Printed circuit board and manufacturing method thereof

A printed circuit board and manufacturing method technology, applied in the directions of printed circuit manufacturing, laminated printed circuit boards, printed circuits, etc., can solve the problems of different branch or signal width, low work efficiency, inconvenient operation, etc., to reduce processing Steps, testing convenience, and the effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

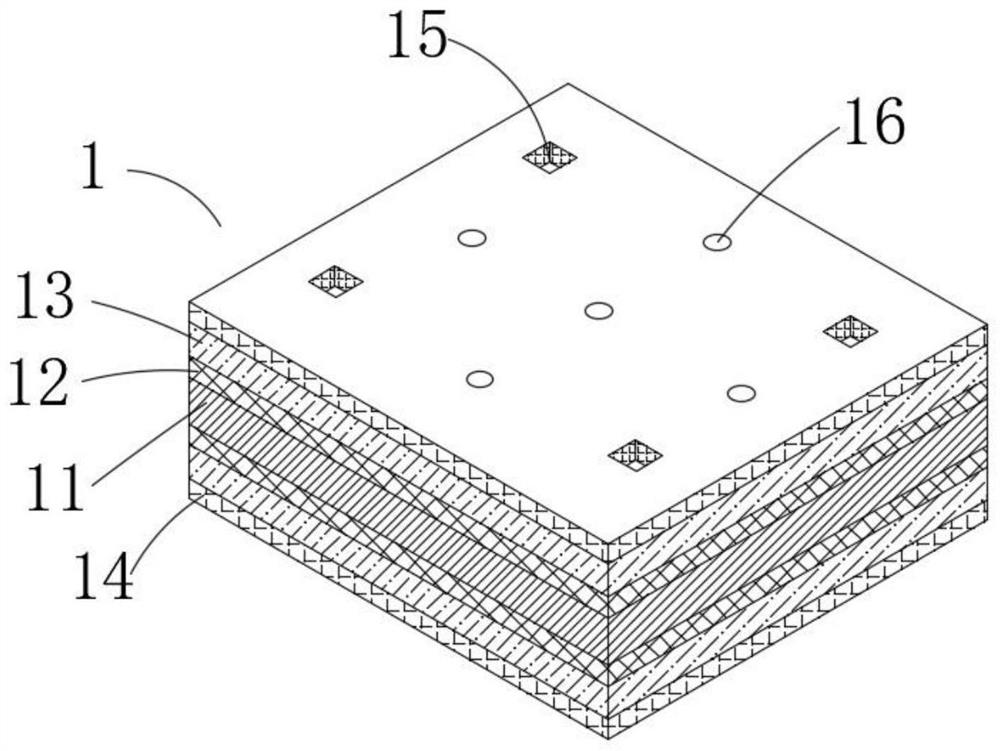

[0027] Such as figure 1 As shown, a printed circuit board proposed by the present invention includes a circuit board body 1, and the circuit board body 1 includes a core board 11. Prepregs 12 are provided on both sides of the core board 11, and copper foil is connected to the other side of the prepreg 12. 13. An aluminum plate 14 is provided on the other side of the copper foil 13. A blind hole 15 is opened on the aluminum plate 14. A signal hole 16 is opened on the circuit board body 1. The signal hole 16 runs through the circuit board body 1, and the inside of the signal hole 16 is coated with Has an antioxidant layer.

[0028] In this embodiment, a printed circuit board is composed of a core board 11, a prepreg 12, a copper foil 13, and an aluminum plate 14. The setting of the signal hole 16 improves the stability of the circuit board body 1 when performing signal transmission detection, and the signal transmission is stable. The difference is reduced.

Embodiment 2

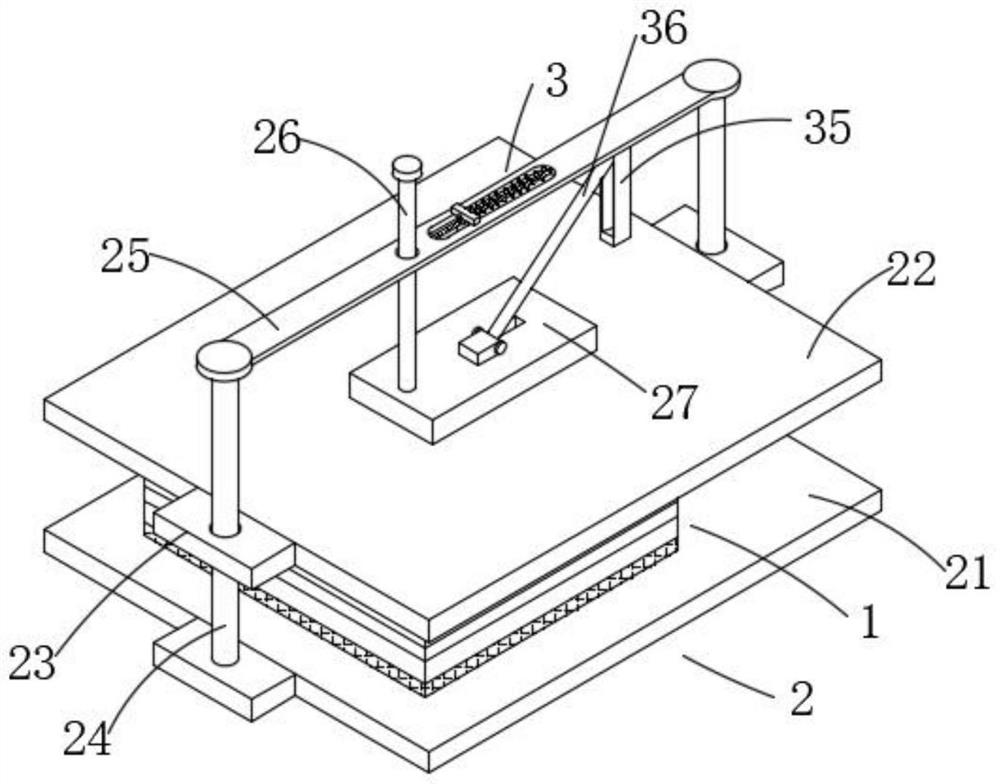

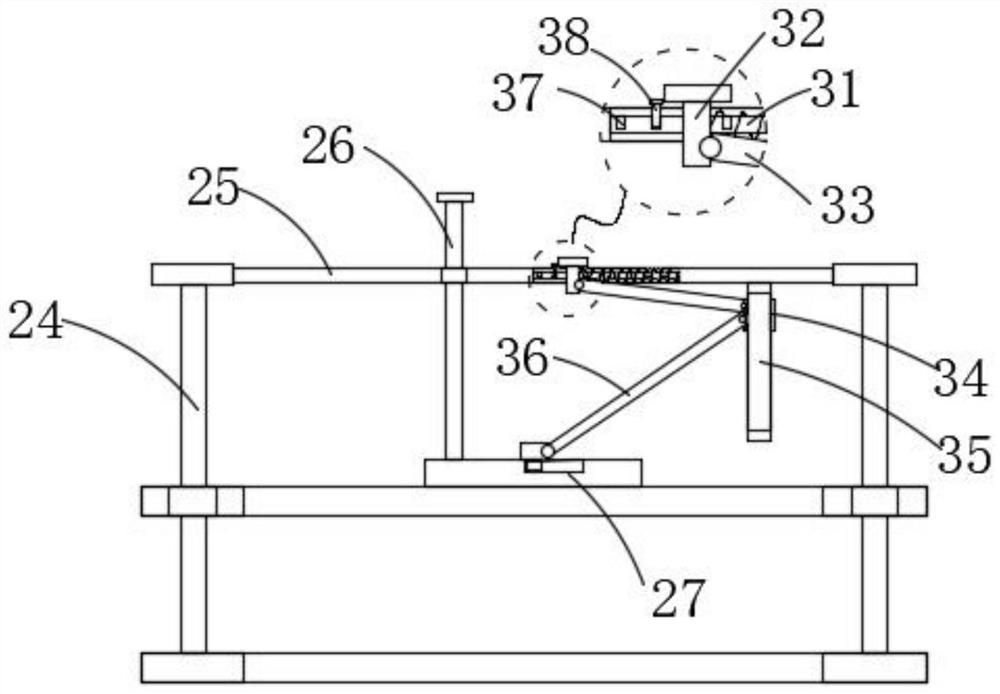

[0030] Such as Figure 2-3 As shown, a printed circuit board proposed by the present invention, compared with the first embodiment, this embodiment also includes: a circuit board body 1, the circuit board body 1 uses a pressing mechanism 2 in the pressing process, and the pressing An adjustment mechanism 3 is provided on the mechanism 2. Furthermore, the present invention also proposes a method for manufacturing a printed circuit board, which includes the following steps:

[0031] S1. Material preparation: pre-preparing and processing the component parts of each layer of the circuit board, the component parts include the core board 11, the prepreg 12, the copper foil 13 and the aluminum plate 14;

[0032] S2. Punching and pressing: laying and stacking the core board 11, the prepreg 12, the copper foil 13 and the aluminum plate 14 in sequence, and positioning and pressing through the pressing mechanism 2;

[0033] S3. Hole treatment: drilling the circuit board body 1 with a dr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com