High-temperature-resistant and high-pressure-resistant medical sterilization bag and preparation method thereof

A sterilization bag, high temperature resistant technology, applied in bags, sacks, bag making operations, etc., can solve the problems of inconvenience, bacterial infection of unused instruments, and easy generation of particles, etc., to achieve convenient use, wide application range, good limit bit and the effect of protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be specifically introduced below in conjunction with the accompanying drawings and specific embodiments.

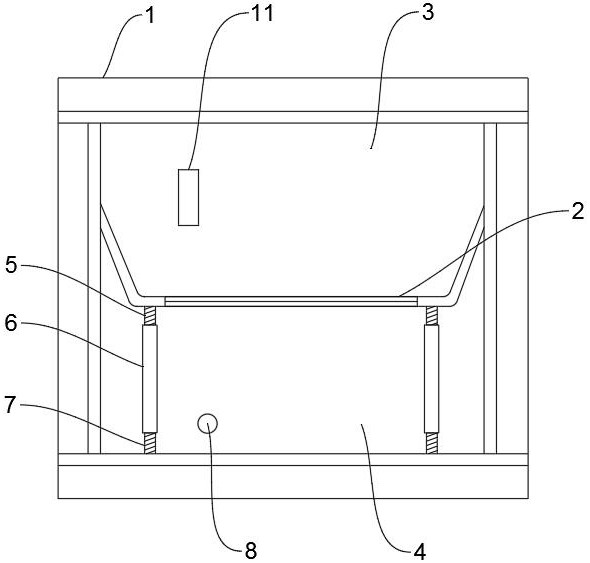

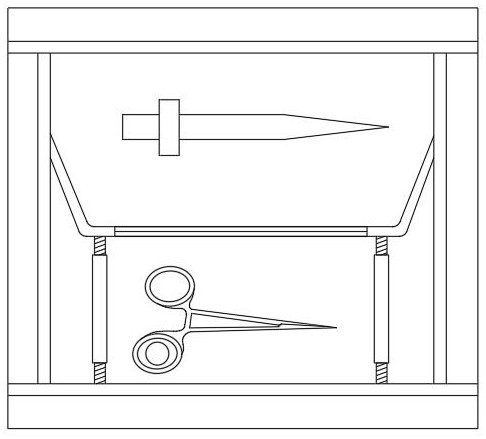

[0026] see Figure 1~3 , a high temperature and high pressure resistant medical sterilization bag of the present invention, comprising a sterilization bag main body 1, the sterilization bag main body 1 includes a first main film and a second main film, and the four edges of the first main film and the second main film Both are heat-sealed together.

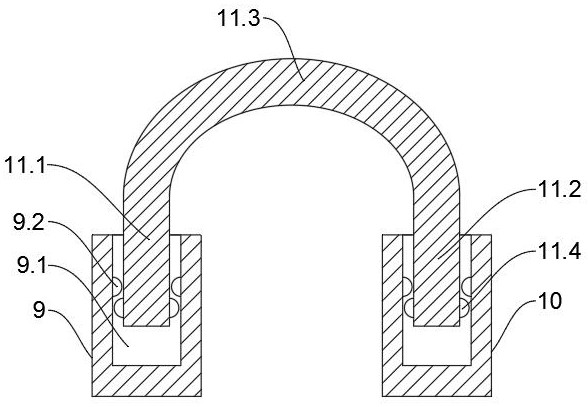

[0027] The inside of the sterilization bag main body 1 is provided with a partition 2, which divides the interior of the sterilization bag main body 1 into an upper storage chamber 3 and a lower storage chamber 4, and the partition 2 includes a first diaphragm and a second diaphragm, the first The tops of the diaphragm and the second diaphragm are respectively glued to the inner upper parts of the first main film and the second main film, and the bottoms and both sides of the first diaphragm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com