Mechanical arm for heading machine and heading machine

A technology of robotic arms and roadheaders, which is applied in mining equipment, tunnels, earth-moving drilling, etc., can solve problems such as the inability to effectively treat the sidewall of the tunnel, and achieve the effect of improving the construction scope and space, diverse functions, and a wide range of applications.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

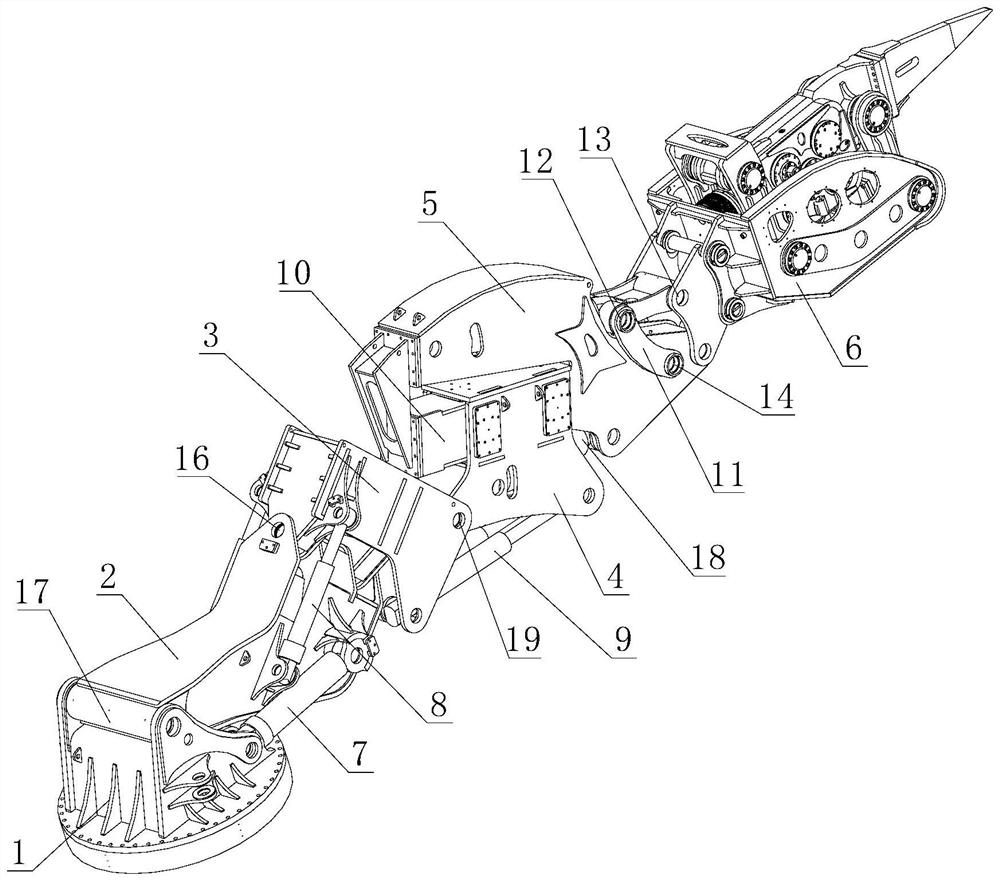

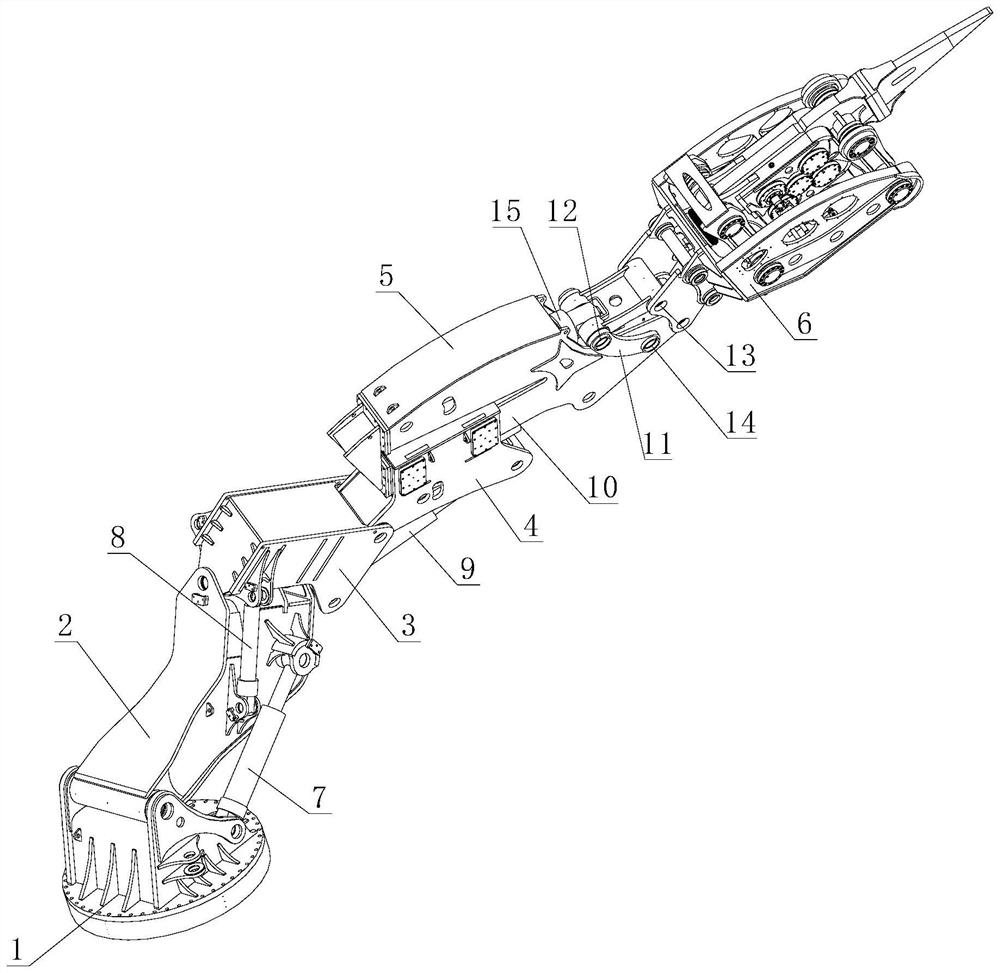

[0026] An embodiment of the present invention is, as figure 1 As shown, the base of the mechanical arm 1 is hinged with the flip connection seat 3 through the first hinge point 16, and the other end of the flip connection seat 3 is provided with a driving device 6, and the flip connection seat 3 can be positioned relative to the The base 1 of the mechanical arm is turned sideways.

[0027] A first rotating base 2 is connected between the base 1 of the mechanical arm and the flipping connecting seat 3, and the first rotating base 2 is connected with the base 1 of the mechanical arm through a first rotating shaft 17. The first rotating base 2 The other end of the first hinge point 16 is hinged with the flip connection seat 3, and the first hinge point 16 is arranged on the long axis of the mechanical arm, so that the excavation device 6 can be turned left and right; the mechanical arm base 1 and the second The first telescopic oil cylinder 7 is connected between the first rotat...

Embodiment 2

[0031] Such as Figure 2-3 As shown, it is another embodiment of the present invention. On the basis of Embodiment 1, this embodiment adds the forward and backward movement function of the driving device 6, that is, the driving device 6 can be moved relative to the mechanical arm base 1 Moving back and forth, in this embodiment, the tunneling device 6 can move back and forth 0.5m in the direction of tunneling, so as to improve the strength and efficiency of tunneling.

[0032]Specifically, a mobile base 4 is provided between the turning connection base 3 and the tunneling device 6, and one end of the moving base 4 is connected to the turning connection base 3 through a second rotating shaft 19, and the second rotating shaft 19 can make The moving base 4 can rotate up and down with the second rotating shaft 19 as the center of a circle, and the driving device 6 is arranged on the moving base 4 , and the driving device 6 can slide back and forth relative to the moving base 4 . ...

Embodiment 3

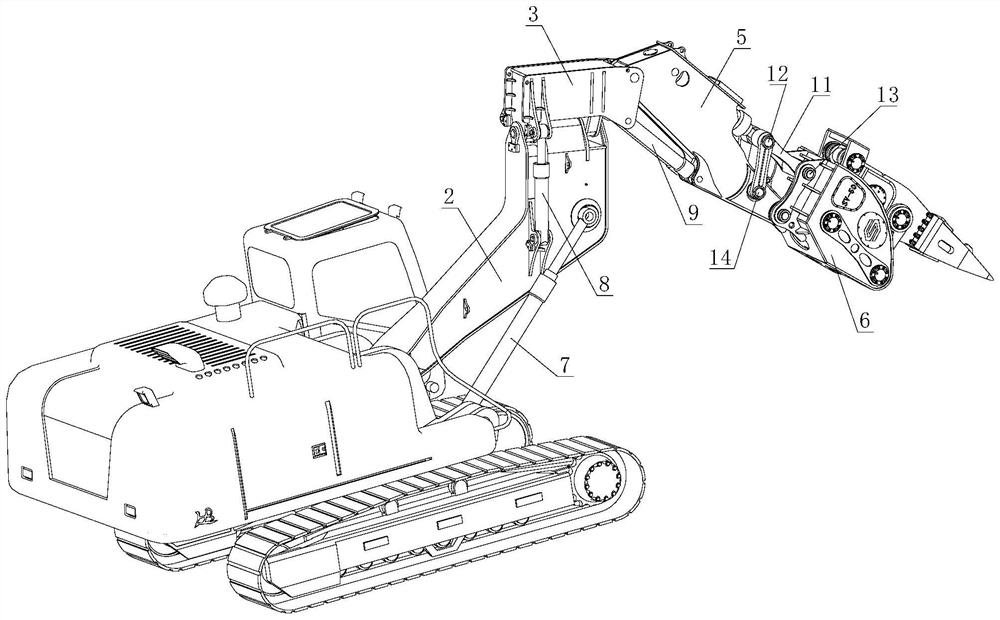

[0038] In this embodiment, a roadheader is provided. The roadheader in this embodiment includes any mechanical arm for a roadheader in Embodiment 1 or Embodiment 2 above, and the mechanical arm for a roadheader is combined on the roadheader or It is used on the trolley, specifically, the mechanical arm of the roadheader is arranged on the body of the roadheader. The body of the roadheader is the body of the existing roadheader, or it can be a construction trolley. When the main body rotates, when the mechanical arm of the roadheader is set on the existing roadheader or construction trolley, the entire mechanical arm of the roadheader can be driven to rotate left and right or up and down through a rotating mechanism or a telescopic mechanism (such as a telescopic oil cylinder) , thereby increasing the construction range of the mechanical arm of the roadheader and improving the flexibility of the construction of the mechanical arm of the roadheader.

[0039] A further technical ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com