Feeding device for production and processing of magnetic conductive tubes of gearboxes

A gearbox and magnetic conduction technology, which is applied in the direction of transportation and packaging, vibrating conveyors, conveyor objects, etc., can solve the problems of magnetic tube drop, affect the normal processing and use of goods, and the efficiency of transshipment is not high, so as to reduce work Strength, ensure stability, and improve work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In order to further explain the technical means and effects of the present invention to achieve the intended purpose of the invention, the specific implementation, structure, features and effects of the present invention will be described in detail below in conjunction with the accompanying drawings and preferred embodiments.

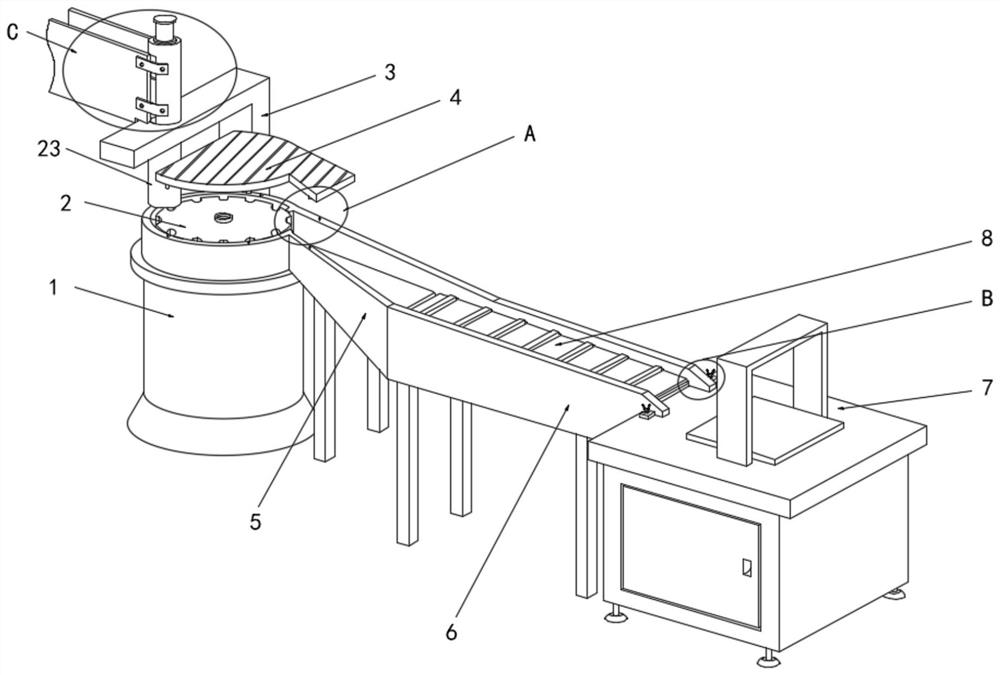

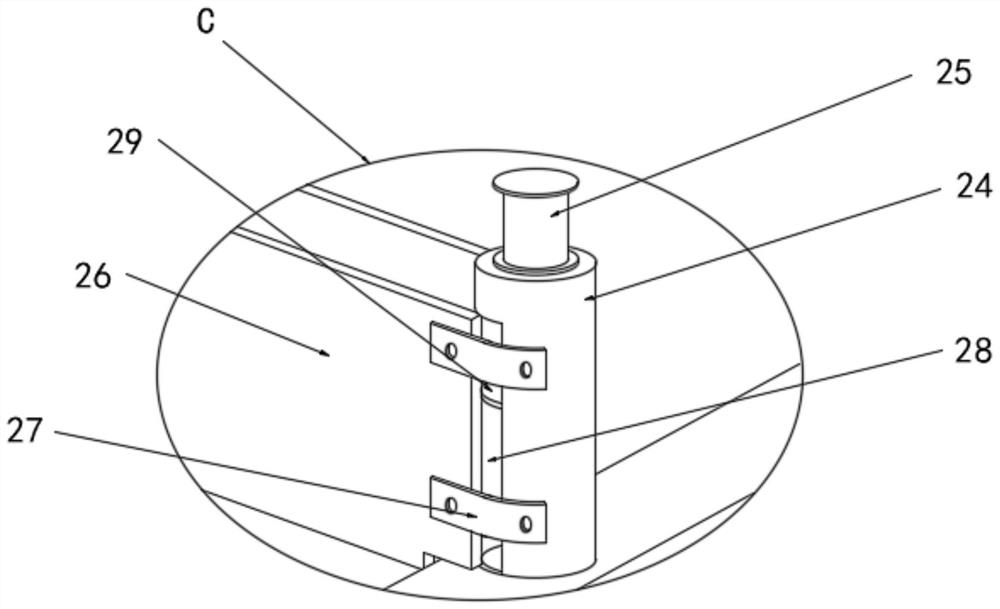

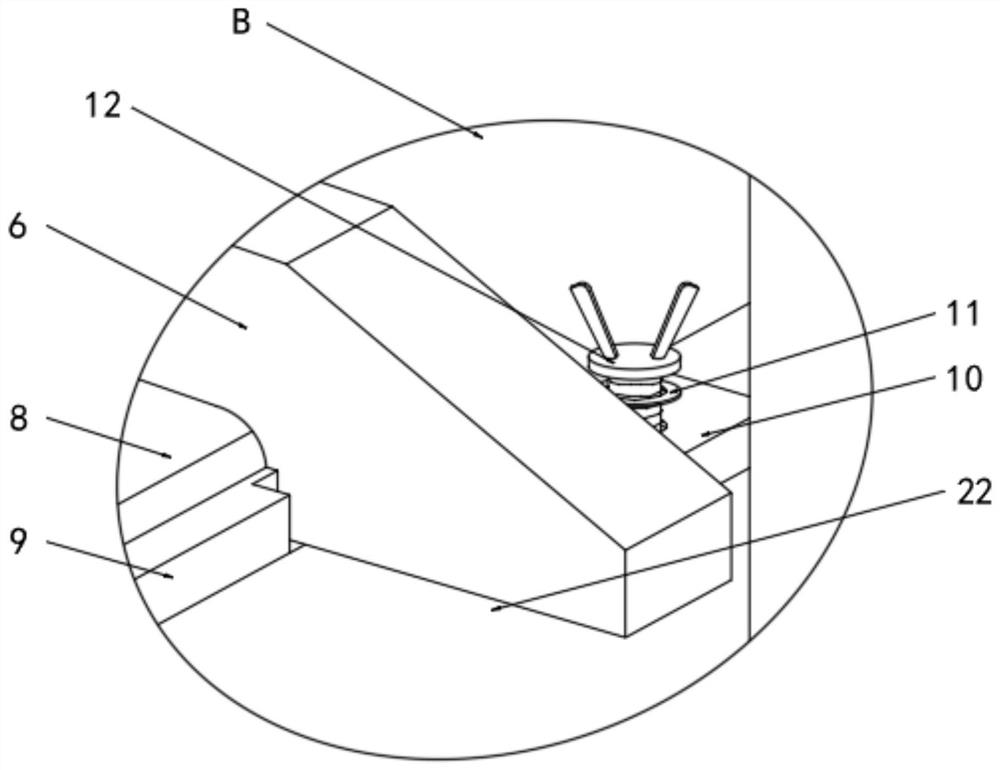

[0025] see Figure 1-Figure 5 As shown, the present invention provides a feeding device for the production and processing of magnetic tubes for gearboxes, including a deflection table 1, one side of the deflection table 1 is connected with a transmission frame 6, and one side of the transmission frame 6 is connected with a processing platform 7, and the connection between the transmission frame 6 and the deflection table 1 is provided with a vibrating chamber 5, the inside of the deflection table 1 is connected to the rotation frame 2, and the top of the deflection table 1 is provided with a feeding frame 3, and the outer surface of the rotation f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com