Prefabricated stair with steps capable of being spliced for use and construction method for splicing steps

A construction method and stair technology, which are applied in the directions of stairs, tread and vertical plate units, and building materials processing, etc., can solve the problems of long concrete curing time, inconvenient use, complicated process, etc., and achieve easy construction technology, low operation difficulty, weight reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The core of the present invention is to provide a prefabricated staircase with assembled steps and a construction method for assembling steps, so as to reduce the maintenance time, speed up the construction process, and reduce the generation of construction waste; improve the prefabricated precision of the stairs, and can be used for mass production; at the same time, In places with dense traffic, when the stairs are damaged, the steps can be replaced flexibly, which avoids the impact on the use of stairs due to the long concrete curing period and harsh curing environment.

[0035] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

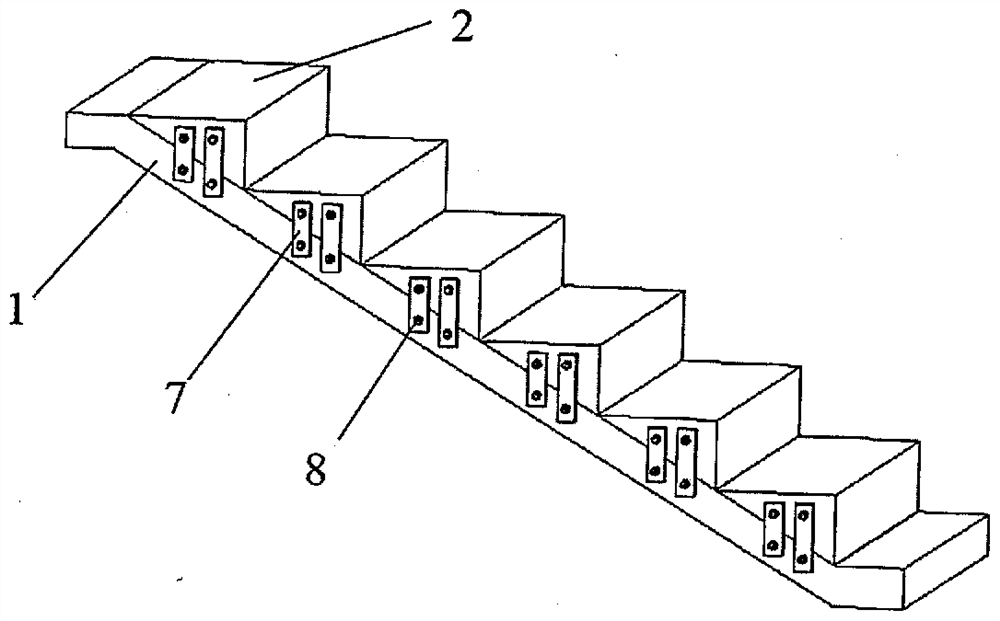

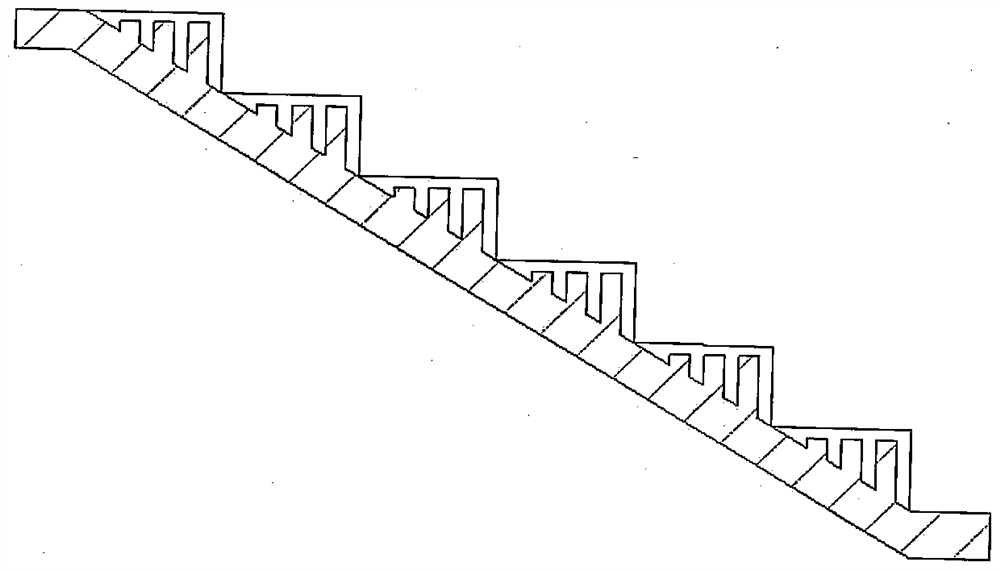

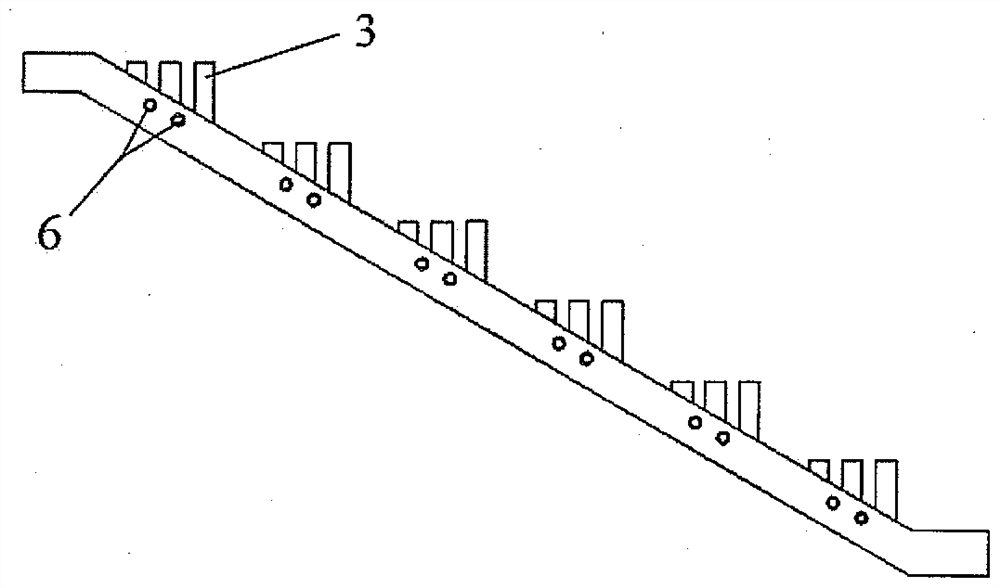

[0036] Please refer to Figure 1-Figure 8 The present invention provides a prefabricated staircase with steps that can be assembled and used, including a prefabricated stair base 1, a prefabricated step 2, a steel plate 7 for connection and fixation, a high-strengt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com