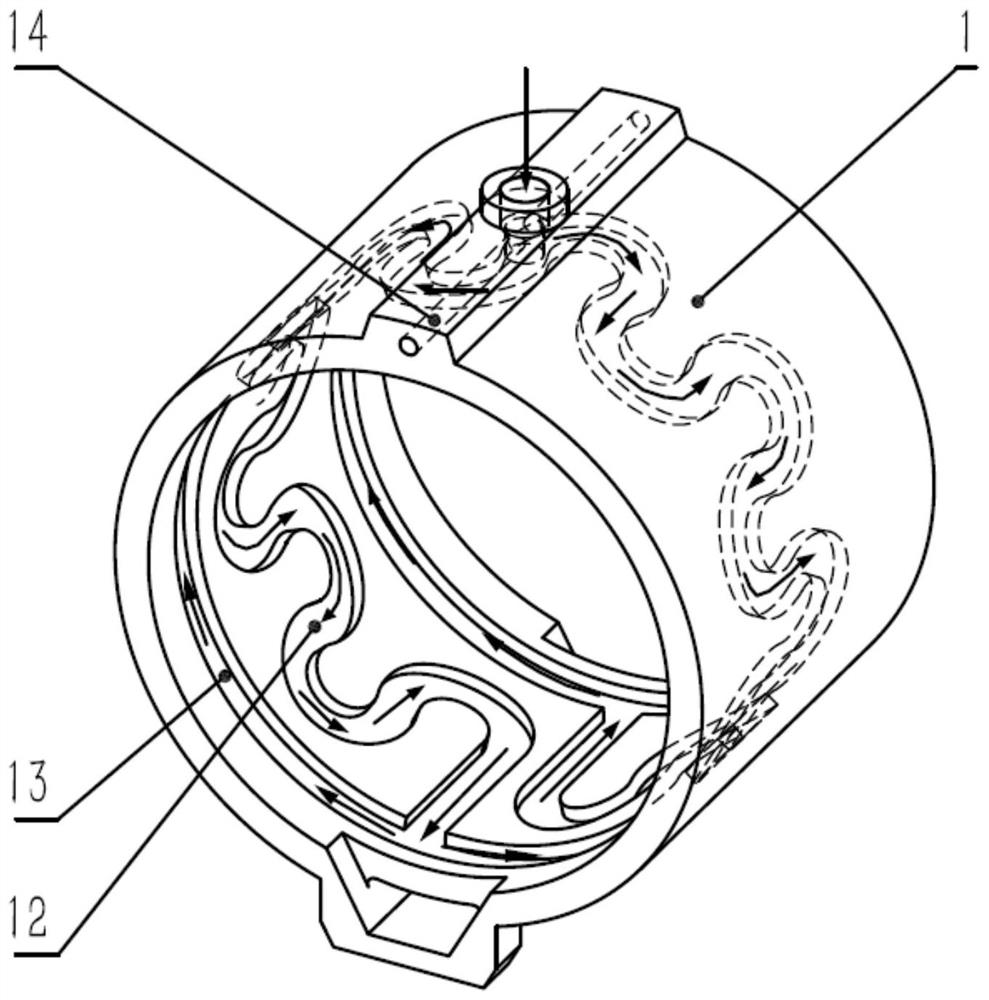

[0036] like figure 1 As shown, a multi-cooling channel motor includes a casing 1, a stator and a rotor, the stator is provided with a stator core 61 and a winding 62, and the casing 1 is provided with a coolant inlet 11, an arc-shaped flow channel and a coolant outlet 16 , the arc-shaped flow channel is arranged around the casing 1, the arc-shaped flow channel is connected to the stator core 61, the rotor is provided with a rotor flow channel, and both the rotor flow channel and the arc-shaped flow channel are connected with the coolant inlet 11 and the coolant outlet 16, The rotor flow path and the arc flow path correspond to the ends of the winding 62 respectively.

[0037] Specifically, after the cooling liquid enters through the cooling liquid inlet 11 of the casing 1, a part of the cooling liquid enters the arc-shaped flow channel arranged around the casing 1 to cool the casing 1 and the stator cor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com